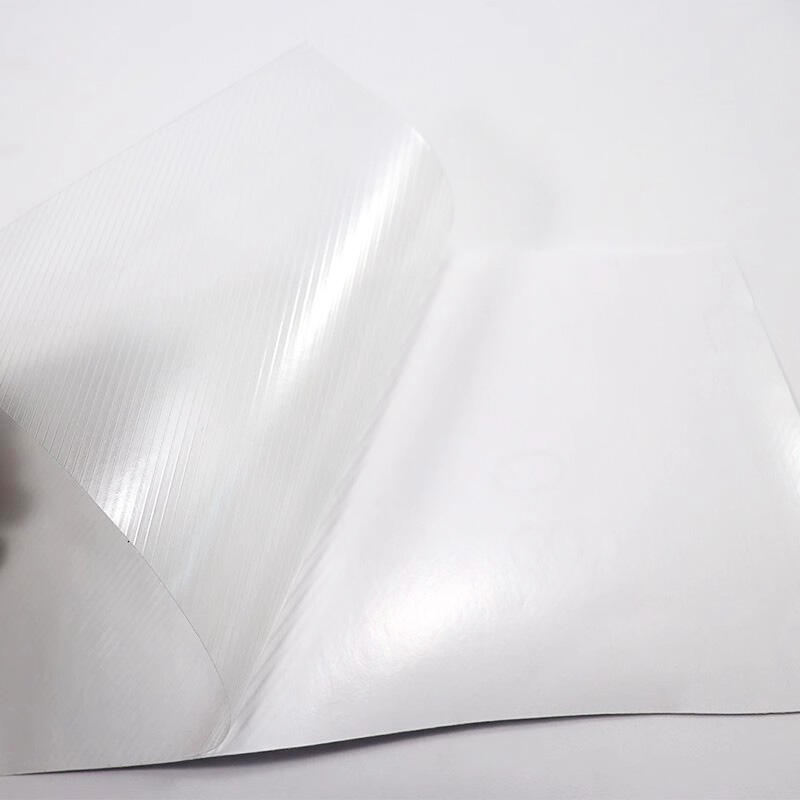

Seamless Hygienic Surface Design

The printing floor features an innovative seamless surface design that revolutionizes cleanliness and hygiene standards in printing facilities while dramatically reducing maintenance requirements and operational costs. This seamless construction eliminates the joints, seams, and crevices present in traditional flooring systems where contaminants, bacteria, and debris typically accumulate, creating breeding grounds for microorganisms and sources of contamination that can affect product quality and workplace health. The printing floor seamless surface is created through advanced application techniques that produce a continuous, monolithic surface without weak points or areas prone to failure. This design approach ensures that the entire floor functions as a single, integrated system rather than multiple components that can separate or fail independently. The seamless nature of the printing floor prevents liquid penetration and eliminates the need for grout lines or sealants that require regular maintenance and eventual replacement. Cleaning procedures for the seamless printing floor are simplified to basic sweeping and mopping operations using standard equipment and cleaning solutions, eliminating the need for specialized tools or harsh chemicals required to maintain traditional flooring systems with joints and seams. The smooth, non-porous surface prevents the absorption of stains, odors, and contaminants that typically penetrate porous flooring materials, maintaining a fresh, professional appearance throughout the floor's service life. The printing floor seamless design meets the highest hygiene standards required in facilities where cleanliness directly impacts product quality, such as food packaging printing or pharmaceutical labeling operations. The continuous surface eliminates hiding places for insects and rodents, supporting integrated pest management programs and reducing the risk of contamination from biological sources. Maintenance costs are significantly reduced because the seamless printing floor requires no grout cleaning, seal replacement, or joint repair that consume time and resources in facilities with traditional flooring systems. The hygienic properties of the seamless printing floor contribute to improved indoor air quality by preventing the accumulation of dust, allergens, and volatile compounds in floor joints and crevices.