The Ultimate Guide to Professional Vinyl Installation

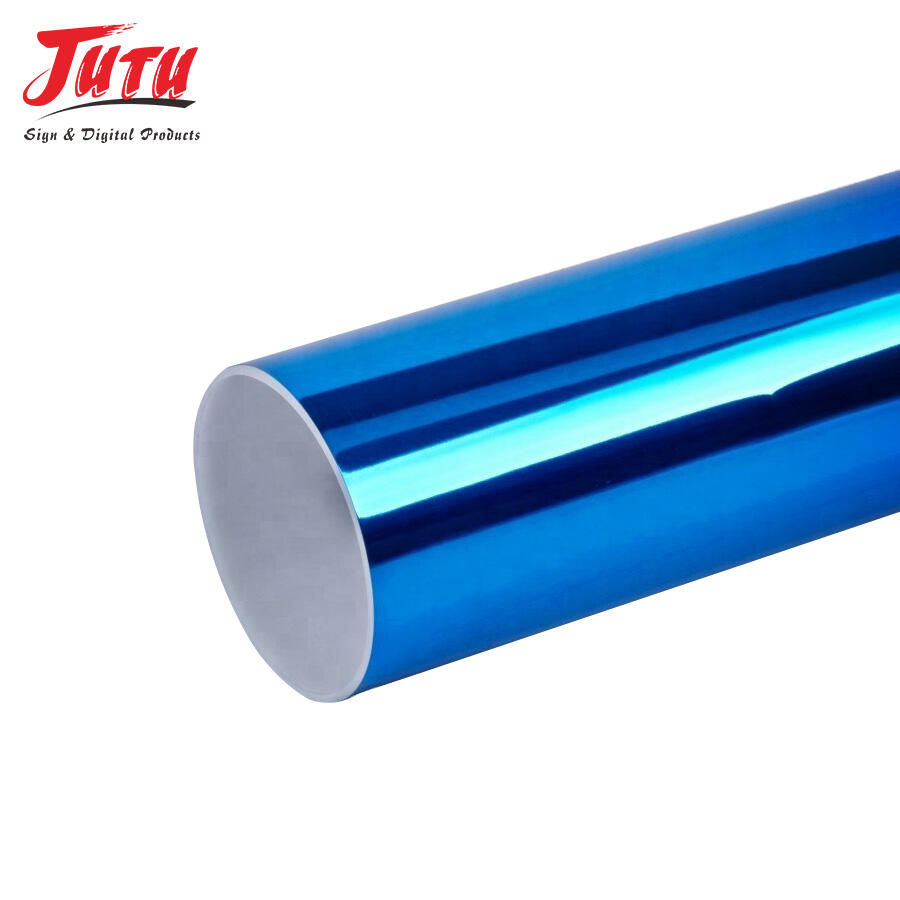

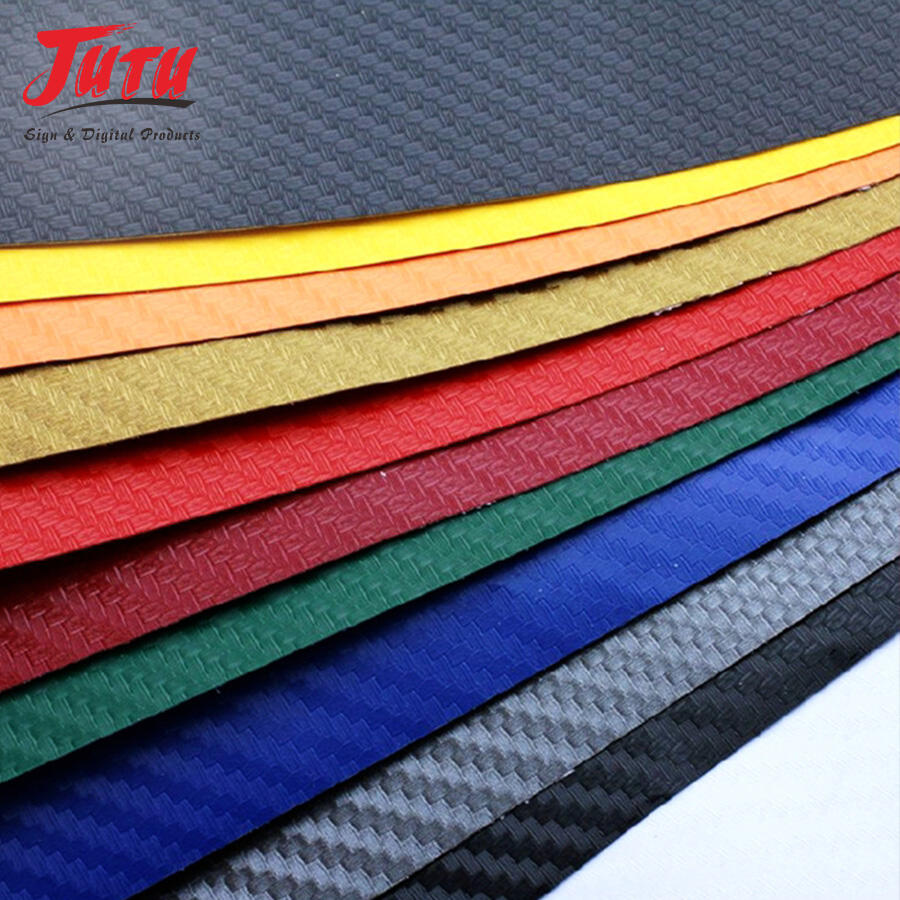

Mastering the art of vinyl installation has become increasingly popular among both DIY enthusiasts and professionals. With the advancement of cold lamination film technology, achieving stunning decorative finishes has never been more accessible. This comprehensive guide will walk you through everything you need to know about installing decorative vinyl like a pro, ensuring beautiful and long-lasting results.

Essential Tools and Materials for Vinyl Installation

Primary Installation Equipment

Before beginning your vinyl installation project, gathering the right tools is crucial for success. You'll need a quality squeegee, precision cutting tools, and most importantly, high-grade cold lamination film. The film serves as a protective layer while ensuring proper adhesion and a professional finish. Make sure to invest in measuring tools, including a tape measure and level, to guarantee precise placement.

Surface Preparation Materials

Proper surface preparation is essential for achieving professional results. Your toolkit should include cleaning solutions specifically designed for vinyl application, lint-free cloths, and surface primers when necessary. When working with cold lamination film, having isopropyl alcohol on hand helps ensure the surface is completely free of oils and contaminants that could compromise adhesion.

Safety and Finishing Equipment

Don't overlook safety equipment and finishing tools. Protective gloves, safety glasses, and a dust mask are essential, especially when working with cold lamination film in enclosed spaces. Include trim tools, edge sealing solutions, and heat guns in your arsenal for achieving clean, professional edges and corners.

Surface Preparation Techniques

Cleaning and Assessment

The success of your vinyl installation largely depends on proper surface preparation. Begin by thoroughly cleaning the target surface with appropriate cleaning solutions. When applying cold lamination film, even microscopic dirt particles can create bubbles or imperfections. Conduct a detailed assessment of the surface, identifying any damage or irregularities that need addressing before installation.

Temperature and Environment Control

Maintaining optimal environmental conditions is crucial for successful vinyl application. The ideal temperature range for working with cold lamination film is between 65-75°F (18-24°C). Ensure proper ventilation and control humidity levels to prevent moisture-related issues during installation. Allow materials to acclimate to room temperature for at least 24 hours before installation.

Professional Installation Methods

Precise Measurement and Planning

Start your installation process with careful measurement and planning. When working with cold lamination film, accurate measurements prevent waste and ensure smooth application. Create detailed layout plans, accounting for patterns, seams, and complex areas. Consider the direction of light and viewing angles to minimize visible seams and optimize the final appearance.

Application Techniques

Master the proper application technique for flawless results. Begin at one edge, carefully peeling back the backing while maintaining tension on the cold lamination film. Use overlapping strokes with your squeegee to prevent air bubbles, working from the center outward. For large surfaces, consider using the hinge method to maintain precise alignment throughout the installation.

Troubleshooting Common Installation Challenges

Dealing with Air Bubbles

Air bubbles are a common challenge when working with cold lamination film. Address small bubbles by gently pushing them toward the nearest edge using your squeegee. For stubborn bubbles, carefully create a tiny puncture with a pin and squeeze the air out, ensuring the adhesive bonds properly afterward. Prevention is key – maintain consistent pressure during application to minimize bubble formation.

Managing Complex Surfaces

Installing vinyl on curved or textured surfaces requires special techniques. When applying cold lamination film to complex surfaces, use heat carefully to make the material more pliable. Work in small sections, ensuring complete adhesion before moving to the next area. For highly detailed areas, consider using specialized application tools designed for reaching into corners and crevices.

Maintenance and Care Guidelines

Daily Care Practices

Proper maintenance extends the life of your vinyl installation. Clean surfaces regularly using mild, non-abrasive cleaners suitable for use with cold lamination film. Avoid harsh chemicals or abrasive cleaning tools that could damage the surface. Address spills promptly to prevent staining or degradation of the adhesive.

Long-term Preservation

Implement strategies for long-term preservation of your vinyl installation. Protect surfaces from direct sunlight when possible, as UV exposure can affect both the vinyl and cold lamination film over time. Regularly inspect for signs of wear or lifting edges, addressing any issues promptly to prevent further damage.

Frequently Asked Questions

What is the optimal temperature for applying cold lamination film?

The ideal temperature range for applying cold lamination film is between 65-75°F (18-24°C). This ensures proper adhesion and workability of the material. Allow both the film and surface to acclimate to room temperature for at least 24 hours before installation.

How long should I wait before cleaning newly installed vinyl?

Wait at least 48 hours after installation before performing any cleaning. This allows the adhesive to fully cure and ensures the cold lamination film has properly bonded to the surface. When cleaning, use only recommended products and gentle techniques.

Can cold lamination film be removed if necessary?

Yes, cold lamination film can be removed if needed. However, the process requires patience and proper technique to avoid damaging the underlying surface. Heat application can help soften the adhesive, making removal easier. Always test in an inconspicuous area first and consider consulting a professional for large-scale removal projects.