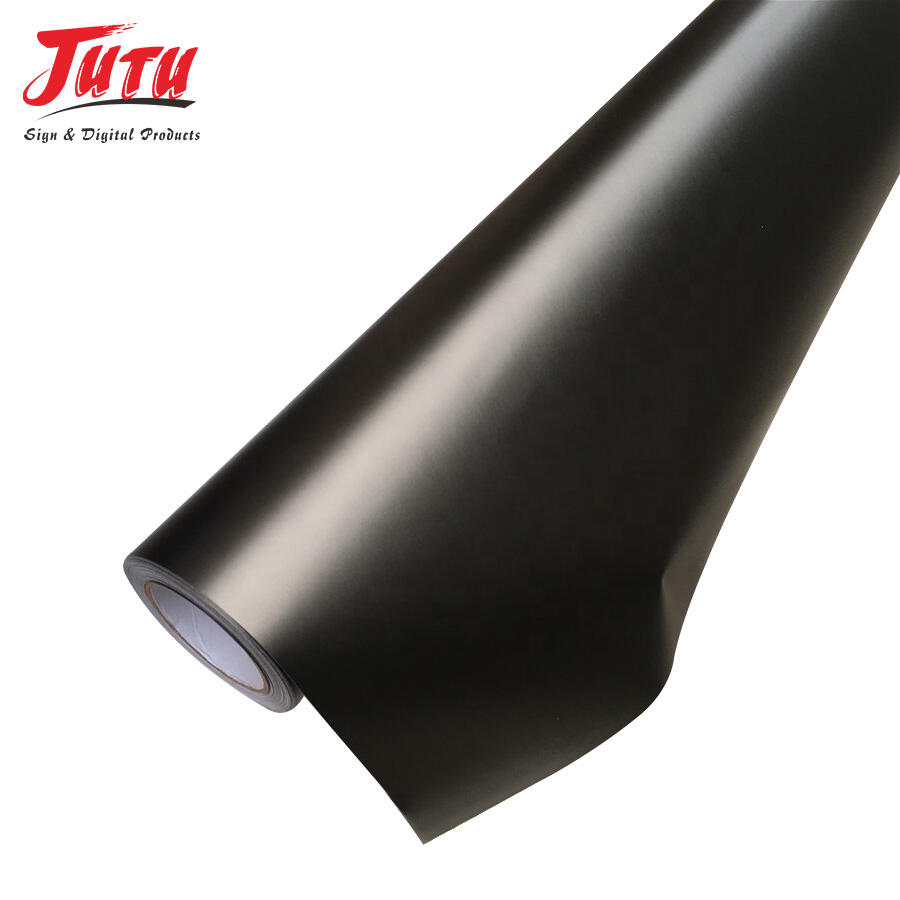

Exceptional Durability and Surface Protection

The camouflage self adhesive vinyl delivers outstanding durability characteristics that protect underlying surfaces while providing long-lasting aesthetic appeal through advanced material engineering and quality manufacturing processes. The multi-layer construction incorporates high-strength vinyl substrates with thickness specifications ranging from 2.5 to 4 mils, providing substantial protection against impact damage, abrasion, and environmental wear. Surface hardness ratings demonstrate resistance to scratching and scuffing that commonly affect painted finishes and decorative laminates during normal use and maintenance activities. The material structure includes reinforcing elements that prevent tearing and propagation of minor damage, ensuring that small punctures or cuts do not compromise the entire installation. Chemical resistance protects against common cleaning agents, automotive fluids, and industrial chemicals that could stain or damage unprotected surfaces. The camouflage self adhesive vinyl functions as an effective barrier against corrosion, particularly valuable for metal substrates exposed to moisture or salt environments. Impact resistance testing confirms the material's ability to absorb and distribute energy from minor collisions and contact damage, preserving both the vinyl surface and underlying substrate integrity. Abrasion resistance measurements exceed industry standards for decorative films, with Taber abraser testing demonstrating minimal wear after thousands of cycles that simulate years of normal handling and cleaning. The material maintains dimensional stability under stress, preventing warping, curling, or distortion that could create entry points for moisture or contaminants. Puncture resistance specifications ensure reliable protection against sharp objects and tools commonly encountered in industrial and automotive environments. The durability characteristics extend to color stability, with accelerated fade testing confirming minimal color change after exposure periods equivalent to decades of outdoor use. Edge sealing properties prevent moisture infiltration along installation perimeters, eliminating potential failure points that compromise long-term performance. The camouflage self adhesive vinyl demonstrates excellent fatigue resistance through repeated flexing cycles that simulate thermal expansion, vibration, and mechanical stress encountered in mobile applications. Protective qualities include prevention of oxidation, staining, and surface degradation that naturally occur on exposed materials over time, effectively extending the useful life of underlying surfaces while maintaining aesthetic appeal.