metallic self adhesive vinyl

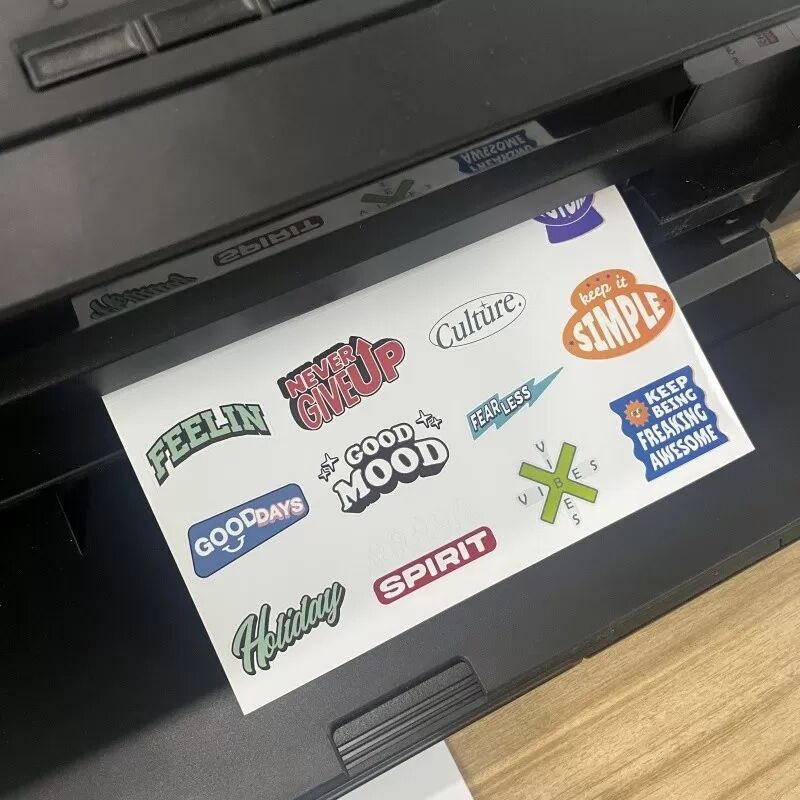

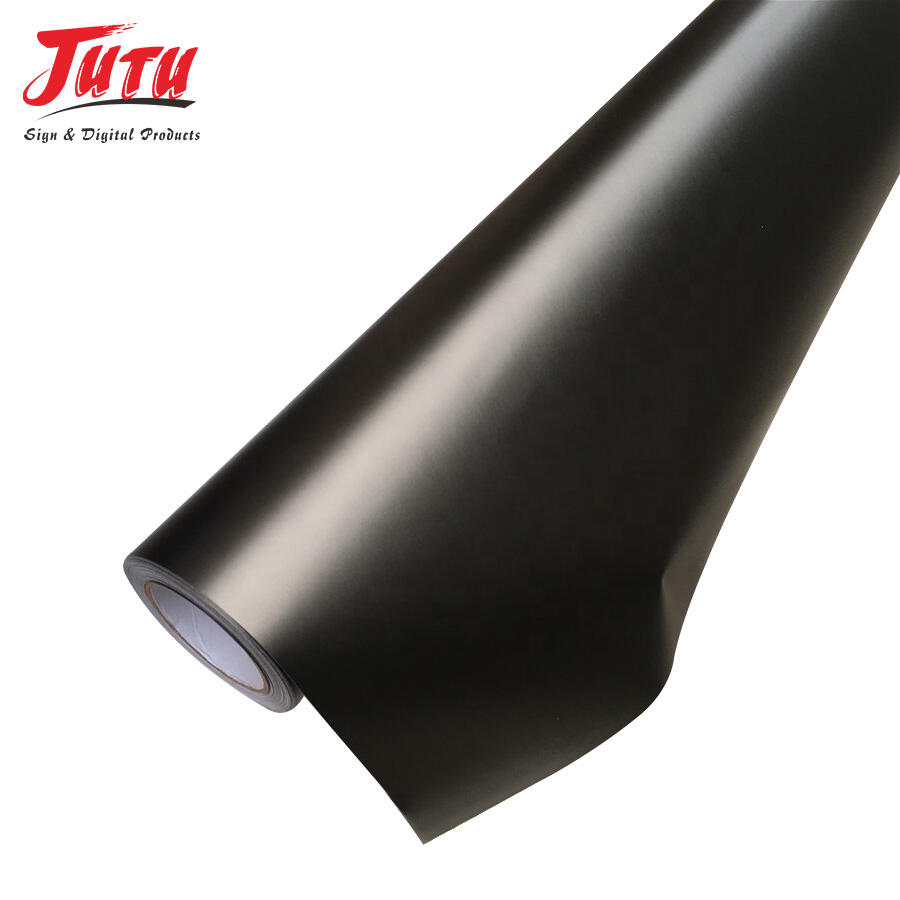

Metallic self adhesive vinyl represents a revolutionary advancement in decorative and functional surface materials, combining the aesthetic appeal of metallic finishes with the convenience of self-adhesive technology. This innovative product consists of a flexible vinyl substrate enhanced with metallic particles or specialized coatings that create stunning reflective surfaces, all backed by a pressure-sensitive adhesive system. The metallic self adhesive vinyl delivers exceptional performance across residential, commercial, and industrial applications, making it an ideal choice for users seeking professional-grade results without complex installation procedures. The core functionality of metallic self adhesive vinyl centers around its ability to transform ordinary surfaces into eye-catching metallic displays. The material features advanced polymer technology that ensures long-lasting adhesion to various substrates including walls, furniture, appliances, signage, and automotive surfaces. The metallic coating provides superior light reflection properties, creating dynamic visual effects that change appearance based on viewing angles and lighting conditions. Technologically, metallic self adhesive vinyl incorporates several sophisticated features that distinguish it from conventional decorative materials. The vinyl base utilizes high-grade PVC or polyurethane compounds engineered for flexibility, durability, and dimensional stability. The metallic layer employs either real metal particles suspended in protective resins or advanced optical films that simulate metallic appearances through interference patterns. The adhesive system features acrylic or rubber-based formulations designed to provide immediate tack while allowing repositioning during initial application phases. Application versatility represents another key aspect of metallic self adhesive vinyl functionality. Interior designers utilize this material for accent walls, cabinet refacing, and decorative panel installations. Automotive enthusiasts employ metallic self adhesive vinyl for vehicle wrapping, trim enhancement, and custom detailing projects. Commercial users implement this product for storefront graphics, exhibition displays, and architectural accent features. The material accommodates both temporary and permanent installations, with removal characteristics varying based on specific adhesive formulations and substrate compatibility.