permanent self adhesive vinyl

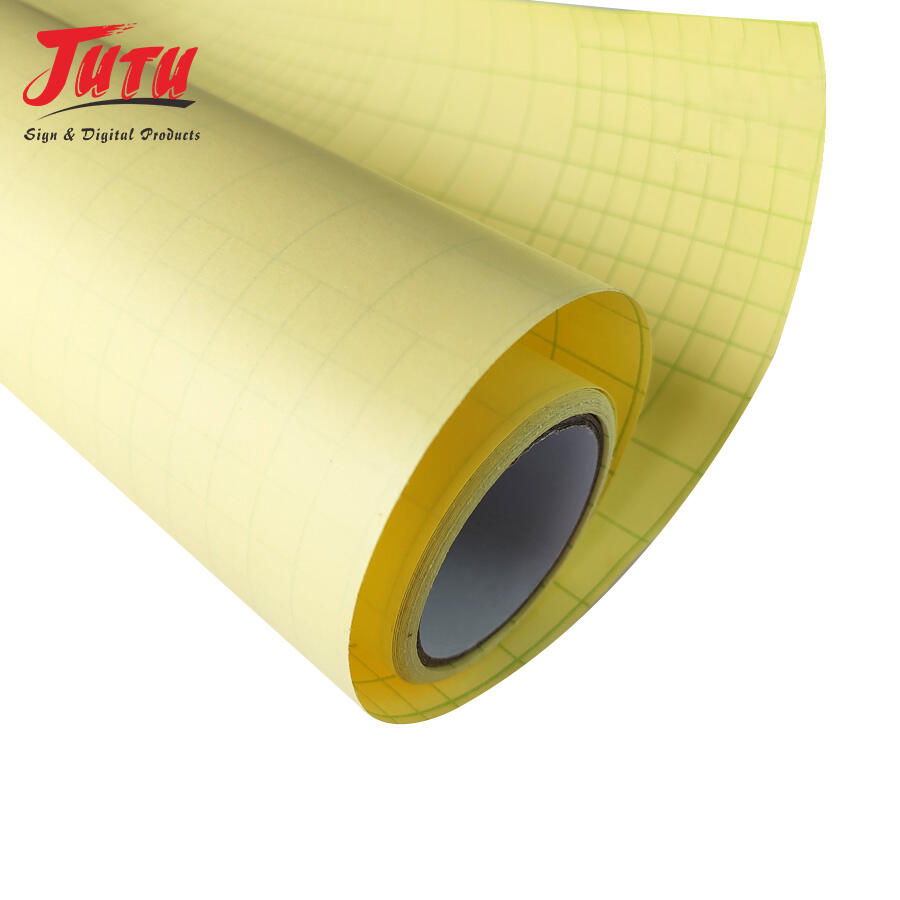

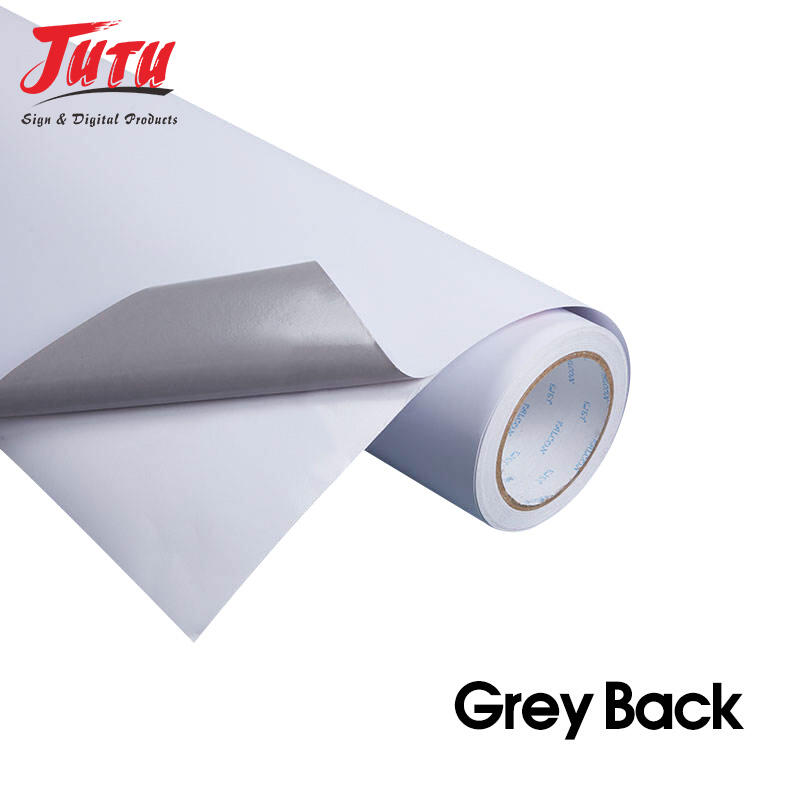

Permanent self adhesive vinyl represents a revolutionary material solution that combines durability with exceptional ease of application across countless surfaces. This advanced vinyl technology features a strong acrylic-based adhesive system that creates lasting bonds with various substrates including metal, plastic, glass, painted surfaces, and textured materials. The permanent self adhesive vinyl incorporates premium-grade vinyl polymers that resist fading, cracking, and peeling under harsh environmental conditions, making it suitable for both indoor and outdoor applications. The material's construction includes multiple layers: a protective topcoat that guards against UV radiation and weathering, a colored vinyl base layer that maintains vibrant appearance, and a specially formulated adhesive backing that ensures secure attachment. Technological innovations in permanent self adhesive vinyl manufacturing have resulted in products that offer superior conformability, allowing the material to follow complex curves and contours without lifting or bubbling. The vinyl's pressure-sensitive adhesive activates upon contact, eliminating the need for additional bonding agents or heat application during installation. Modern permanent self adhesive vinyl formulations incorporate plasticizers that maintain flexibility across temperature ranges from -40°F to 180°F, preventing brittleness in cold conditions and softening in extreme heat. Applications span numerous industries including automotive graphics, architectural signage, fleet vehicle wrapping, retail displays, industrial labeling, safety marking, decorative interior design, and promotional advertising. The material excels in environments requiring long-term visual impact and structural integrity, with many permanent self adhesive vinyl products offering warranties extending 7-10 years for outdoor exposure. Advanced manufacturing processes ensure consistent thickness, uniform adhesive distribution, and precise color matching across production runs, enabling professional results in commercial installations.