Advanced Perforated Technology and Durability

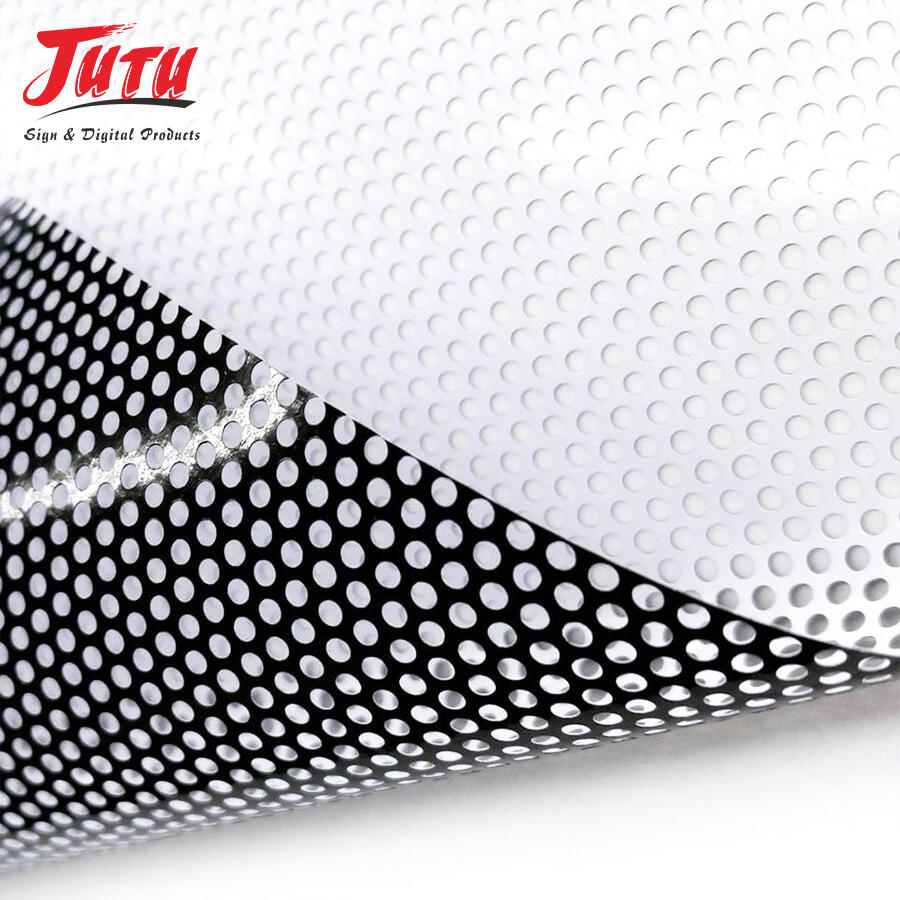

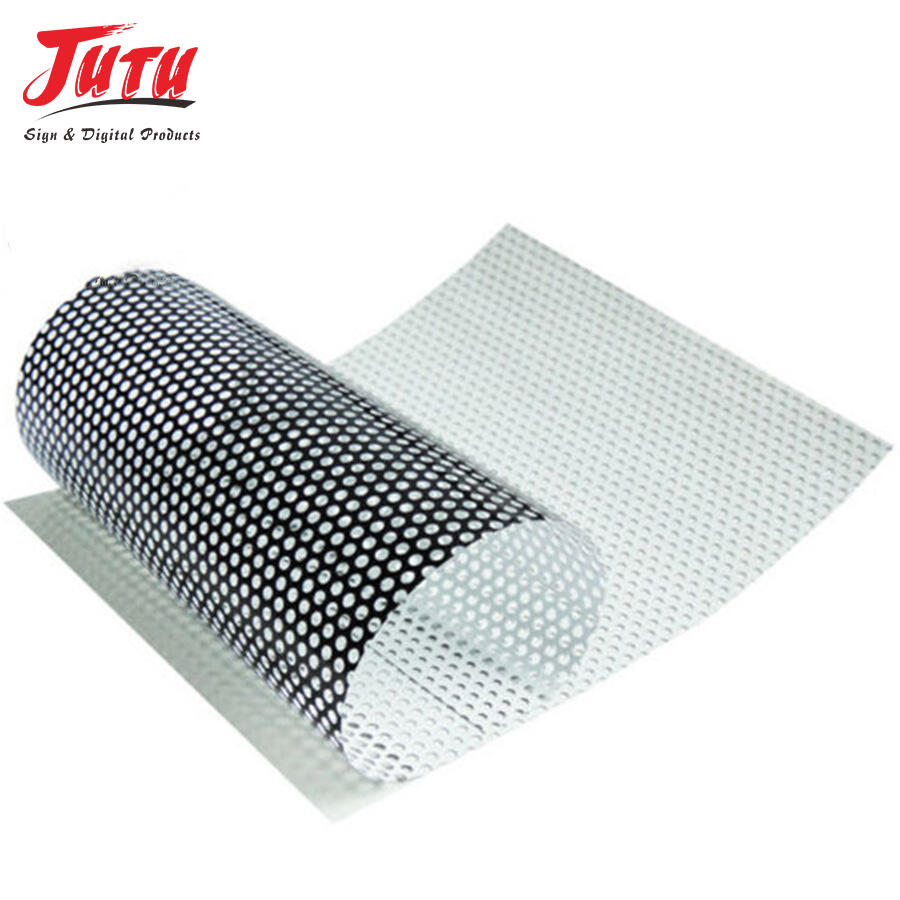

One way vision privacy film incorporates sophisticated perforated technology that represents years of research and development in optical engineering. The manufacturing process involves precise laser cutting or printing techniques that create uniform hole patterns across the film surface. These perforations measure approximately 1.5 millimeters in diameter with specific spacing ratios that optimize the balance between visibility and privacy. The hole pattern density typically ranges from 60 to 70 percent solid material coverage, ensuring adequate privacy while maintaining sufficient light transmission. The film substrate consists of high-quality vinyl materials specifically engineered for outdoor durability and long-term performance. Weather resistance represents a critical aspect of the film's construction, as installations must withstand temperature variations, moisture exposure, ultraviolet radiation, and mechanical stress from wind or vibration. Advanced UV stabilizers incorporated into the film composition prevent degradation, color fading, and material brittleness that commonly affect inferior products. The adhesive system utilizes removable acrylic compounds that create strong bonds with glass surfaces while allowing clean removal when necessary. This technological approach eliminates concerns about permanent installation or potential damage to underlying glass. The printing technology employed in manufacturing one way vision privacy film enables custom graphics, corporate branding, and decorative patterns without compromising the privacy function. Digital printing techniques produce vibrant colors, sharp images, and precise detail reproduction that maintains visual appeal throughout the product's service life. Quality control measures during production ensure consistent perforation patterns, adhesive coverage, and material thickness across entire production runs. Independent testing validates the film's performance characteristics including light transmission rates, privacy effectiveness, adhesive strength, and weather resistance capabilities. Installation simplicity stems from the film's engineered flexibility and conformability to various glass surfaces. Professional installers appreciate the material's forgiving nature during application, as minor imperfections can be corrected without compromising final appearance or performance. The film's thickness provides sufficient durability to resist tearing during installation while remaining thin enough to avoid visibility from interior spaces.