Versatile Processing and Customization Capabilities

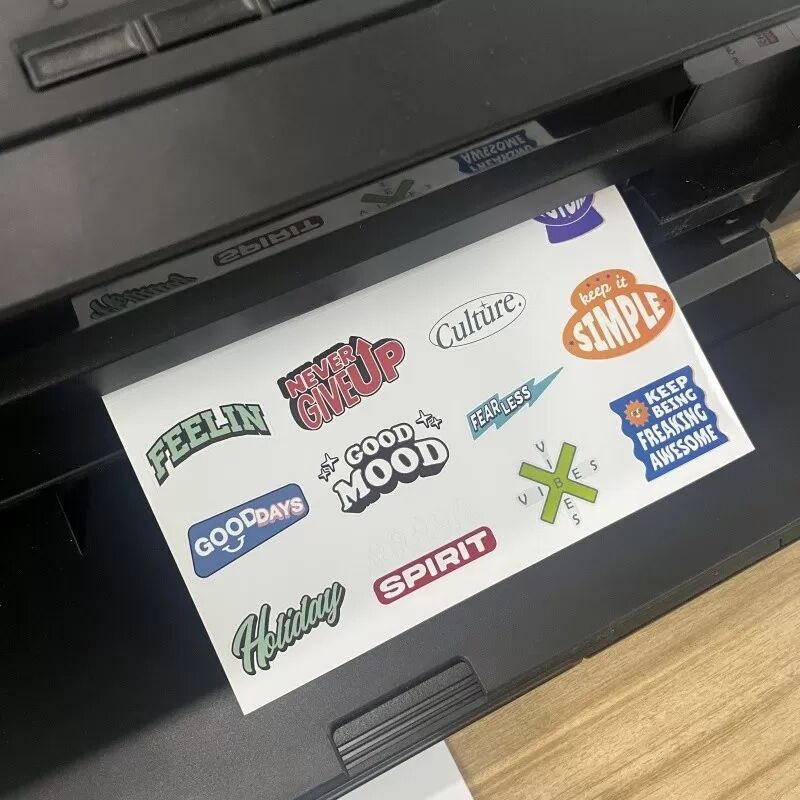

Polyester duck cloth offers unparalleled versatility in processing and customization, enabling manufacturers and end users to create precisely tailored solutions for specific application requirements. The synthetic nature of polyester fibers provides consistent material properties that facilitate predictable processing outcomes, whether through cutting, sewing, heat sealing, or advanced joining techniques. Unlike natural fibers that vary in strength, thickness, and response to processing due to growing conditions and harvesting variables, polyester duck cloth delivers uniform characteristics that ensure repeatable results across production runs. This consistency proves invaluable for manufacturers requiring precise tolerances and predictable performance in their finished products. The fabric's excellent printability opens extensive possibilities for custom graphics, branding, and decorative elements that maintain their appearance throughout the product's service life. Digital printing, screen printing, and heat transfer techniques all work effectively with polyester duck cloth, allowing for vibrant colors, sharp detail reproduction, and durable graphic elements that resist fading, cracking, and peeling. The smooth surface texture of polyester fibers provides an ideal substrate for high-resolution printing, enabling complex designs and fine text that remain legible even after extended outdoor exposure. Lamination capabilities expand the customization potential further, allowing manufacturers to combine polyester duck cloth with specialized films, membranes, or coatings to create composite materials with enhanced properties. These laminated constructions can provide additional waterproofing, chemical resistance, fire retardancy, or other specialized characteristics while maintaining the base strength and durability of the polyester duck cloth substrate. Heat sealing and welding techniques create permanent, waterproof seams that often exceed the strength of the base material, enabling the construction of complex three-dimensional products without mechanical fasteners that could create leak paths or stress concentration points. The fabric responds well to various finishing treatments including water repellent coatings, antimicrobial treatments, and flame retardant applications that can be tailored to meet specific industry standards or performance requirements. Color customization extends beyond surface printing to include solution-dyed options where color is incorporated during the fiber production process, creating fade-resistant materials with uniform color throughout the fiber cross-section. This approach ensures that even if surface wear occurs, the color remains consistent, maintaining product appearance throughout its service life. The processing versatility of polyester duck cloth enables rapid prototyping and short-run customization that would be economically prohibitive with many alternative materials, allowing businesses to respond quickly to market demands and create specialized solutions for niche applications.