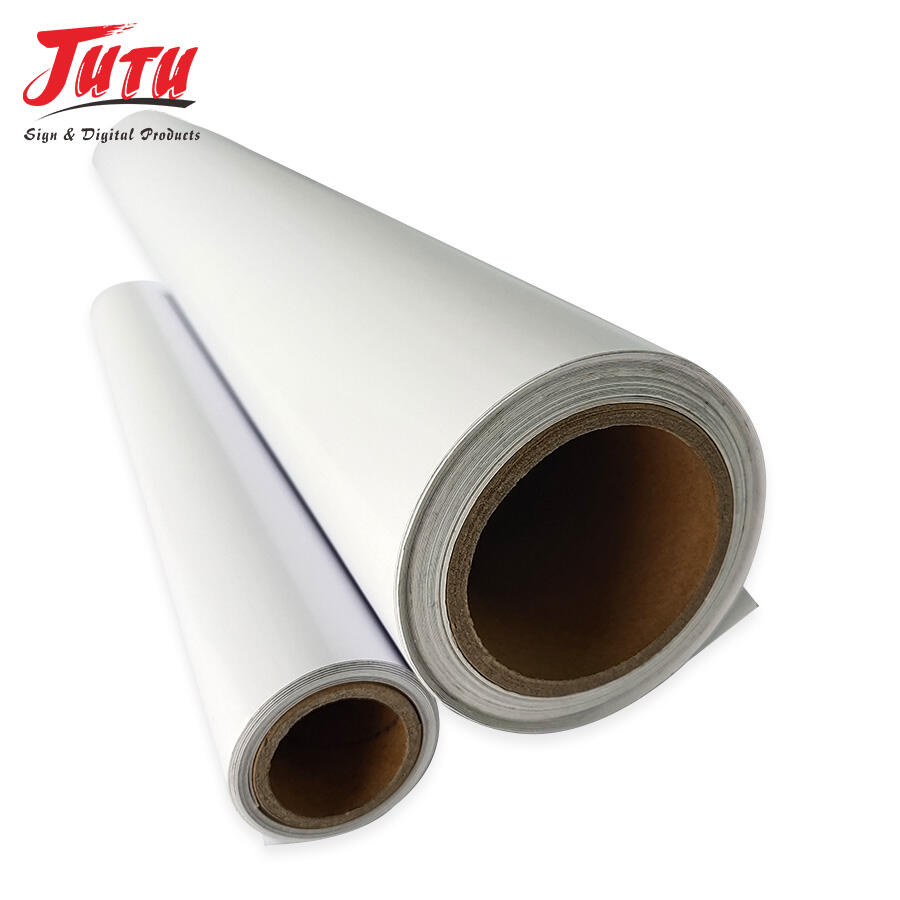

Unlimited Creative Possibilities and Brand Expression

The creative potential of printed self adhesive vinyl is virtually boundless, offering businesses and designers unprecedented freedom to express their brand identity, communicate complex messages, and create visually stunning environments that captivate audiences. Digital printing technology compatible with printed self adhesive vinyl supports full-color reproduction with remarkable accuracy, enabling photographic images, complex illustrations, and gradient effects that were previously impossible with traditional vinyl cutting methods. The color gamut achievable with modern printed self adhesive vinyl rivals that of fine art printing, ensuring that brand colors are reproduced with precision and consistency across all applications. Custom shapes and sizes present no limitations, as printed self adhesive vinyl can be produced in virtually any configuration required by the design, from intricate die-cut details to building-sized graphics that transform entire facades. The material's ability to simulate textures, patterns, and finishes opens new possibilities for interior design and architectural applications, with printed self adhesive vinyl replicating the appearance of wood grain, stone, metal, or fabric at a fraction of the cost of actual materials. Variable data printing capabilities allow each piece of printed self adhesive vinyl to be unique, supporting personalized marketing campaigns, sequential numbering, or location-specific information without additional setup costs. The compatibility of printed self adhesive vinyl with various finishing techniques, including spot UV coating, metallic foils, and textured laminates, creates opportunities for premium appearances that command attention and convey quality. Design flexibility extends to the integration of functional elements such as QR codes, augmented reality triggers, or interactive components that bridge physical and digital marketing strategies. The scalability of printed self adhesive vinyl production accommodates projects ranging from single custom decals to massive fleet graphics, with consistent quality and color matching throughout the entire order. Prototyping capabilities allow designers to test concepts and make adjustments before committing to full production runs, reducing risk and ensuring optimal results. The rapid turnaround times possible with printed self adhesive vinyl enable businesses to respond quickly to market opportunities, seasonal campaigns, or emergency signage needs without compromising quality or breaking budgets.