pvc vinyl heat transfer

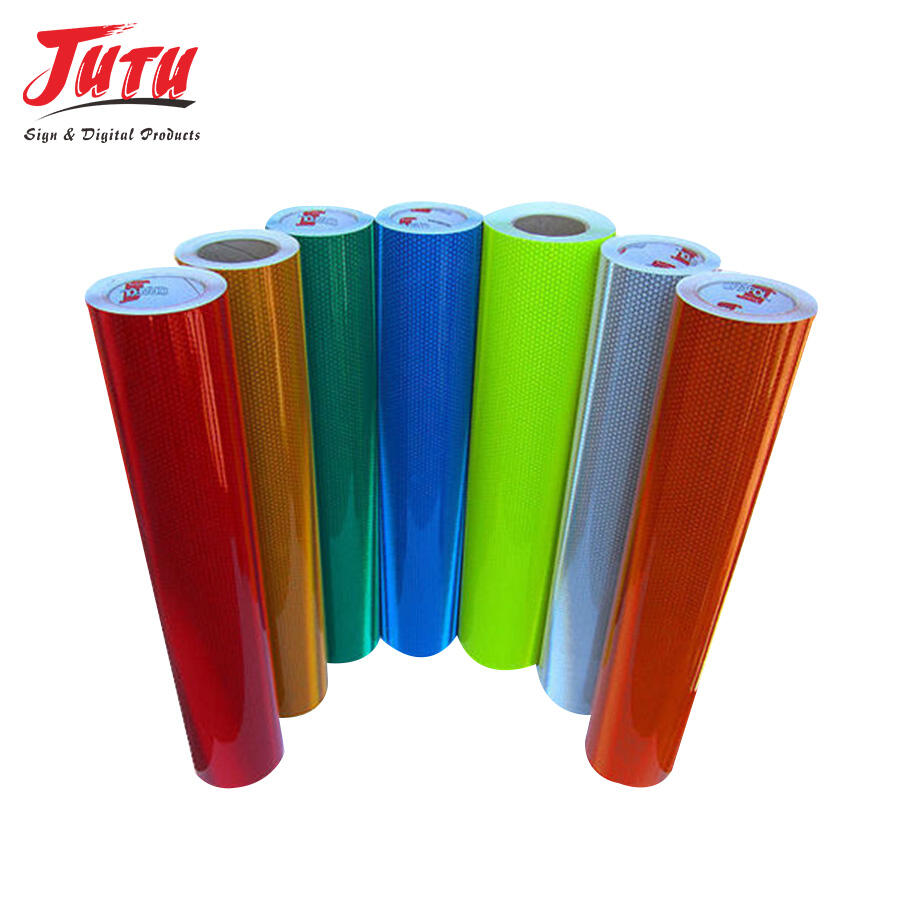

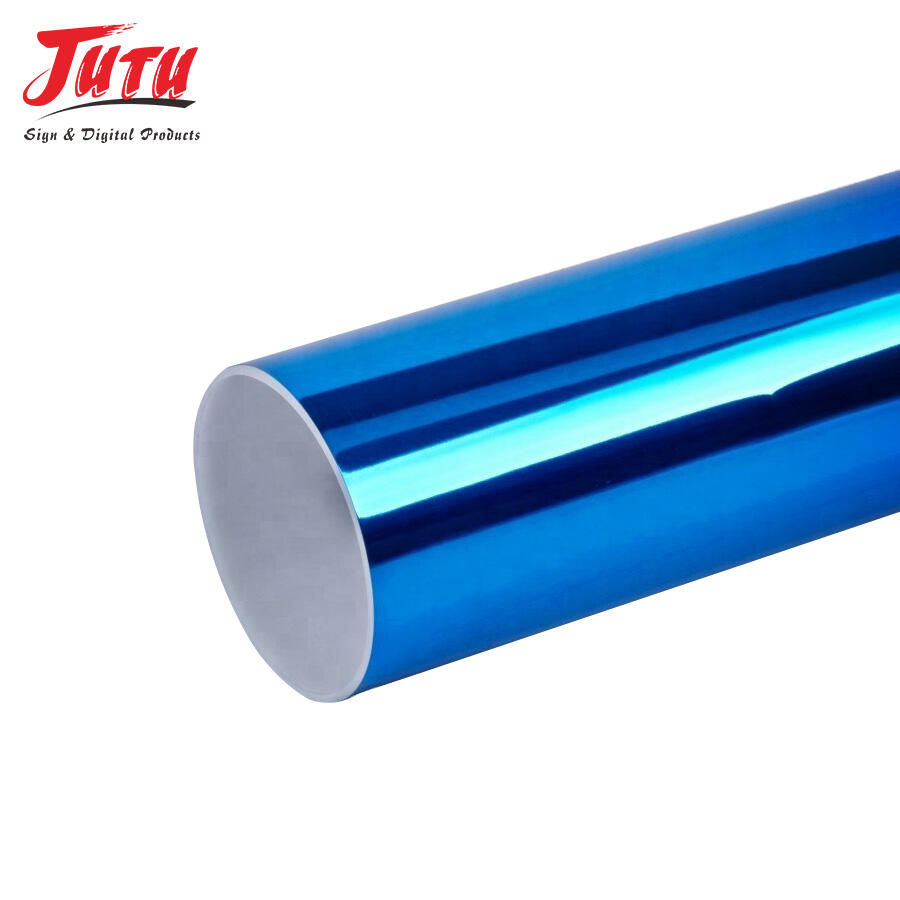

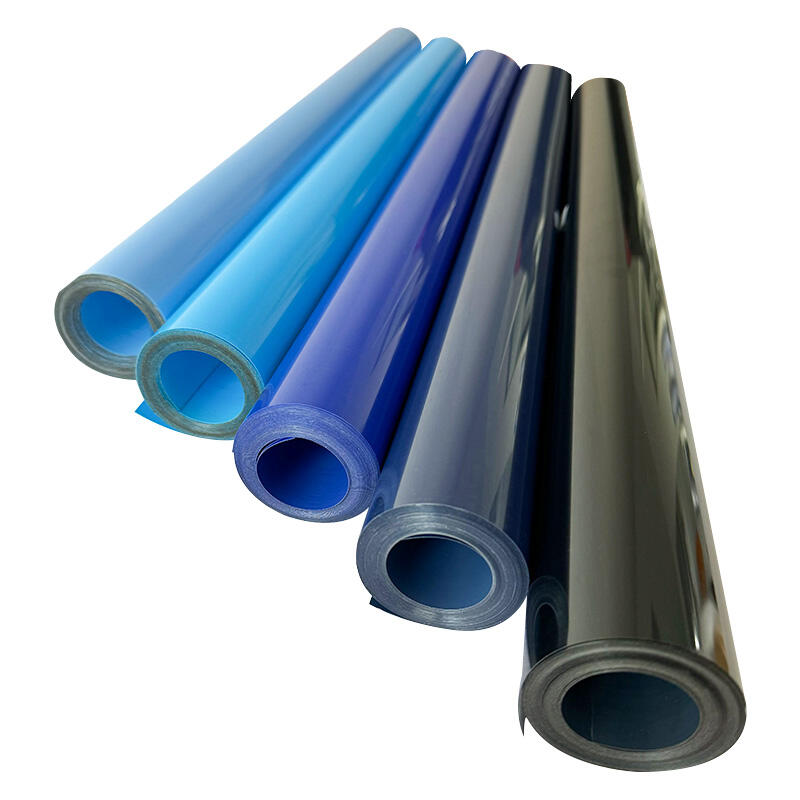

PVC vinyl heat transfer represents a revolutionary method in the world of custom decoration and personalization, offering unparalleled versatility for creating vibrant designs on various fabrics and materials. This innovative technology utilizes specialized polyvinyl chloride materials that respond to controlled heat and pressure, enabling seamless transfer of intricate patterns, logos, and artistic elements onto garments and accessories. The pvc vinyl heat transfer process involves cutting precise designs from colored vinyl sheets using digital plotters or cutting machines, then applying these designs through heat press equipment that activates the adhesive backing. This method has transformed how businesses, crafters, and individuals approach custom decoration projects, providing professional-quality results without requiring extensive technical expertise or expensive printing equipment. The technology behind pvc vinyl heat transfer relies on thermally-activated adhesives that create permanent bonds with fabric fibers when exposed to specific temperature ranges, typically between 300-320 degrees Fahrenheit. The material composition includes multiple layers designed for optimal performance: a carrier sheet for easy handling, the vinyl layer containing pigments and stabilizers, and an adhesive layer engineered for durability and washability. Modern pvc vinyl heat transfer materials incorporate advanced polymer chemistry that ensures color retention, flexibility, and resistance to cracking even after numerous wash cycles. Applications span across numerous industries including sportswear customization, corporate branding, fashion design, promotional merchandise, and personal crafting projects. The versatility of pvc vinyl heat transfer extends to various fabric types including cotton, polyester, blends, and even some synthetic materials, making it an ideal choice for diverse decoration needs. Professional sign shops, screen printing businesses, and small entrepreneurs have embraced this technology for its cost-effectiveness and quick turnaround capabilities, allowing them to serve customers efficiently while maintaining high-quality standards.