Modern businesses require versatile, durable signage solutions that can withstand various environmental conditions while maintaining visual appeal and professional appearance. PVC adhesive vinyl has emerged as the preferred material for countless applications, from storefront displays to vehicle graphics, offering exceptional flexibility and longevity. This specialized material combines advanced polymer chemistry with pressure-sensitive adhesives to deliver superior performance across diverse installation environments.

The construction industry, retail sector, and advertising agencies increasingly rely on high-quality vinyl materials that can adapt to challenging conditions without compromising visual integrity. PVC adhesive vinyl represents a technological advancement that addresses common concerns about material durability, installation complexity, and long-term maintenance requirements. Understanding the unique properties and applications of this material enables businesses to make informed decisions about their signage investments.

Material Properties and Composition

Advanced Polymer Structure

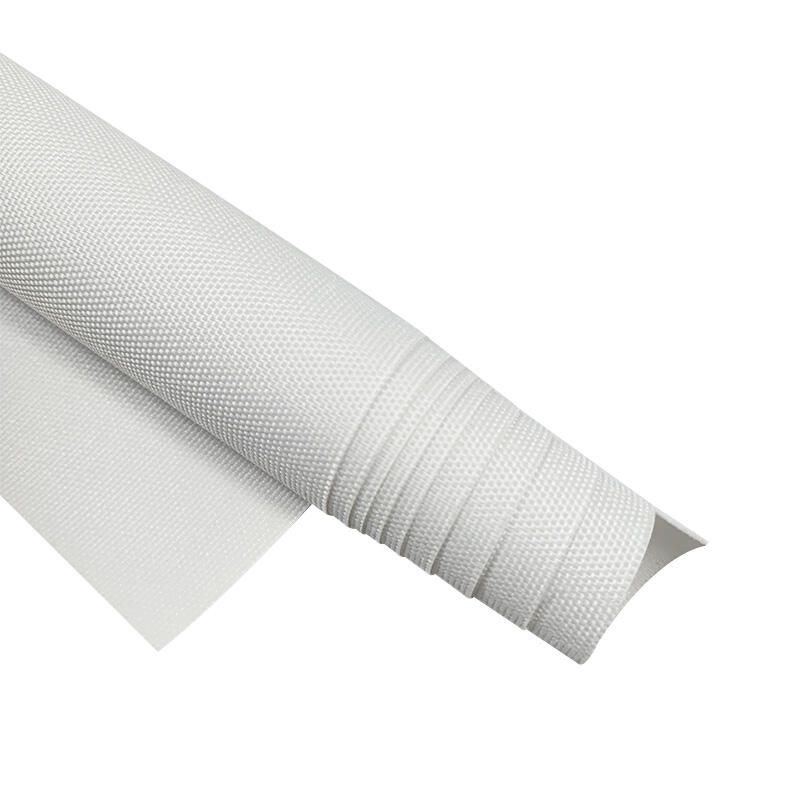

PVC adhesive vinyl features a sophisticated polymer matrix that provides exceptional dimensional stability and resistance to environmental stressors. The material utilizes plasticized polyvinyl chloride compounds that maintain flexibility across temperature ranges while resisting cracking and brittleness. This molecular structure ensures consistent performance whether installed in climate-controlled indoor environments or exposed to outdoor weather variations.

The manufacturing process incorporates UV stabilizers and antioxidants directly into the polymer structure, creating intrinsic protection against degradation from sunlight exposure and atmospheric pollutants. These additives work synergistically to prevent color fading, surface chalking, and mechanical property deterioration that commonly affect inferior vinyl materials. The result is a product that maintains its appearance and functionality throughout extended service life.

Adhesive Technology Integration

Modern PVC adhesive vinyl incorporates pressure-sensitive adhesive systems engineered for specific application requirements. These adhesives utilize acrylic or rubber-based formulations that provide immediate tack while developing full bond strength over time. The adhesive layer includes release characteristics that allow repositioning during installation while ensuring permanent adhesion once properly applied.

Advanced adhesive technology enables the material to conform to textured surfaces, curved substrates, and irregular geometries without losing adhesion or creating air pockets. The adhesive system maintains performance across temperature extremes, humidity variations, and exposure to cleaning chemicals commonly encountered in commercial environments. This versatility makes PVC adhesive vinyl suitable for applications ranging from smooth glass surfaces to corrugated metal panels.

Indoor Application Advantages

Controlled Environment Performance

Interior applications of PVC adhesive vinyl benefit from consistent environmental conditions that maximize material performance and longevity. The controlled temperature and humidity levels found in most commercial buildings create optimal conditions for adhesive curing and long-term bond stability. This environment eliminates concerns about thermal cycling, moisture infiltration, and UV exposure that can challenge outdoor installations.

Indoor applications also allow for more precise installation techniques, including the use of application tools and techniques that might not be practical in outdoor environments. The absence of wind, precipitation, and extreme temperatures enables installers to achieve superior results with reduced risk of contamination or installation defects. PVC adhesive vinyl performs exceptionally well in these conditions, often exceeding manufacturer specifications for adhesion strength and durability.

Aesthetic Versatility and Customization

Interior signage applications demand high visual impact and aesthetic appeal that PVC adhesive vinyl readily provides through advanced printing compatibility and surface finishes. The material accepts various ink systems including solvent, eco-solvent, latex, and UV-cured formulations, enabling vibrant color reproduction and fine detail resolution. This printing versatility supports complex graphics, photographic images, and intricate text elements essential for effective interior communications.

Surface texture options range from high-gloss finishes that enhance color saturation to matte textures that reduce glare and provide sophisticated appearance. Specialty finishes including metallic effects, textured patterns, and dimensional surfaces expand creative possibilities while maintaining the practical benefits of PVC adhesive vinyl construction. These aesthetic options enable designers to create cohesive interior environments that reinforce brand identity and enhance user experience.

Outdoor Durability Characteristics

Weather Resistance Properties

Outdoor applications subject PVC adhesive vinyl to challenging environmental conditions including temperature extremes, UV radiation, precipitation, and atmospheric pollutants. The material's formulation specifically addresses these challenges through stabilizer packages that prevent polymer degradation and maintain mechanical properties throughout extended exposure periods. Laboratory testing confirms performance retention for five to seven years under typical outdoor conditions.

The material demonstrates exceptional resistance to thermal cycling, maintaining dimensional stability and adhesion strength through repeated expansion and contraction cycles. This thermal performance prevents the edge lifting, curling, and adhesive failure commonly experienced with inferior vinyl products. PVC adhesive vinyl also resists moisture absorption that can cause dimensional changes and adhesive degradation in competitive materials.

UV Stability and Color Retention

Ultraviolet radiation represents one of the most significant challenges for outdoor signage materials, causing polymer chain scission and colorant degradation that result in fading, chalking, and mechanical failure. PVC adhesive vinyl incorporates multiple UV protection mechanisms including hindered amine light stabilizers and UV absorbing compounds that intercept harmful radiation before it can damage the polymer matrix.

Color retention performance varies by pigment selection, with high-quality PVC adhesive vinyl maintaining acceptable color stability for extended periods under direct sunlight exposure. Lighter colors and certain metallic finishes demonstrate superior fade resistance compared to deep, saturated colors that naturally absorb more UV energy. Understanding these performance characteristics enables designers to select appropriate color schemes for specific exposure conditions and service life requirements.

Installation Techniques and Best Practices

Surface Preparation Requirements

Successful PVC adhesive vinyl installation begins with proper substrate preparation that ensures optimal adhesive contact and long-term bond performance. Surface cleaning removes contaminants including dust, oils, release agents, and previous adhesive residues that can interfere with adhesion development. Appropriate cleaning solvents vary by substrate material and contamination type, requiring careful selection to avoid surface damage or residue formation.

Surface texture and porosity significantly influence adhesive performance, with smooth, non-porous substrates generally providing superior bond strength compared to rough or highly textured surfaces. PVC adhesive vinyl can accommodate moderate surface irregularities through conformable adhesive systems, but excessive texture may require alternative installation techniques or specialized adhesive formulations. Primer application may be necessary for challenging substrates including certain plastics and powder-coated metals.

Application Methods and Tools

Professional installation of PVC adhesive vinyl requires appropriate tools and techniques that ensure proper adhesive contact while avoiding installation defects such as air entrapment, stretching, or contamination. Squeegee selection depends on material thickness and surface characteristics, with firm squeegees appropriate for smooth surfaces and softer tools recommended for textured substrates or conformable applications.

Temperature control during installation affects both material handling characteristics and adhesive performance. PVC adhesive vinyl becomes more conformable at elevated temperatures, facilitating installation around curves and into recessed areas. However, excessive heat can cause dimensional instability or adhesive flow that compromises long-term performance. Understanding optimal installation temperature ranges ensures successful application across various environmental conditions.

Maintenance and Longevity Considerations

Cleaning and Care Protocols

Proper maintenance extends the service life of PVC adhesive vinyl installations while preserving appearance and functionality. Regular cleaning removes accumulated dirt, pollutants, and biological growth that can degrade surface appearance and potentially affect material properties. Cleaning frequency depends on environmental exposure, with urban installations typically requiring more frequent attention than rural applications due to higher pollutant levels.

Cleaning product selection must balance effectiveness with material compatibility to avoid surface damage or premature wear. Mild detergent solutions generally provide adequate cleaning performance without risking chemical attack of the vinyl surface or printed graphics. Abrasive cleaners and harsh solvents should be avoided as they can cause surface damage that compromises appearance and weather resistance properties.

Performance Monitoring and Replacement Planning

Systematic inspection of PVC adhesive vinyl installations enables proactive maintenance and replacement planning that prevents unexpected failures and maintains professional appearance. Visual inspection should focus on edge adhesion, surface condition, color stability, and overall appearance quality. Early identification of potential issues allows for targeted repairs or replacement before problems become extensive or affect adjacent materials.

Service life expectancy varies based on environmental exposure, installation quality, and material specifications. Indoor applications of high-quality PVC adhesive vinyl typically achieve seven to ten years of satisfactory performance, while outdoor installations may require replacement after five to seven years depending on exposure conditions. Understanding these performance expectations enables accurate budgeting and maintenance scheduling for signage programs.

Cost-Effectiveness and ROI Analysis

Initial Investment Considerations

The cost-effectiveness of PVC adhesive vinyl installations extends beyond initial material costs to include installation labor, maintenance requirements, and replacement frequency. While premium PVC adhesive vinyl products may command higher initial prices compared to economy alternatives, the superior performance and longevity often result in lower total cost of ownership over the installation lifecycle.

Installation efficiency represents another cost factor, with high-quality PVC adhesive vinyl typically easier to handle and install than inferior products. Reduced installation time translates to lower labor costs, while the decreased risk of installation problems reduces callbacks and warranty claims. These factors contribute significantly to project profitability and customer satisfaction.

Long-term Value Proposition

Return on investment analysis must consider the marketing value of professional-appearing signage that maintains its impact throughout the service life. PVC adhesive vinyl installations that retain color stability, adhesion integrity, and overall appearance provide consistent brand representation and communication effectiveness. This sustained performance contrasts with lower-quality alternatives that may degrade rapidly and require premature replacement.

The versatility of PVC adhesive vinyl enables cost-effective solutions for diverse applications within a single project, reducing inventory complexity and installation coordination requirements. This standardization simplifies procurement, reduces training requirements, and enables volume purchasing advantages that further enhance cost-effectiveness. The material's proven performance record also reduces risk and uncertainty associated with specifying newer or unproven alternatives.

FAQ

How long does PVC adhesive vinyl typically last in outdoor applications

High-quality PVC adhesive vinyl installations typically provide five to seven years of satisfactory performance in outdoor environments, depending on exposure conditions and material specifications. Factors including UV intensity, temperature extremes, and atmospheric pollutants influence service life, with installations in harsh environments potentially requiring replacement sooner than those in moderate climates. Proper installation and maintenance can help maximize service life and maintain appearance quality throughout the performance period.

Can PVC adhesive vinyl be removed without damaging the substrate

Most PVC adhesive vinyl products can be removed from appropriate substrates without permanent damage when proper removal techniques are employed. Heat application softens the adhesive and makes removal easier, while specialized removal tools help minimize substrate stress during the process. However, removal success depends on substrate type, installation age, and environmental exposure, with some applications potentially requiring adhesive residue cleanup after vinyl removal.

What surface types are compatible with PVC adhesive vinyl installation

PVC adhesive vinyl adheres successfully to most clean, smooth surfaces including glass, metal, painted surfaces, and many plastic substrates. The material can also conform to moderately textured surfaces and curved geometries, though adhesion performance may vary based on surface characteristics. Challenging substrates such as heavily textured surfaces, certain low-energy plastics, or surfaces with release agents may require special preparation or primer application to ensure adequate bond development.

Does PVC adhesive vinyl require special storage or handling precautions

Proper storage maintains PVC adhesive vinyl quality and ensures successful installation performance. The material should be stored in a clean, dry environment at moderate temperatures, typically between 60-80°F, to prevent adhesive property changes or dimensional instability. Rolls should be stored vertically when possible and protected from direct sunlight, moisture, and contamination. Material should be allowed to acclimate to installation temperature before use, particularly when moving from storage to significantly different environmental conditions.