Wszechstronna kompatybilność aplikacji

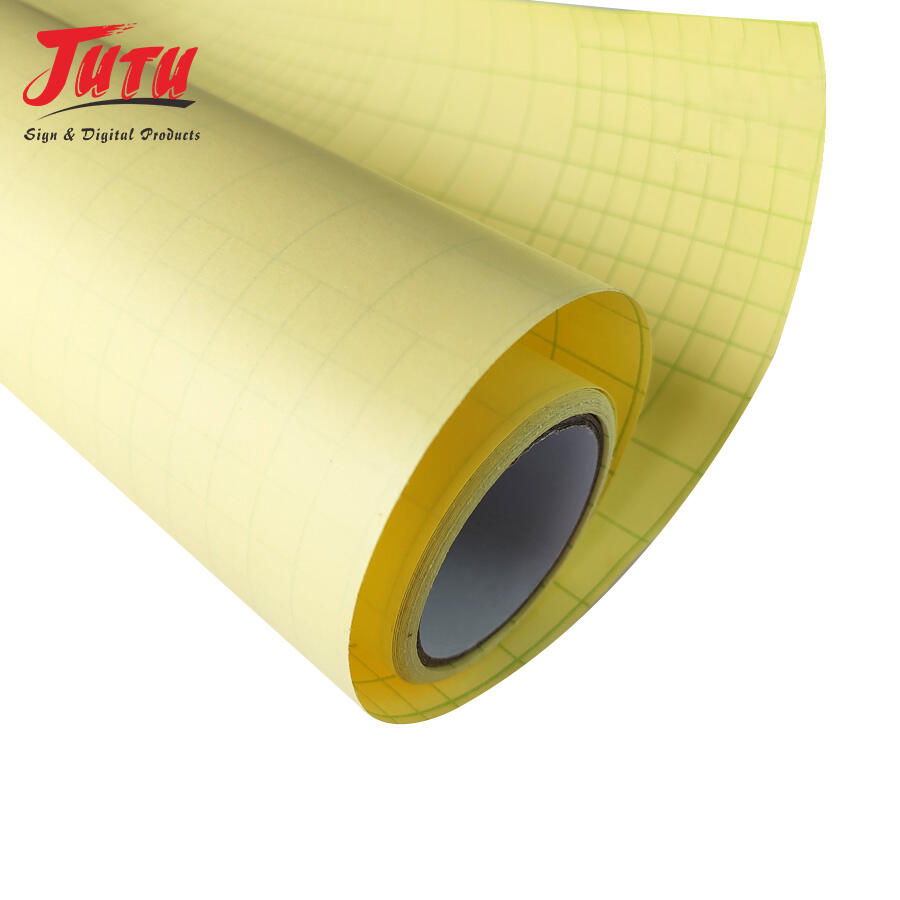

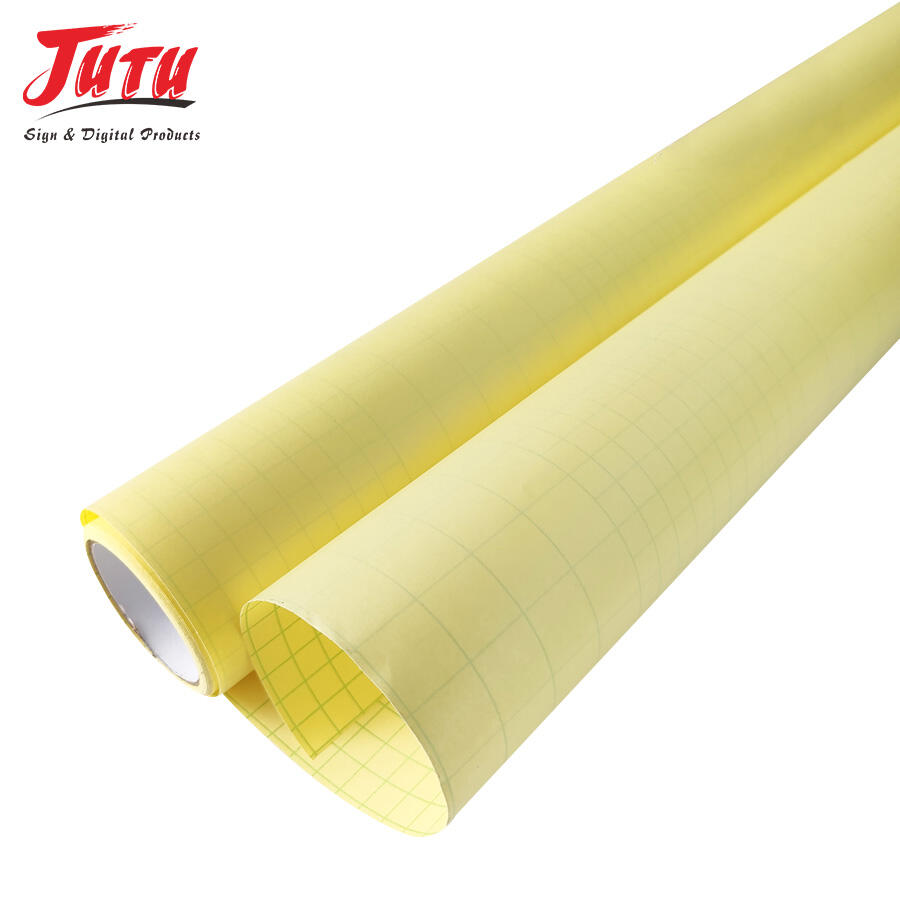

Zimny folia laminacyjna w formie rolki wykazuje wyjątkową wszechstronność w różnych branżach i zastosowaniach, stanowiąc niezwykle cenne rozwiązanie dla firm wymagających elastycznych i niezawodnych możliwości laminowania. Szeroka kompatybilność materiałowa zimnej folii laminacyjnej obejmuje liczne podłoża, takie jak papier, karton, winyl, tkanina, folie metalowe oraz materiały syntetyczne, eliminując potrzebę stosowania wielu specjalistycznych systemów laminujących i upraszczając zarządzanie zapasami. Kompatybilność z drukowaniem cyfrowym stanowi kluczową zaletę – zimna folia laminacyjna działa bezproblemowo ze wszystkimi głównymi technologiami druku, w tym atramentowym, laserowym, termotransferowym i sitodrukiem, nie powodując migracji atramentu, zmiany kolorów ani odkształceń podłoża. Skalowalność zastosowań zimnej folii laminacyjnej obejmuje zarówno małe urządzenia biurkowe służące do laminowania wizytówek i zdjęć, jak również przemysłowe systemy dużego formatu przeznaczone do rysunków architektonicznych, banerów zewnętrznych i grafik pojazdowych. Możliwość obsługi różnych grubości pozwala systemom zimnej folii laminacyjnej na przetwarzanie materiałów o różnej grubości – od cienkiego papieru po grube płyty montażowe – bez konieczności skomplikowanych regulacji czy utraty jakości. Kompatybilność z fakturą powierzchni umożliwia zastosowanie zimnej folii laminacyjnej na gładkich i teksturalnych powierzchniach, połyskłych i matowych wykończeniach, a nawet na lekko nieregularnych podłożach, które mogłyby stanowić wyzwanie dla tradycyjnych metod laminowania. Adaptacja środowiskowa zapewnia, że zimna folia laminacyjna zachowuje swoje parametry eksploatacyjne przy różnym poziomie wilgotności, temperaturze otoczenia oraz warunkach atmosferycznych występujących w różnych regionach geograficznych i wahań sezonowych. Specjalistyczne odmiany zimnej folii laminacyjnej są dostosowane do konkretnych wymagań branżowych, takich jak aplikacje spożywcze, etykietowanie farmaceutyczne, komponenty motoryzacyjne czy środowiska morskie, gdzie standardowe folie laminacyjne mogą zawieść. Opcje wykończenia w asortymencie zimnej folii laminacyjnej obejmują wersje połyskłe, matowe oraz specjalistyczne tekstury, umożliwiając dostosowanie wyglądu końcowego produktu do konkretnych wymagań estetycznych lub funkcjonalnych. Elastyczność prędkości procesu pozwala na wykorzystanie zimnej folii laminacyjnej zarówno w środowiskach produkcji seryjnej, jak i w precyzyjnych zastosowaniach wymagających delikatnego obchodzenia się z materiałem, co czyni ją odpowiednią dla drukarni komercyjnych, działów grafiki wewnętrznej oraz specjalistycznych zakładów produkcyjnych. Warianty archiwalne zimnej folii laminacyjnej spełniają normy konserwacji ważnych dokumentów, fotografii i materiałów historycznych, zapewniając długotrwałą ochronę bez utraty dostępności czy czytelności dla przyszłych pokoleń.