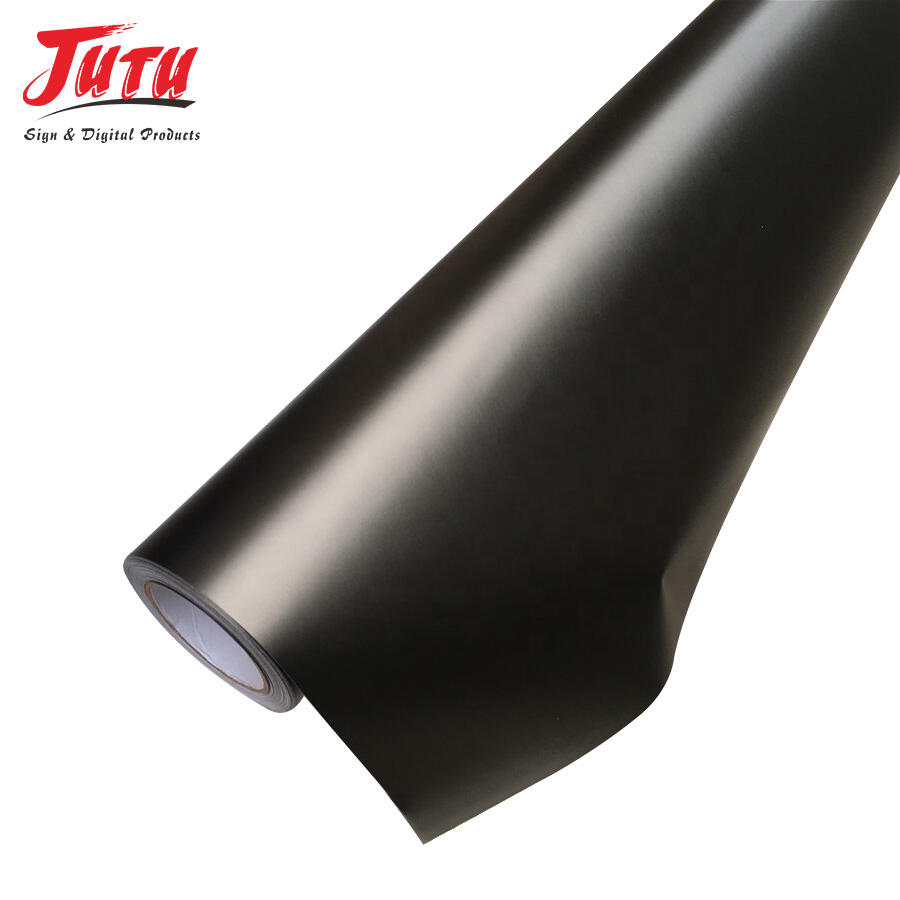

Kosztowna długoterminowa wydajność

Samoprzylepna folia w kolorze granatowym oferuje wyjątkową wartość dzięki przedłużonej trwałości użytkowania i ograniczonym wymaganiom konserwacyjnym, co znacząco obniża całkowite koszty posiadania w porównaniu z alternatywnymi rozwiązaniami powłokowymi. Początkowa inwestycja zapewnia lata niezawodnej pracy bez ponoszenia cyklicznych kosztów związanych z retuszowaniem farbą, nanoszeniem nowych warstw oraz przygotowaniem powierzchni wymaganym do utrzymania wykończenia malowanego. Koszty pracy pozostają minimalne, ponieważ montaż nie wymaga specjalistycznych umiejętności ani sprzętu, umożliwiając organizacjom realizację projektów przez istniejący personel zamiast korzystania z usług zewnętrznych. Materiał eliminuje przestoje związane z pracami malarskimi, które wymagają opróżnienia pomieszczeń, instalacji wentylacji oraz długich okresów wiązania, zakłócających normalny przebieg działalności. Zarządzanie zapasami staje się prostsze, ponieważ samoprzylepna folia w kolorze granatowym charakteryzuje się stabilnym okresem przechowywania i nie wymaga mieszania, rozcieńczania ani specjalnych warunków składowania, jakie mają miejsce w przypadku produktów malarskich ulegających degradacji w czasie. Spójna jakość i wygląd eliminują różnice wynikające z techniki aplikacji, warunków środowiskowych oraz różnic między partiami materiału, które często wpływają na efekt końcowy malowania. Gwarancja zwykle obejmuje dłuższy okres niż tradycyjne gwarancje malarskie, zapewniając dodatkową ochronę przed przedwczesnym uszkodzeniem i kosztami wymiany. Odporność na wypalanie, mazistość i degradację eliminuje stopniowe pogarszanie się wyglądu, które wymusza częste cykle odnowienia powierzchni malowanych. Procedury czyszczenia i konserwacji wymagają jedynie standardowych środków detergentowych i sprzętu, unikając specjalistycznych produktów i technik koniecznych do utrzymania wykończeń malowanych. Wodoszczelna bariera zapobiega uszkodzeniom podłoża, które prowadzą do kosztownych napraw w zastosowaniach, gdzie infiltracja wilgoci powoduje rdzę, gnijenie lub degradację strukturalną. Odporność chemiczna chroni przed przebarwieniami i uszkodzeniami spowodowanymi przypadkowymi wylaniami, które trwale uszkadzają powierzchnie malowane i wymagają natychmiastowego działania. Stabilność wymiarowa zapobiega podnoszeniu się brzegów, pęcherzeniu i odspajaniu, które naruszają zarówno wygląd, jak i funkcję ochronną w produktach niższej jakości. Wysokiej jakości produkty samoprzylepnej folii w kolorze granatowym wykazały swoje skuteczne działanie w wymagających zastosowaniach, gdzie koszty awarii znacznie przekraczają wydatki materiałowe. Przewidywalny okres użytkowania umożliwia dokładne planowanie budżetu i harmonogramu konserwacji, w przeciwieństwie do wykończeń malowanych, które ulegają nieprzewidywalnej degradacji w zależności od oddziaływania środowiska i jakości aplikacji. Korzyści środowiskowe obejmują redukcję emisji lotnych związków organicznych oraz mniejsze generowanie odpadów w porównaniu z powłokami rozpuszczalnikowymi, które wymagają specjalnych procedur utylizacji.