Superior Adhesive Technology for Versatile Installation

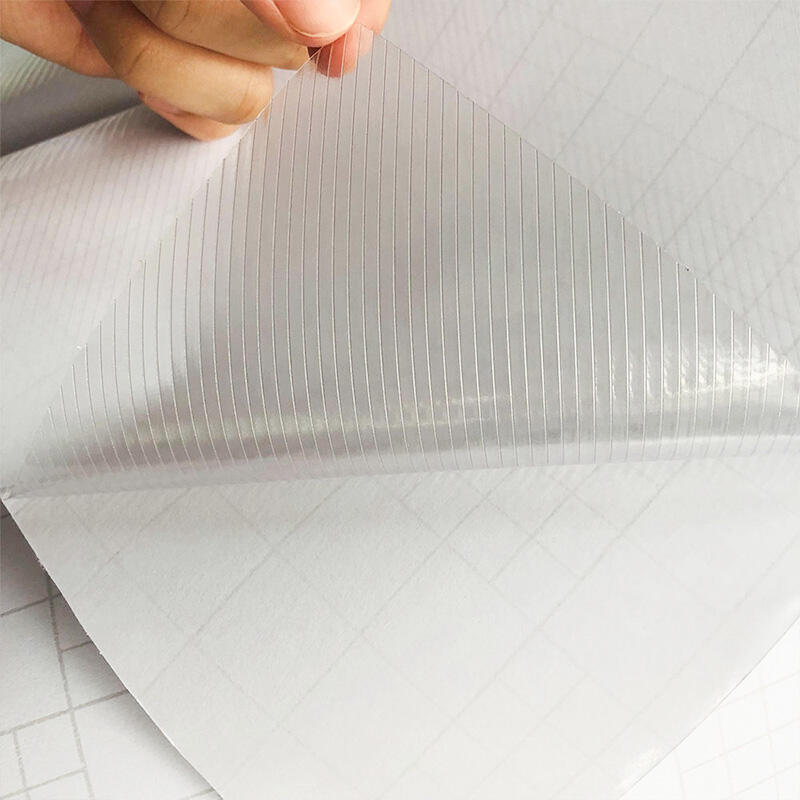

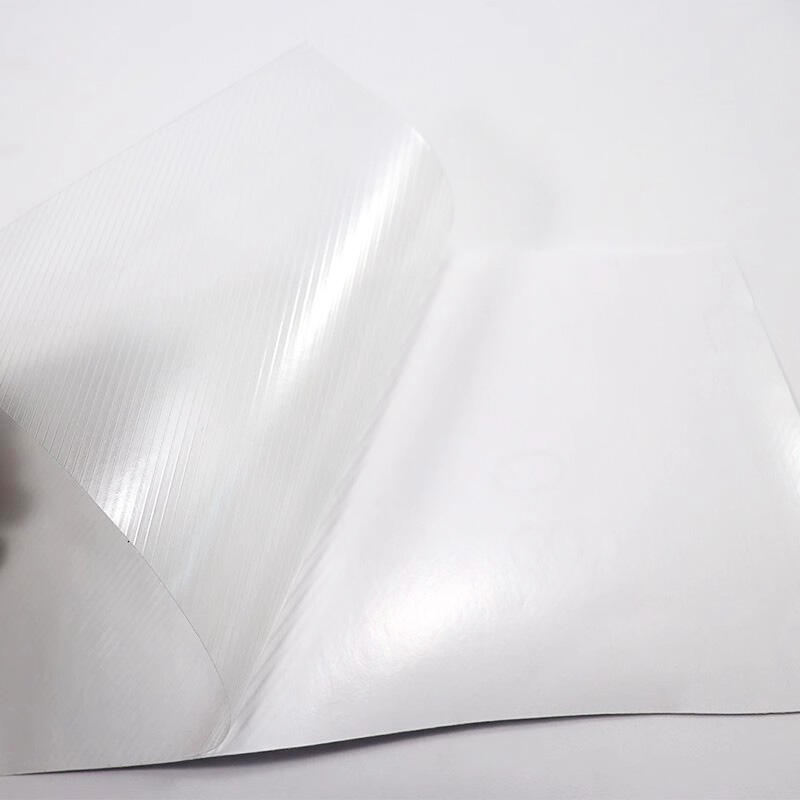

The proprietary adhesive system developed for 3M floor graphics revolutionizes installation processes through innovative bonding chemistry that creates reliable connections across diverse substrate materials while preserving removal flexibility for future renovations or campaign changes. This advanced adhesive technology utilizes pressure-activated compounds that form molecular bonds with concrete, ceramic tile, vinyl flooring, sealed wood surfaces, and other common commercial substrates without requiring primers, etching, or surface preparation beyond standard cleaning procedures. The bonding mechanism provides immediate adhesion upon application while continuing to strengthen over the first 24 hours, ensuring graphics remain securely positioned even in high-traffic environments where foot traffic begins immediately after installation. The engineering behind this adhesive system balances holding power with removability characteristics, allowing graphics to maintain their position throughout extended promotional campaigns while releasing cleanly when removal becomes necessary without damaging underlying floor surfaces or leaving adhesive residue. Temperature resistance built into the adhesive formulation ensures consistent performance across seasonal variations and climate-controlled environments, preventing graphic lifting or edge curling that could compromise appearance or create safety hazards. The versatility of substrate compatibility eliminates the guesswork traditionally associated with floor marking projects, enabling facility managers to specify 3M floor graphics with confidence regardless of existing flooring materials or future renovation plans. Installation efficiency improves dramatically through the pressure-sensitive activation system that eliminates curing times, moisture requirements, or specialized equipment typically needed for permanent floor marking solutions. The adhesive technology accommodates both permanent and temporary applications through controlled release properties that respond to removal techniques, providing businesses with tactical flexibility for seasonal promotions, event-specific messaging, or facility updates without long-term commitments. Quality control testing ensures consistent adhesive performance across manufacturing batches, eliminating variability that could affect installation success or graphic longevity in critical applications. The chemical composition resists degradation from cleaning products commonly used in commercial facilities, maintaining bond integrity throughout regular maintenance cycles without requiring special care procedures or restricted cleaning protocols. Environmental considerations factor into the adhesive development process, with formulations that minimize volatile organic compound emissions and support indoor air quality standards required in healthcare, educational, and corporate environments. This advanced adhesive technology enables creative installations previously impossible with traditional floor marking systems, including curved surfaces, textured substrates, and complex geometric patterns that enhance architectural elements while delivering promotional messages.