Precision Application Technology for Flawless Installation Results

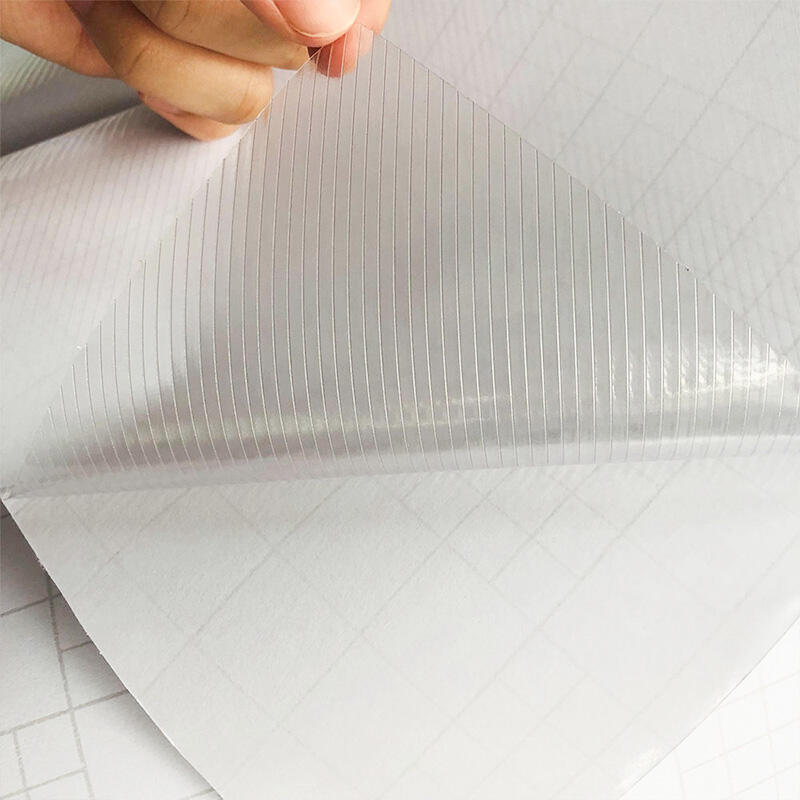

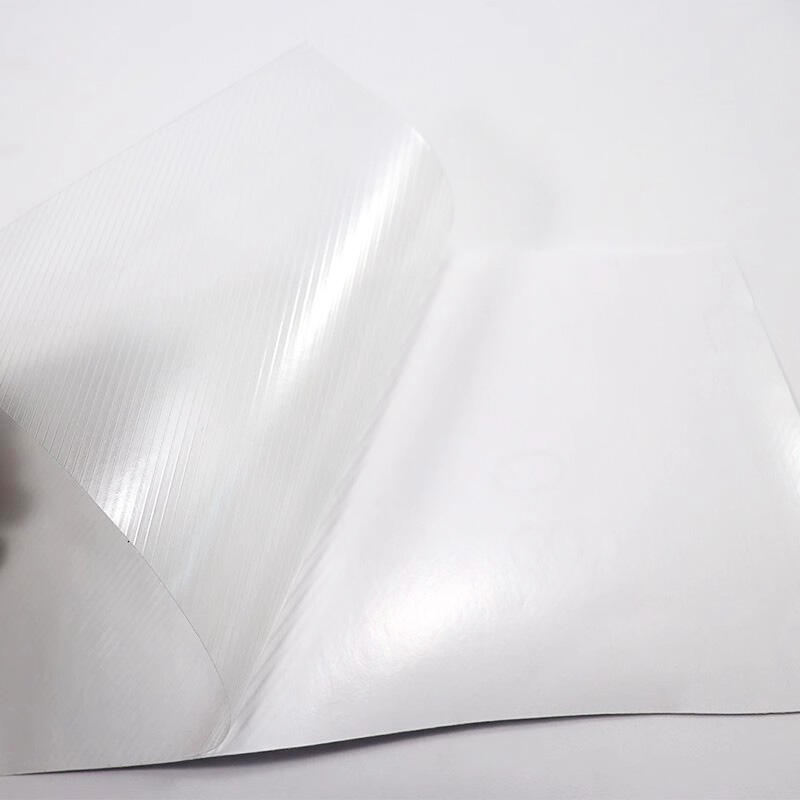

The success of any floor graphics printing project depends critically on precision application technology that ensures seamless installation, optimal adhesion, and professional appearance that reflects positively on your brand image. Professional floor graphics printing installation begins with comprehensive surface preparation protocols that assess substrate compatibility, cleanliness standards, and environmental conditions necessary for optimal adhesive performance. Advanced application tools specifically designed for floor graphics printing include pneumatic rollers, heated squeegees, and edge-sealing devices that eliminate air bubbles, ensure uniform pressure distribution, and create weatherproof seams that prevent moisture infiltration. The installation process utilizes positioning systems that guarantee accurate graphic placement even across expansive floor areas, incorporating laser guides and measurement grids that ensure perfect alignment with architectural features, existing floor patterns, or brand guidelines. Temperature and humidity monitoring during floor graphics printing installation optimizes adhesive activation and prevents application defects that could compromise long-term performance, with professional installers maintaining environmental conditions within specified parameters throughout the process. Bubble elimination techniques employed in professional floor graphics printing installation utilize specialized tools and methodologies that remove trapped air without damaging the graphic surface or compromising adhesive bonds, resulting in smooth, professional installations that enhance rather than detract from the surrounding environment. Edge sealing represents a critical component of floor graphics printing installation, involving precision cutting and sealing techniques that prevent lifting, moisture penetration, and premature wear at graphic boundaries where foot traffic stress concentrates. Quality assurance protocols during floor graphics printing installation include adhesion testing, visual inspection, and performance verification procedures that identify and correct potential issues before they affect the installation's appearance or longevity. The coordination required for large-scale floor graphics printing installations involves project management expertise that minimizes business disruption while ensuring timely completion and optimal results, particularly important in retail environments where installation timing affects customer experience and sales operations. Post-installation documentation provides clients with maintenance guidelines, warranty information, and performance expectations that maximize the return on investment in floor graphics printing technology. Training programs for facility maintenance staff ensure that floor graphics printing installations receive appropriate care and cleaning that preserves appearance and extends service life without voiding manufacturer warranties. The precision achieved through professional floor graphics printing application techniques results in installations that appear integral to the original floor design rather than obvious additions, creating seamless brand experiences that enhance rather than compromise architectural aesthetics.