black sticky back vinyl

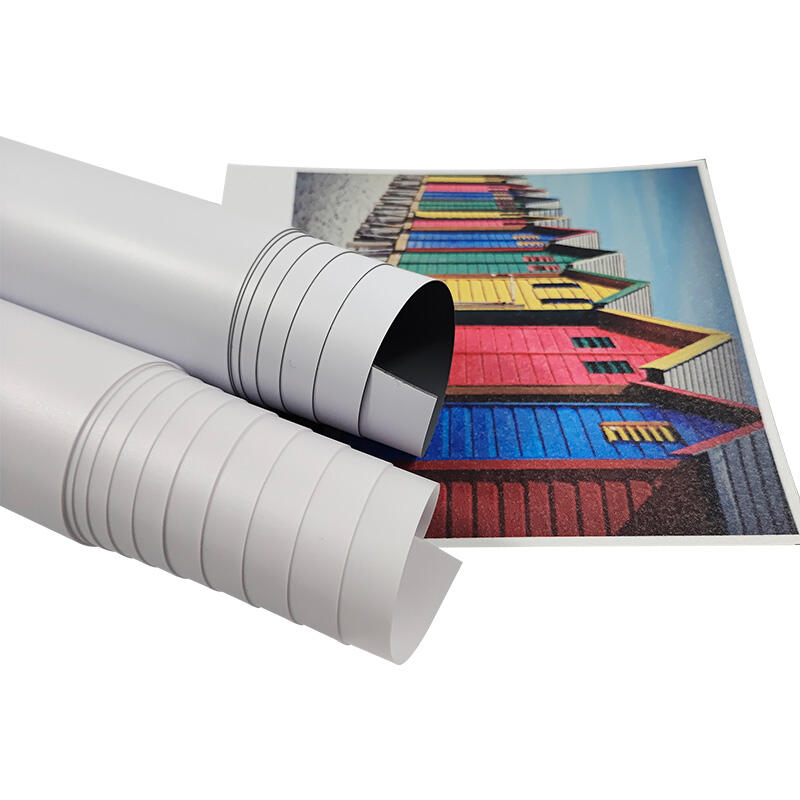

Black sticky back vinyl represents a versatile and practical solution for countless creative, professional, and decorative projects. This self-adhesive material combines the rich aesthetic appeal of deep black coloring with the convenience of peel-and-stick application, making it an ideal choice for both beginners and experienced crafters. The black sticky back vinyl consists of a durable vinyl face material bonded to a pressure-sensitive adhesive backing, protected by a removable liner that ensures clean application every time. Its technological foundation relies on advanced polymer chemistry that creates strong adhesion while maintaining repositionability during initial placement. The material exhibits excellent dimensional stability, meaning it resists shrinking, expanding, or warping under normal environmental conditions. Temperature resistance allows the black sticky back vinyl to perform reliably in various climates, from indoor controlled environments to moderate outdoor applications. The surface texture provides optimal ink receptivity for printing applications while maintaining smooth consistency for cutting operations. Manufacturing processes incorporate UV stabilizers that prevent premature fading and degradation when exposed to sunlight. The adhesive formulation creates permanent bonds with most clean, dry surfaces including glass, metal, plastic, and painted walls. Flexibility characteristics enable the black sticky back vinyl to conform to slightly curved surfaces without cracking or lifting. Applications span multiple industries including signage production, automotive customization, architectural graphics, retail displays, and personal crafting projects. Professional sign makers rely on this material for creating high-contrast lettering and graphics that stand out against lighter backgrounds. Interior designers use black sticky back vinyl for accent walls, furniture makeovers, and decorative elements that add sophistication to modern spaces. The material cuts cleanly with standard craft knives, vinyl plotters, or laser cutting equipment, ensuring precise edges and professional results. Storage stability allows unopened rolls to maintain their properties for extended periods when kept in appropriate conditions.