marine self adhesive vinyl

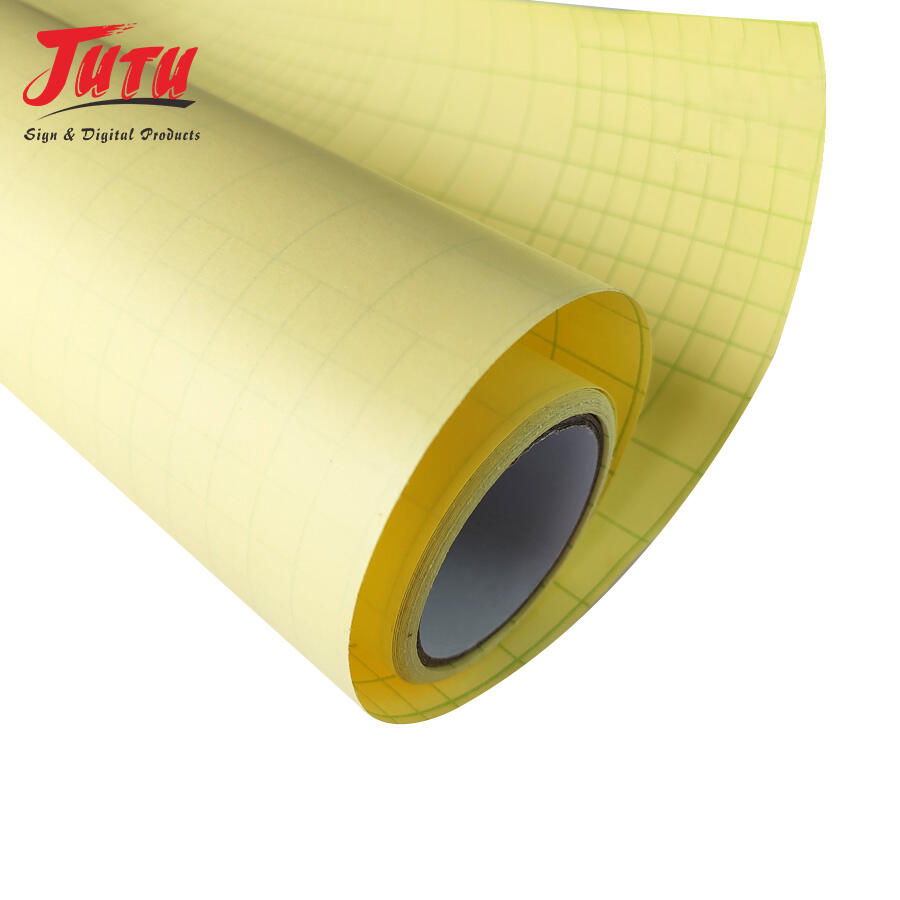

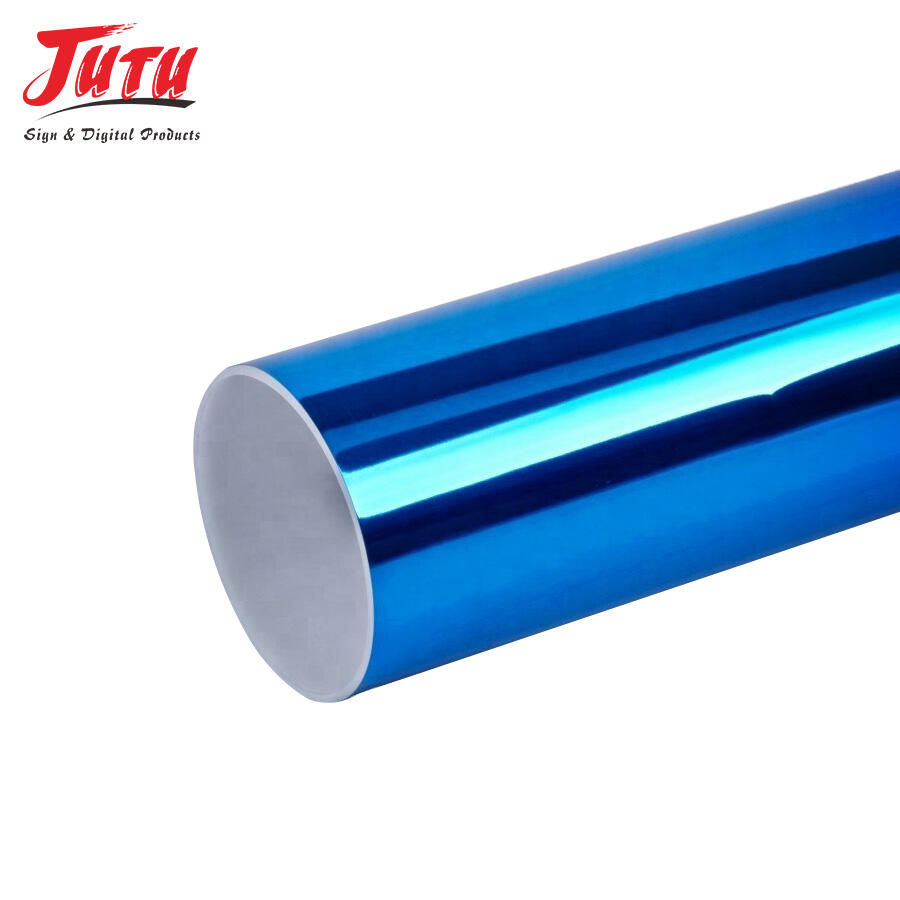

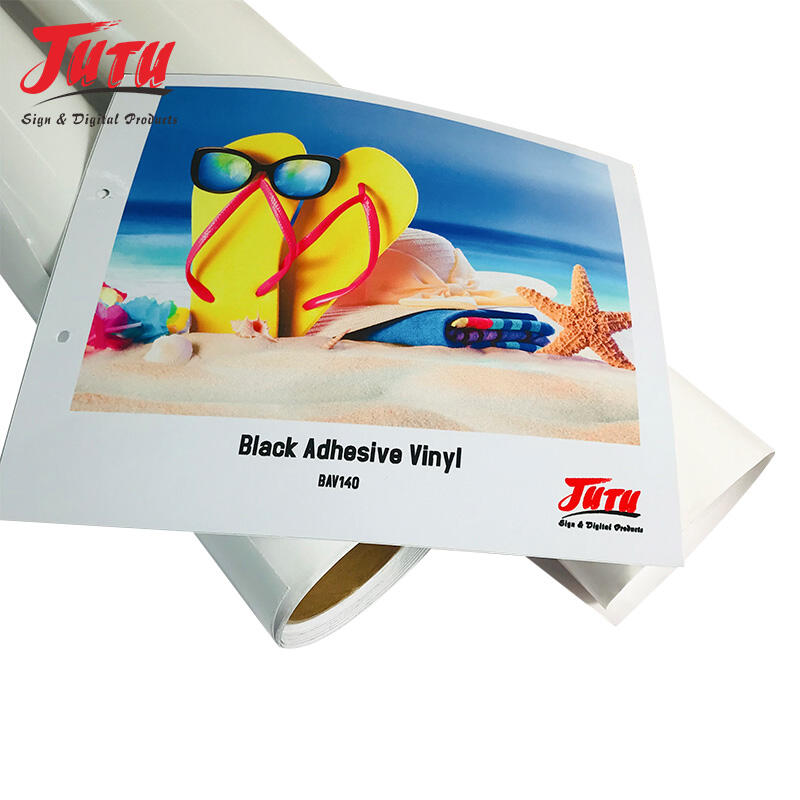

Marine self adhesive vinyl represents a revolutionary breakthrough in boat decoration and protection technology, specifically engineered to withstand the harsh conditions of aquatic environments. This specialized material combines advanced polymer chemistry with pressure-sensitive adhesive systems, creating a durable solution that bonds seamlessly to various marine surfaces including fiberglass, aluminum, wood, and painted substrates. The marine self adhesive vinyl features a unique three-layer construction consisting of a weather-resistant face film, a robust adhesive layer, and a protective release liner that ensures easy application and long-term performance. Unlike conventional marine coatings, this innovative material offers exceptional resistance to saltwater corrosion, UV degradation, and extreme temperature fluctuations that commonly affect watercraft. The vinyl's surface incorporates specialized stabilizers and anti-fade compounds that maintain color vibrancy and structural integrity even after prolonged exposure to intense sunlight and marine elements. Professional marine installers and boat owners increasingly choose marine self adhesive vinyl for its versatility in both decorative and functional applications. The material accommodates complex curves and compound surfaces through its conformable properties, allowing seamless installation around boat hulls, decks, and superstructures. Advanced manufacturing processes ensure consistent thickness and adhesive distribution, eliminating common installation issues like air bubbles and edge lifting. The marine self adhesive vinyl also features enhanced chemical resistance against fuel spills, cleaning solvents, and marine growth treatments, making it ideal for commercial and recreational vessels. Its removable characteristics enable easy updates and modifications without damaging underlying surfaces, providing cost-effective maintenance solutions for fleet operators and individual boat owners seeking professional-grade protection and aesthetics.