Versatile Application Compatibility

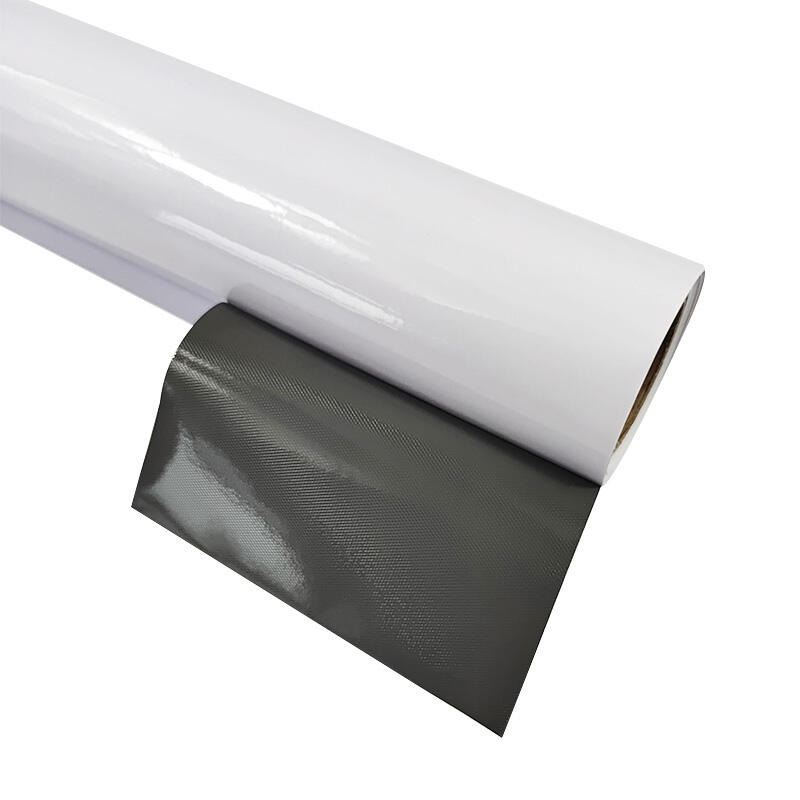

The versatile application compatibility of intercoat digital vinyl represents a comprehensive solution designed to meet diverse market demands across multiple industries and installation environments. This exceptional versatility stems from extensive research and development efforts that identified key performance requirements across various application sectors, resulting in a material engineered to excel in both indoor and outdoor environments. The compatibility extends to surface preparation requirements, as intercoat digital vinyl adheres effectively to properly prepared substrates including aluminum, steel, glass, acrylic, and various composite materials commonly encountered in commercial signage applications. Temperature performance characteristics enable successful installation and long-term service across climate zones ranging from arctic conditions to desert environments, maintaining adhesive integrity and graphic quality despite extreme temperature fluctuations. The material's chemical formulation provides resistance to common cleaning agents, automotive fluids, and industrial chemicals, making it suitable for applications in manufacturing facilities, transportation hubs, and retail environments where exposure to various substances is unavoidable. Installation flexibility accommodates both wet and dry application techniques, allowing installers to select the most appropriate method based on environmental conditions and project requirements. The compatibility extends to removal characteristics, as the material can be formulated with different adhesive systems ranging from removable options for temporary applications to permanent bonding for long-term installations. Surface texture compatibility enables successful application on both smooth and moderately textured substrates, expanding installation possibilities beyond traditional flat surfaces. Print compatibility encompasses all major digital printing technologies including wide-format solvent, eco-solvent, latex, and UV-curable systems, allowing print service providers to integrate intercoat digital vinyl into existing production workflows without equipment modifications. The versatility includes compatibility with various finishing techniques such as lamination, die-cutting, and thermal forming, enabling complex fabrication processes required for dimensional signage and specialized graphics. Quality control standards ensure consistent performance across all compatible applications, providing users with confidence that material characteristics will remain predictable regardless of the specific application requirements. This comprehensive compatibility reduces inventory requirements for businesses serving diverse markets, as a single material can address multiple application needs while maintaining optimal performance standards across all use cases.