vinyl digital printing

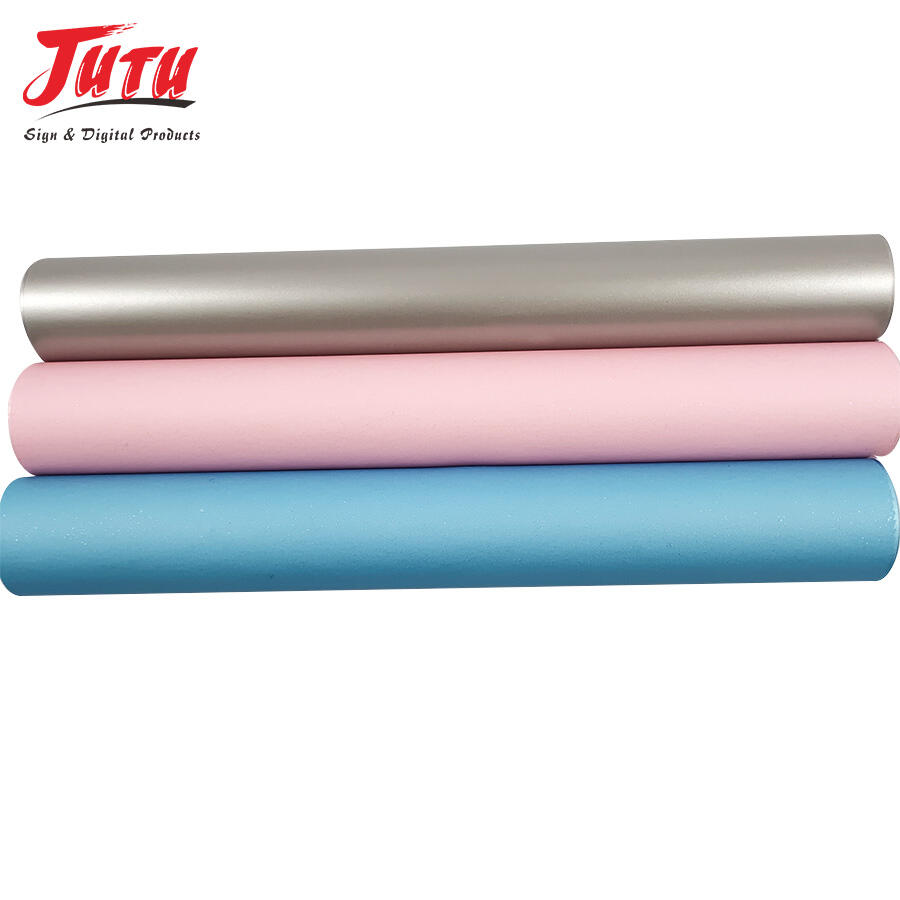

Vinyl digital printing represents a revolutionary advancement in modern graphic production, combining cutting-edge digital technology with versatile vinyl materials to deliver exceptional visual solutions. This innovative printing method utilizes sophisticated inkjet technology to directly transfer high-resolution images, text, and graphics onto various vinyl substrates with remarkable precision and clarity. The process employs specialized UV-resistant inks that bond seamlessly with vinyl surfaces, creating durable, weather-resistant prints that maintain their vibrancy over extended periods. Vinyl digital printing operates through computerized systems that can reproduce millions of colors, ensuring accurate color matching and consistent quality across large production runs. The technology supports multiple vinyl types, including cast vinyl for complex curves, calendered vinyl for flat applications, and specialty materials like reflective or textured surfaces. Modern vinyl digital printing equipment features advanced print head technology that delivers resolutions up to 1440 dpi, producing sharp details and smooth gradients that rival traditional printing methods. The digital workflow eliminates the need for film separations or plates, enabling rapid turnaround times and cost-effective short runs. Applications span numerous industries, from automotive wraps and architectural graphics to retail signage and promotional materials. The versatility of vinyl digital printing extends to both indoor and outdoor applications, with prints capable of withstanding harsh environmental conditions including UV exposure, temperature fluctuations, and moisture. Industrial applications include fleet graphics, building wraps, trade show displays, and safety signage, while commercial uses encompass storefront graphics, window displays, vehicle advertising, and branded merchandise. The technology accommodates various finishing options, including lamination for enhanced protection, contour cutting for precise shapes, and special effects like metallic or holographic finishes, making vinyl digital printing an indispensable tool for modern visual communication strategies.