Unmatched Design Flexibility and Customization Options

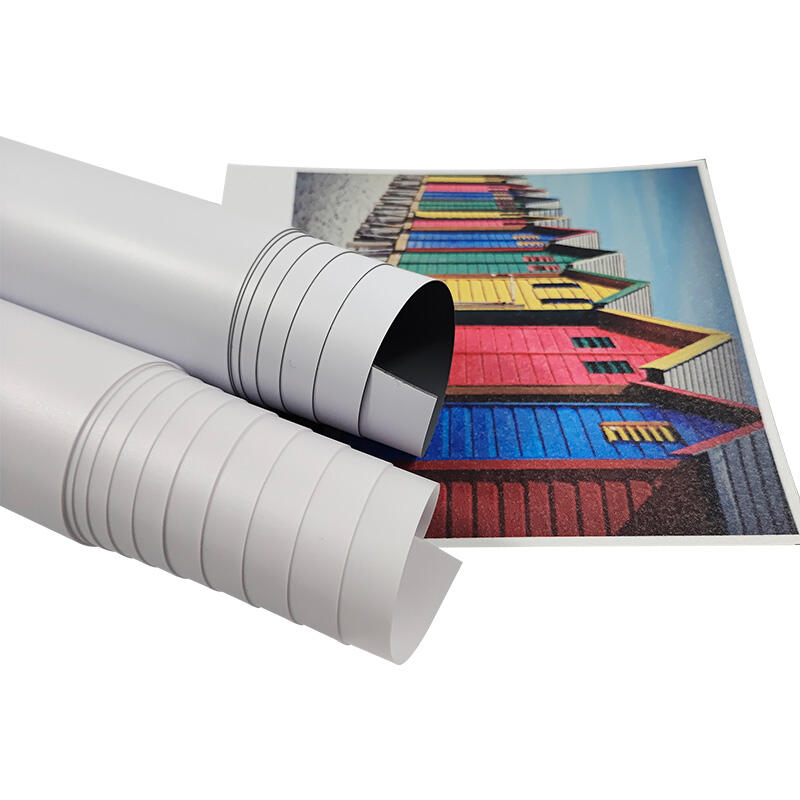

Digitally printed vinyl offers unprecedented design flexibility and customization capabilities that empower creative professionals to realize their most ambitious visual concepts without technical limitations. The digital printing process eliminates traditional constraints associated with screen printing, such as color separations, screen tensions, and setup requirements that often compromise design integrity. Variable data printing capabilities enable mass customization, allowing unique personalization for individual recipients while maintaining production efficiency. Sequential numbering, personalized text, and individual graphics can be incorporated seamlessly within single production runs. Complex design elements including photographic backgrounds, intricate illustrations, and detailed logos reproduce accurately without simplification or color reduction typically required by conventional methods. Unlimited color options provide designers with complete creative freedom, supporting millions of color combinations through advanced color mixing systems. Gradient effects, shadow details, and transparency effects translate directly from digital files to printed graphics without modification or compromise. Small quantity production becomes economically viable, encouraging experimentation with new designs, limited edition releases, and prototype development. Design revisions can be implemented quickly without additional setup costs, enabling iterative design processes and client collaboration. File format compatibility encompasses industry-standard formats including Adobe Creative Suite files, ensuring seamless workflow integration with existing design processes. Proof systems provide accurate preview capabilities, allowing design verification before final production and reducing revision cycles. Custom sizing accommodates virtually any dimension requirements without affecting print quality or production feasibility. Shape cutting capabilities enable custom contours, decorative edges, and precision fitting for specific applications. Multiple finish options including gloss, matte, and textured surfaces provide additional design possibilities and tactile experiences. Spot colors and Pantone matching ensure brand consistency and accurate color reproduction for corporate identity applications. Metallic effects, fluorescent colors, and specialty inks expand creative possibilities beyond conventional printing limitations. The digital workflow supports rapid prototyping, enabling quick turnaround for design concepts and client presentations. Design archives remain permanently accessible for reprinting, modifications, or future reference, providing long-term value and consistency for ongoing projects.