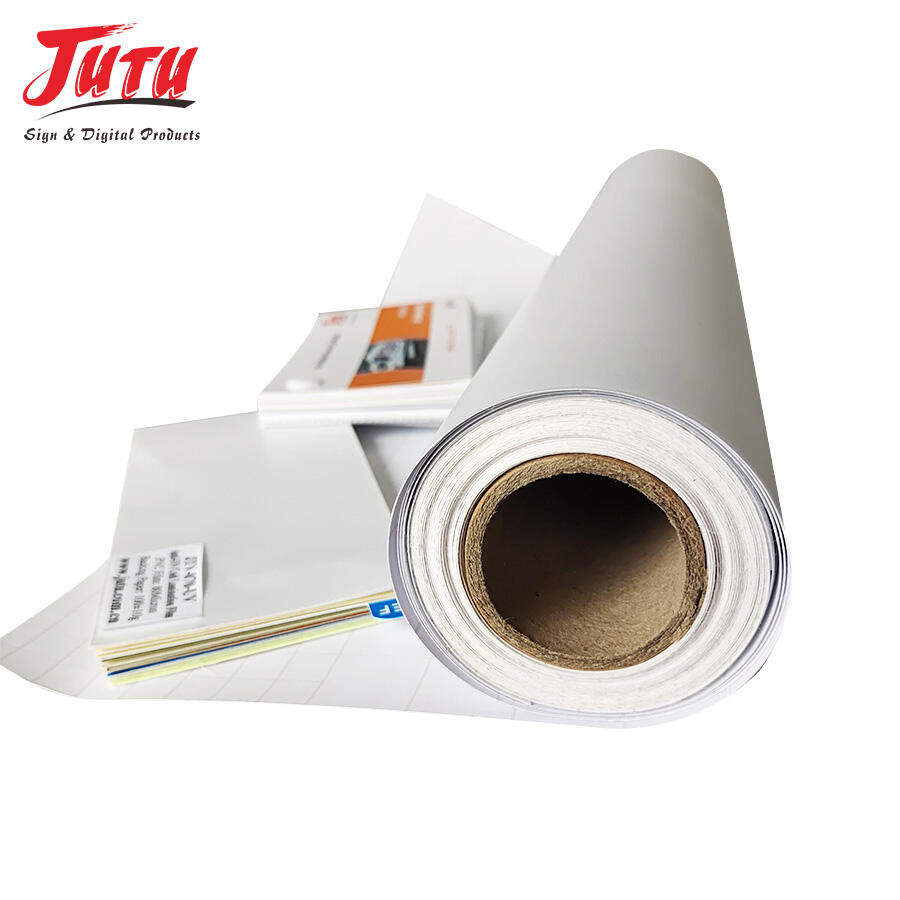

mylar reflective sheeting

Mylar reflective sheeting represents a revolutionary advancement in reflective technology, offering unparalleled performance across diverse industrial and commercial applications. This high-performance material consists of polyester film substrate coated with a precisely engineered reflective layer that maximizes light reflection while maintaining exceptional durability. The core functionality of mylar reflective sheeting centers on its ability to redirect up to 95% of incident light, making it an invaluable solution for grow rooms, greenhouses, solar installations, and architectural projects requiring superior light management. The technological foundation of mylar reflective sheeting incorporates advanced polymer chemistry and precision manufacturing processes that ensure consistent reflectivity across the entire surface area. Unlike traditional reflective materials, mylar reflective sheeting maintains its optical properties under extreme temperature variations, humidity fluctuations, and prolonged exposure to intense lighting conditions. The material's multi-layered construction provides enhanced tear resistance, chemical stability, and dimensional integrity that surpasses conventional alternatives. Applications for mylar reflective sheeting span multiple industries, including horticulture, where it optimizes plant growth by maximizing light distribution and preventing hotspots. Solar energy systems benefit from mylar reflective sheeting's ability to concentrate and redirect sunlight, improving overall system efficiency and energy output. Architectural applications utilize mylar reflective sheeting for daylighting solutions, reducing artificial lighting requirements and enhancing interior illumination quality. The sheeting's flexibility allows for custom installation configurations, accommodating curved surfaces, complex geometries, and specialized mounting requirements. Manufacturing facilities employ mylar reflective sheeting to improve workplace lighting conditions, reduce energy consumption, and create more productive work environments. Research laboratories and testing facilities rely on mylar reflective sheeting's consistent optical properties for accurate measurements and controlled experimental conditions. The material's fire-resistant properties and low outgassing characteristics make it suitable for aerospace applications and cleanroom environments where strict material specifications must be met.