Versatile Applications Across Multiple Industries

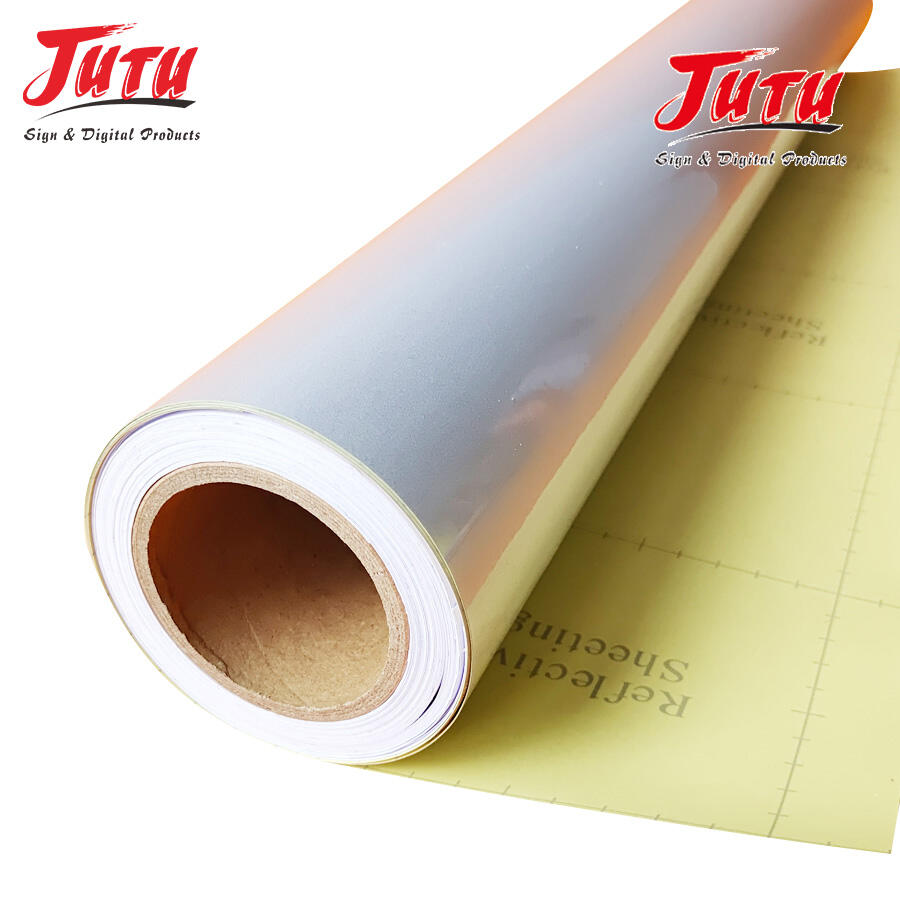

The exceptional versatility of 3M prismatic reflective sheeting enables successful implementation across diverse industries and applications, providing customized visibility solutions that address specific safety challenges and operational requirements in various professional environments. Transportation infrastructure represents the primary application domain, where the material enhances road sign visibility, lane delineation, and vehicle conspicuity treatments that contribute directly to traffic safety improvements and accident reduction. Highway departments utilize the sheeting for regulatory signs, warning devices, and temporary traffic control equipment that must maintain visibility under varying weather and lighting conditions. Emergency response vehicles benefit from enhanced visibility treatments that improve identification during critical situations, potentially reducing response times and improving public safety outcomes. Construction industries employ 3M prismatic reflective sheeting for worker safety applications including high-visibility clothing, equipment marking, and hazard identification systems that protect personnel in dangerous work environments. Industrial facilities integrate the material into safety protocols through machinery marking, emergency exit identification, and personnel protective equipment that enhances workplace safety standards. Marine applications leverage the weather resistance and visibility characteristics for vessel marking, dock identification, and safety equipment enhancement in challenging saltwater environments. Architectural projects incorporate the material for both functional and aesthetic purposes, creating visible building elements that serve safety functions while contributing to design objectives. Consumer applications include outdoor recreational equipment, bicycle safety accessories, and personal protective items that improve individual safety during low-light activities. Agricultural operations utilize the sheeting for equipment visibility, livestock enclosure marking, and operator safety applications in rural environments where lighting may be limited. Mining operations benefit from enhanced equipment visibility and personnel safety marking in underground and surface applications where traditional lighting proves insufficient. Aviation ground support equipment incorporates the material for improved visibility during aircraft servicing operations. Each application requires specific performance characteristics that 3M prismatic reflective sheeting delivers through its superior retroreflectivity, durability, and environmental resistance, making it the preferred choice for professionals demanding reliable visibility enhancement solutions across multiple operational scenarios and challenging environmental conditions.