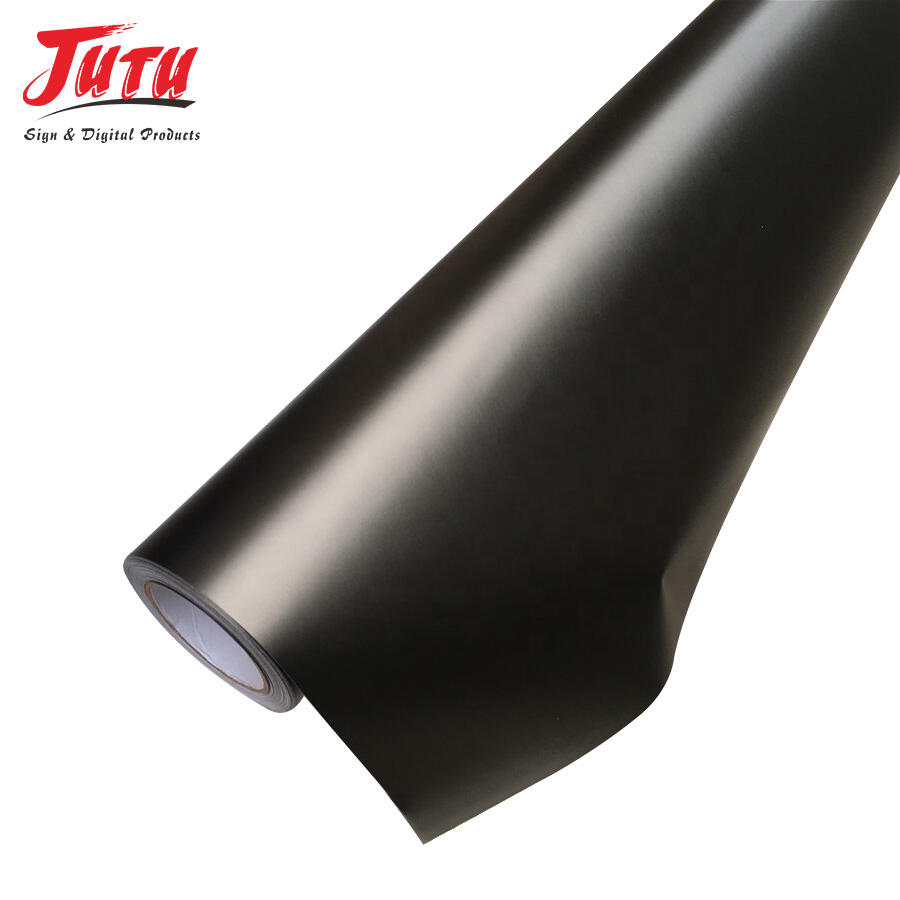

outdoor self adhesive vinyl

Outdoor self adhesive vinyl represents a revolutionary material solution designed specifically for external applications that demand exceptional durability and visual appeal. This premium-grade vinyl material combines advanced polymer chemistry with specialized adhesive technology to create a versatile medium suitable for signage, vehicle wraps, architectural graphics, and countless outdoor marketing applications. The primary function of outdoor self adhesive vinyl centers on providing long-lasting visual communication that withstands harsh environmental conditions while maintaining vibrant colors and crisp graphics. The technological foundation of outdoor self adhesive vinyl relies on multi-layer construction featuring a printable face film, aggressive adhesive layer, and protective liner system. The face film utilizes specialized polymeric materials engineered to resist UV degradation, moisture penetration, and temperature fluctuations common in outdoor environments. Advanced pigmentation technology ensures color stability and prevents fading even under direct sunlight exposure for extended periods. The adhesive system incorporates pressure-sensitive compounds that create permanent bonds with various substrates including metal, plastic, glass, and painted surfaces. Applications for outdoor self adhesive vinyl span multiple industries and use cases. Commercial businesses rely on this material for storefront graphics, directional signage, promotional banners, and brand identification systems. The automotive industry extensively uses outdoor self adhesive vinyl for vehicle wraps, fleet graphics, and decorative applications. Architectural projects benefit from weather-resistant graphics that enhance building aesthetics while providing wayfinding solutions. Event organizers choose outdoor self adhesive vinyl for temporary installations that require professional appearance and reliable performance. The material also serves residential applications including mailbox numbers, decorative accents, and personalized signage. Manufacturing processes for outdoor self adhesive vinyl involve precision coating techniques that ensure uniform thickness and consistent adhesive distribution. Quality control measures include accelerated weathering tests, adhesion strength evaluations, and color fastness assessments that guarantee performance standards. The result is a dependable material that delivers professional results for both amateur crafters and commercial installers seeking reliable outdoor graphics solutions.