Versatile Application Range with Professional Installation Ease

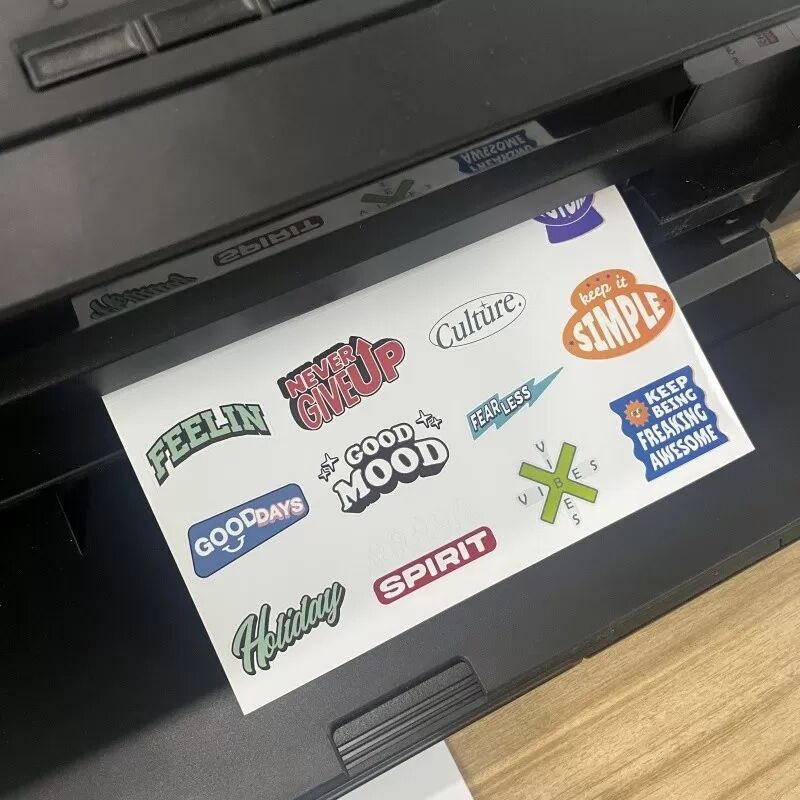

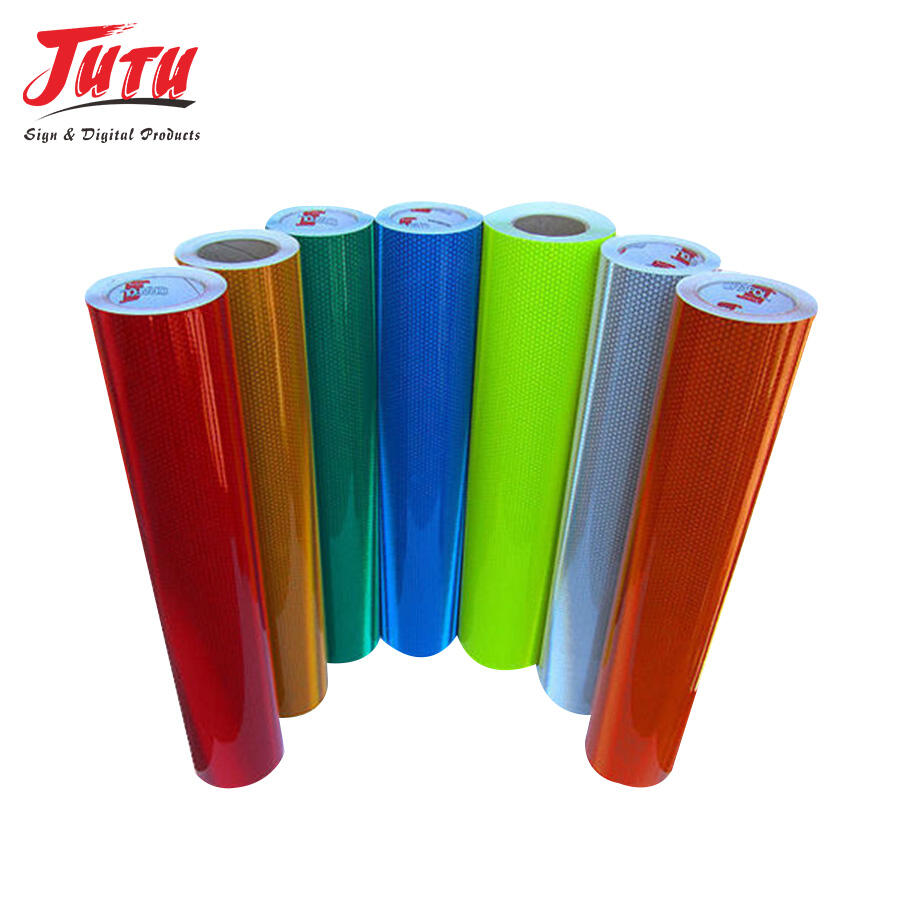

The remarkable versatility of self adhesive vinyl enables successful application across an extensive range of substrates, environments, and project types, making it an invaluable solution for professionals and consumers alike. This adaptability stems from carefully engineered adhesive formulations that provide optimal bonding characteristics for specific substrate categories, including metals, plastics, glass, painted surfaces, and composite materials commonly encountered in modern construction and manufacturing. The installation process requires no specialized equipment, additional adhesives, or extensive surface preparation, allowing for rapid deployment in time-sensitive projects. Professional installers appreciate the material's forgiving nature during positioning phases, with sufficient open time for alignment adjustments before final adhesive activation occurs. The conformability characteristics enable self adhesive vinyl to follow complex surface contours, wrap around edges, and accommodate three-dimensional shapes without creating air pockets or adhesive voids that compromise appearance and performance. This flexibility proves essential in automotive graphics, architectural accent applications, and decorative installations where precise surface conformance determines project success. The material's dimensional stability prevents shrinkage, expansion, or distortion during installation and subsequent service, ensuring that graphics maintain their intended appearance and registration over time. Quality self adhesive vinyl formulations offer various adhesive strengths ranging from removable formulations for temporary applications to permanent systems for long-term installations, providing flexibility for diverse project requirements. The wide selection of surface finishes includes gloss, matte, textured, and specialty options such as metallic, reflective, and color-changing variants that enable creative expression and functional enhancement. Digital compatibility allows for custom printing directly onto the vinyl surface, creating unlimited design possibilities for branding, signage, and decorative applications. The material's compatibility with standard cutting equipment facilitates precise shape creation, intricate designs, and efficient production workflows that minimize waste and maximize productivity in commercial applications.