Versatile Installation Options and Broad Application Compatibility

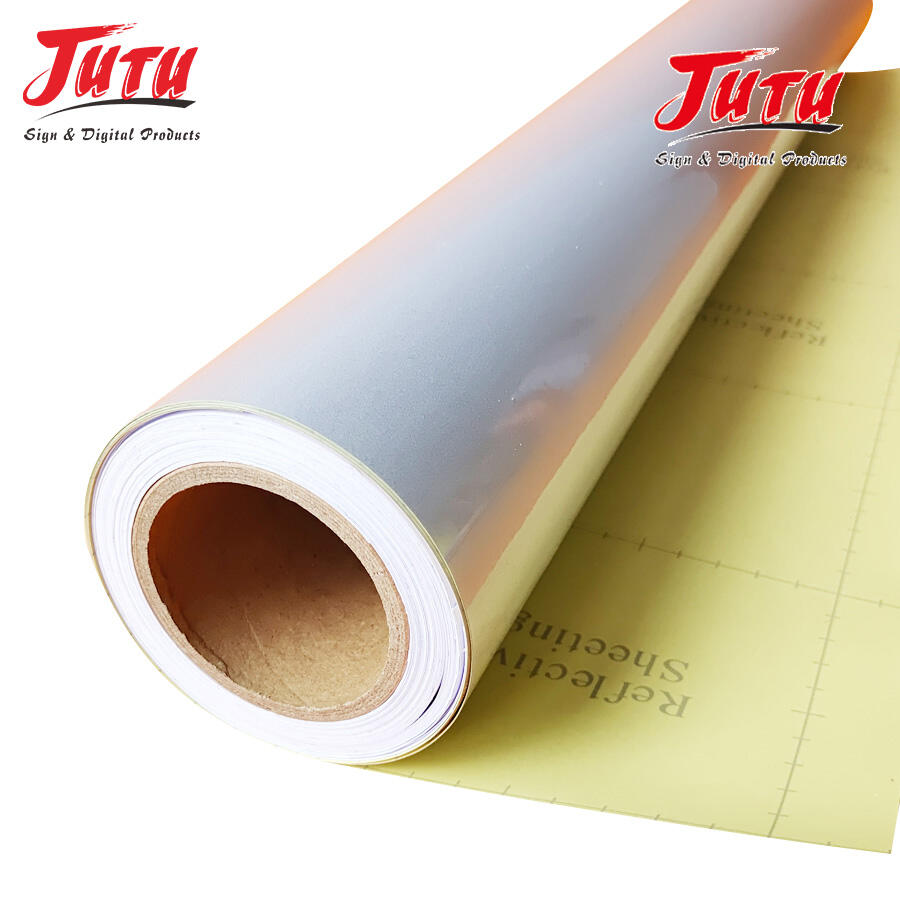

The versatility of sheets of reflective material manifests through their adaptability to diverse installation scenarios and compatibility with various substrates and mounting systems. These materials are engineered to conform to different surface profiles including flat, curved, and irregular geometries, making them suitable for both new construction and retrofit applications. Flexible substrate options allow sheets of reflective material to be installed over existing insulation, structural members, and equipment housings without requiring extensive surface preparation or modification. Multiple attachment methods including adhesive backing, mechanical fasteners, and integrated mounting systems provide installation flexibility to match specific project requirements and local building codes. The materials can be cut, shaped, and fitted using standard construction tools, eliminating the need for specialized equipment or extensive training for installation personnel. Compatibility with different building materials including metal, wood, concrete, and composite surfaces ensures broad application potential across various construction types and architectural styles. Sheets of reflective material integrate seamlessly with existing HVAC systems, building automation controls, and energy management systems without requiring system modifications or recalibration. Modular design options allow for scalable installations from small residential applications to large commercial and industrial facilities, providing cost-effective solutions across different project sizes. The materials accommodate various thickness requirements and performance specifications, enabling customization for specific thermal performance targets or space constraints. Installation guidance and technical support help ensure proper deployment while maximizing performance benefits and warranty coverage. Retrofit applications particularly benefit from the non-invasive installation characteristics, allowing building owners to upgrade energy efficiency without disrupting occupancy or operations. Quality sheets of reflective material maintain performance consistency across different installation orientations and angles, providing design flexibility for architects and engineers. The versatility extends to specialized applications including transportation, aerospace, and industrial process equipment where custom configurations and performance requirements demand adaptable material solutions.