Versatile Application Flexibility for Diverse Safety Requirements

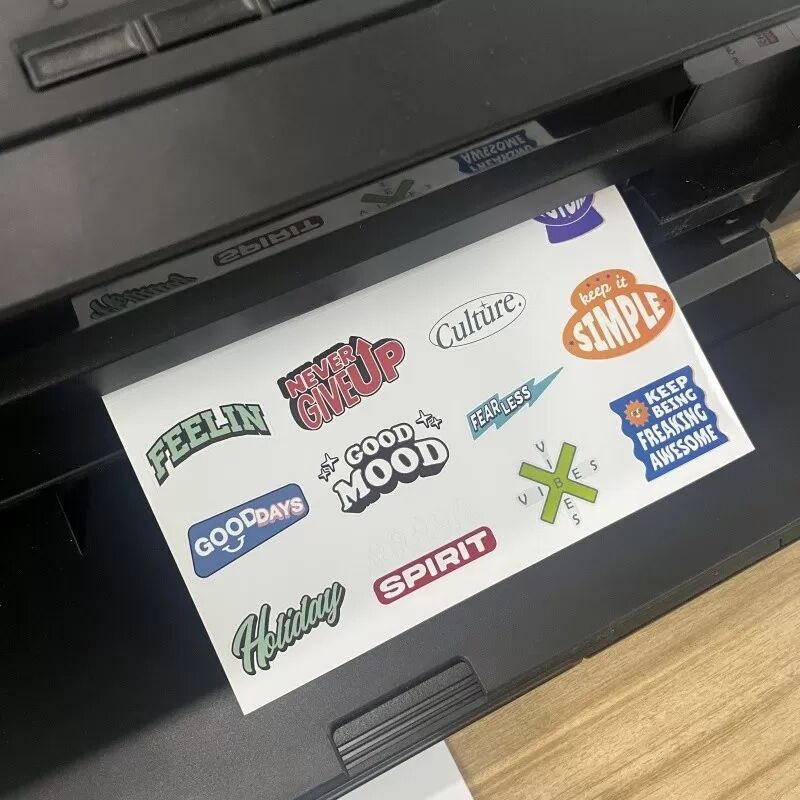

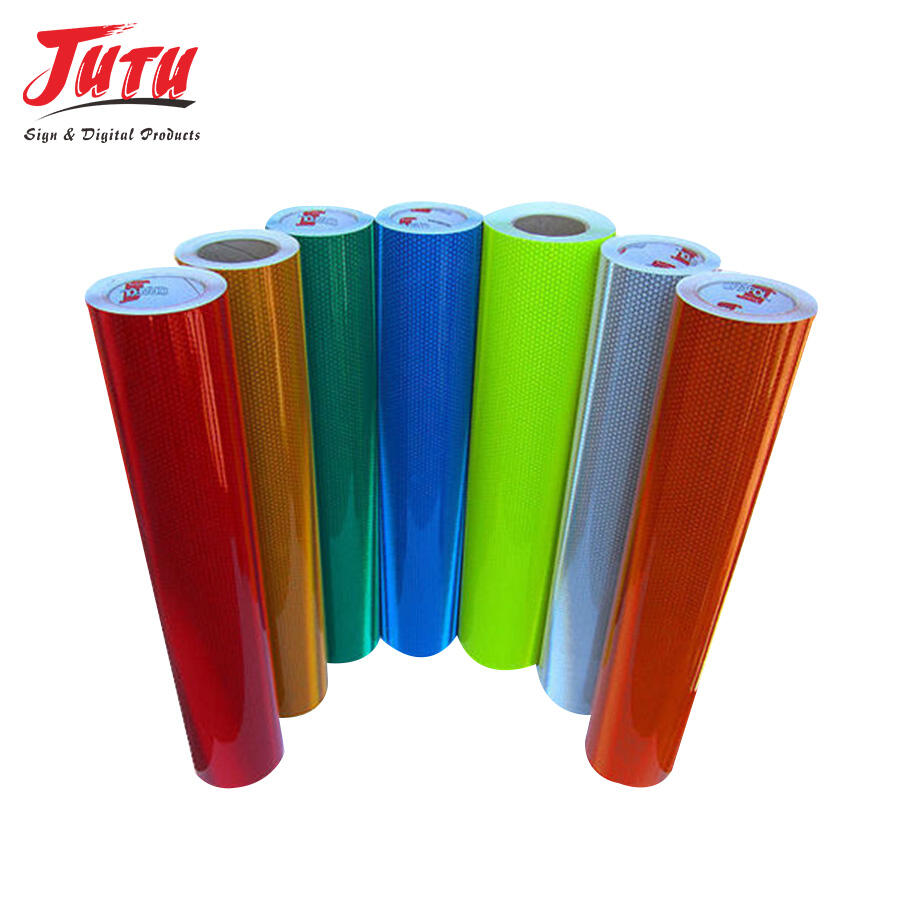

The remarkable application versatility of high intensity prismatic reflective sheeting enables its successful deployment across an extensive range of safety and visibility enhancement requirements, from traffic control systems to industrial safety applications, marine environments, and specialized emergency response equipment. This flexibility stems from the material's ability to conform to complex geometries while maintaining optimal optical performance, combined with multiple adhesive options and substrate compatibility characteristics that accommodate virtually any installation requirement. The conformability properties allow high intensity prismatic reflective sheeting to follow curved surfaces, compound angles, and irregular shapes without compromising the prismatic optical structure that delivers superior retroreflective performance. This characteristic proves invaluable for applications involving cylindrical objects, curved signage, vehicle body contours, and complex architectural features where traditional rigid reflective materials would fail to provide adequate coverage or would require complex fabrication procedures. The material's flexibility also enables field installation without specialized tools or heating equipment, simplifying deployment procedures and reducing installation costs. Color options and customization capabilities provide additional versatility, with high intensity prismatic reflective sheeting available in standard colors including white, yellow, red, orange, blue, and green, as well as specialized colors for specific applications. Each color option maintains the same optical performance characteristics, ensuring consistent visibility enhancement regardless of the selected color scheme. Custom printing capabilities enable the incorporation of text, graphics, and logos directly onto the reflective surface without compromising optical performance, creating opportunities for branded safety applications and specialized identification requirements. The adhesive system options include permanent, removable, and repositionable formulations that address different installation requirements and substrate characteristics. Permanent adhesives provide maximum bonding strength for long-term installations on clean, smooth surfaces, while removable options enable temporary applications or installations requiring periodic repositioning. The substrate compatibility encompasses metals, plastics, composites, painted surfaces, and specialty materials, ensuring successful bonding across diverse application requirements. Manufacturing options include roll goods for large-area applications, pre-cut shapes for standardized installations, and custom die-cut configurations for specialized requirements, providing procurement flexibility that matches specific project needs while minimizing material waste and installation complexity.