Versatile Design Options and Customization Capabilities

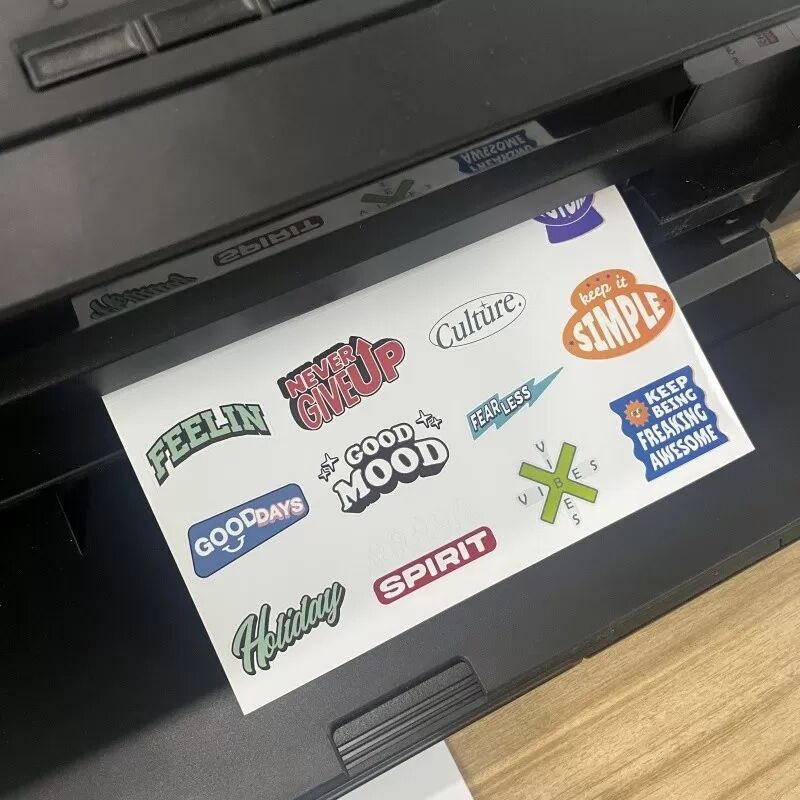

The design flexibility inherent in stickable vinyl opens unlimited creative possibilities for both commercial and residential applications, accommodating diverse aesthetic preferences and functional requirements. Modern printing technologies enable the reproduction of virtually any design, pattern, texture, or color scheme with exceptional accuracy and detail resolution. Digital printing processes can recreate photographic images, complex graphics, architectural textures, or custom artwork with professional quality results that rival traditional materials at a fraction of the cost. The material serves as an ideal canvas for corporate branding applications, allowing businesses to display logos, promotional messages, or branded graphics with consistent color reproduction and sharp detail clarity. Custom sizing options eliminate waste and ensure perfect fit for specific applications, whether covering small accent areas or large commercial installations. The ability to print custom designs means users are not limited to standard patterns or colors available in traditional materials, enabling truly unique installations that reflect individual style or brand identity. Textural variations in stickable vinyl can simulate natural materials including wood grain, stone patterns, fabric textures, or metallic finishes, providing authentic appearance without the weight, cost, or maintenance requirements of genuine materials. Specialty finishes such as matte, gloss, satin, or textured surfaces add tactile interest and visual depth to installations while maintaining the practical benefits of the vinyl substrate. The material accommodates both subtle design elements and bold statement pieces, adapting to conservative professional environments or creative spaces that demand visual impact. Color matching capabilities ensure consistency across multiple pieces or phases of installation, critical for commercial applications where brand standards must be maintained. The printing process can incorporate special effects including gradients, shadows, highlights, and dimensional elements that create sophisticated visual presentations previously achievable only through expensive custom manufacturing. Installation flexibility allows creative applications including layering different designs, creating geometric patterns, or combining multiple colors and textures within single projects for complex artistic expressions.