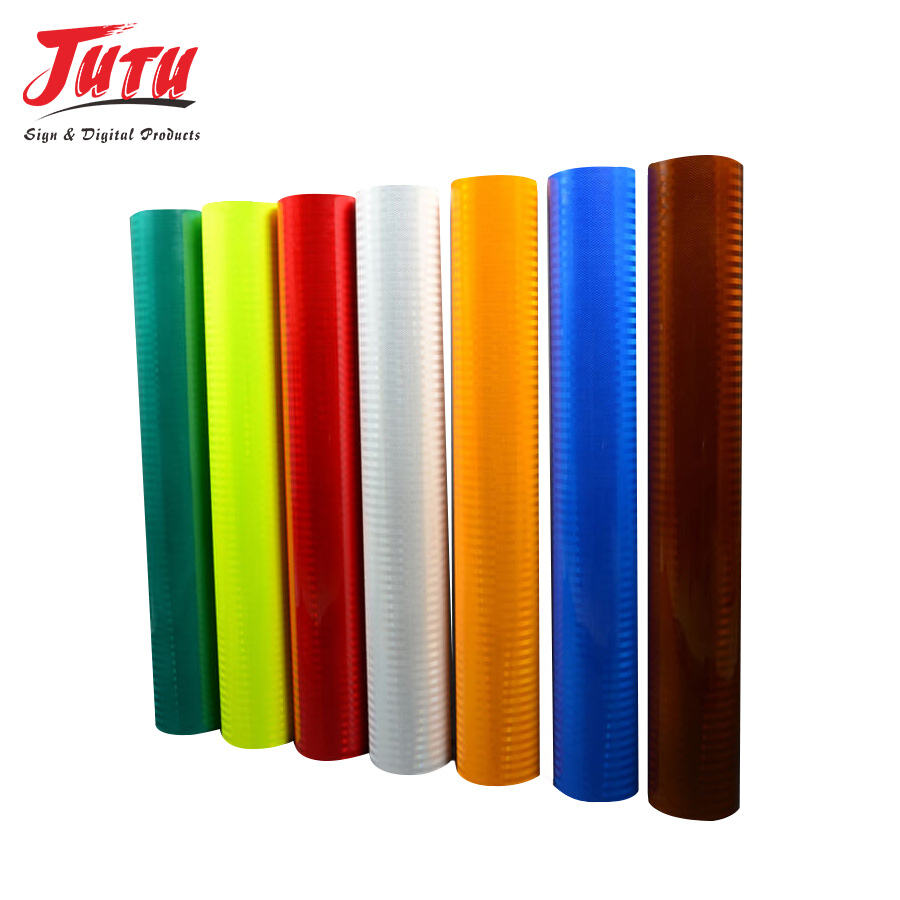

white reflective sheeting

White reflective sheeting represents a revolutionary advancement in protective material technology, designed to maximize light reflection while providing exceptional durability and versatility across numerous applications. This specialized material combines advanced polymer technology with precision-engineered reflective properties to deliver superior performance in demanding environments. The primary function of white reflective sheeting centers on its ability to reflect up to 95% of incident light, making it an invaluable solution for applications requiring enhanced visibility, temperature control, and energy efficiency. The technological foundation of this material relies on micro-structured surfaces and specialized coating formulations that optimize reflective properties while maintaining structural integrity. White reflective sheeting incorporates advanced UV-resistant polymers that prevent degradation from prolonged sun exposure, ensuring long-term performance consistency. The material features exceptional adhesive backing systems that provide reliable bonding to various substrates including metals, plastics, concrete, and composite materials. Manufacturing processes utilize precision extrusion and lamination techniques to achieve uniform thickness and consistent reflective properties across entire sheets. The sheeting demonstrates remarkable flexibility, allowing installation on curved surfaces and complex geometries without compromising performance. Temperature resistance ranges from -40°F to 180°F, enabling applications in extreme climate conditions. The material exhibits excellent chemical resistance against common industrial solvents, acids, and alkaline solutions. Construction applications include building envelope systems, roofing membranes, and architectural cladding where thermal management is critical. Transportation sectors utilize white reflective sheeting for vehicle wraps, trailer coverings, and safety markings. Industrial facilities employ this material for equipment protection, pipeline insulation, and warehouse cooling systems. Agricultural applications encompass greenhouse coverings, crop protection films, and livestock shelter enhancements.