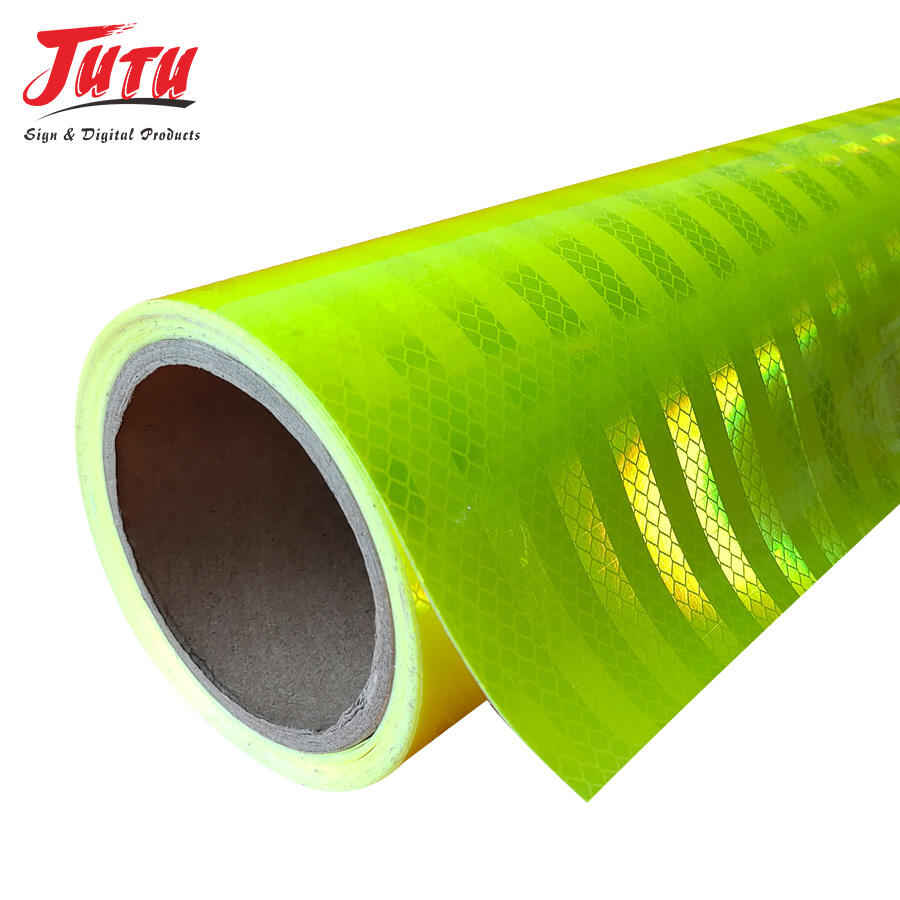

micro prismatic reflective sheeting

Micro prismatic reflective sheeting represents a revolutionary advancement in retroreflective technology, designed to enhance visibility and safety across numerous applications. This innovative material utilizes precision-engineered microscopic prisms that redirect light back to its source with exceptional efficiency. The micro prismatic reflective sheeting consists of thousands of tiny cube-corner retroreflectors arranged in a systematic pattern, creating a surface that delivers superior brightness and clarity compared to traditional glass bead reflective materials. The technological foundation of micro prismatic reflective sheeting relies on total internal reflection principles, where light enters each prism and bounces between three mutually perpendicular surfaces before returning directly toward the light source. This optical phenomenon ensures maximum luminance across wide observation angles, making the material highly effective for both daytime and nighttime visibility applications. The manufacturing process involves sophisticated molding techniques that create uniform prism structures with precise geometric specifications, resulting in consistent performance characteristics throughout the entire sheet surface. Modern micro prismatic reflective sheeting incorporates advanced polymer substrates that provide exceptional durability, weather resistance, and flexibility while maintaining optimal optical properties. The material's construction typically includes multiple layers: a clear protective film, the prismatic retroreflective layer, an adhesive system, and a removable liner for easy application. Key applications for micro prismatic reflective sheeting span transportation infrastructure, including highway signs, vehicle markings, construction zone delineation, and emergency vehicle identification. Industrial safety applications encompass personal protective equipment, facility markings, and hazard identification systems. The material also finds extensive use in maritime applications for vessel marking and navigation aids, architectural applications for building safety features, and consumer products requiring enhanced visibility. The versatility of micro prismatic reflective sheeting extends to specialized applications such as airport runway markings, railway safety systems, and emergency evacuation guidance systems, where reliable visibility under varying lighting conditions proves essential for operational safety and regulatory compliance.