3m cold laminating film

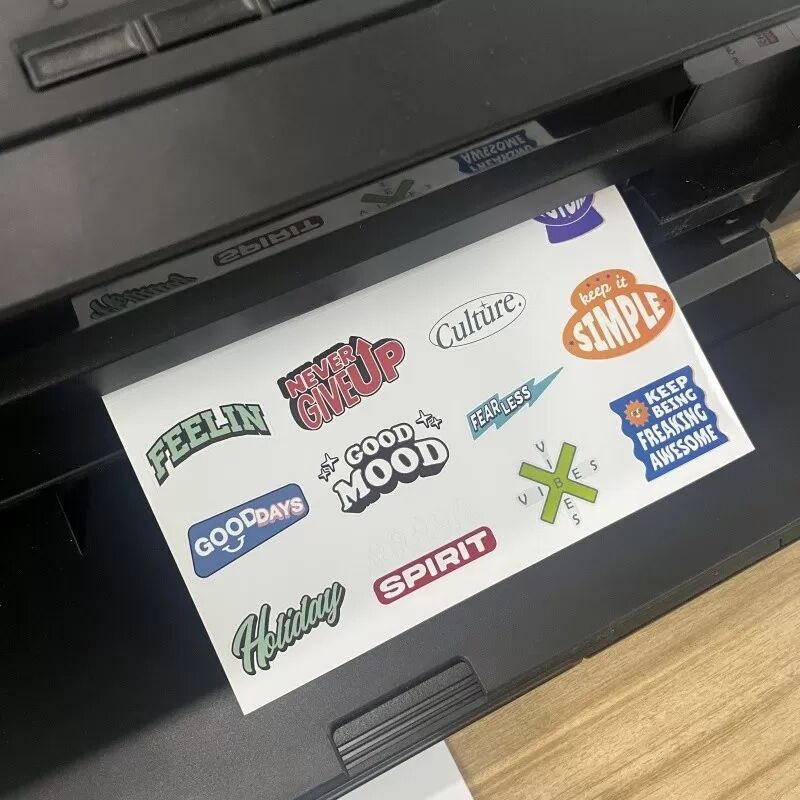

The 3m cold laminating film represents a revolutionary advancement in document protection and enhancement technology that delivers professional-grade results without requiring heat or specialized equipment. This innovative protective solution utilizes pressure-sensitive adhesive technology to create durable, crystal-clear barriers that safeguard important documents, photographs, and signage materials from environmental damage. The 3m cold laminating film features a sophisticated multi-layer construction that combines optical clarity with exceptional durability, making it an ideal choice for businesses, educational institutions, and professional service providers who demand reliable document preservation solutions. The film's advanced adhesive system ensures bubble-free application while maintaining repositionability during initial placement, allowing users to achieve flawless results even without extensive laminating experience. This versatile protection system accommodates various substrate materials including paper, cardstock, photographs, and lightweight fabrics, making it suitable for diverse applications ranging from office documentation to retail displays. The 3m cold laminating film incorporates UV-resistant properties that prevent yellowing and degradation over time, ensuring long-term visual integrity of laminated materials. Its chemical composition resists common environmental contaminants such as moisture, oils, and fingerprints, maintaining pristine appearance throughout extended use periods. The film's dimensional stability prevents warping or curling under normal storage conditions, making it particularly valuable for archival applications where document flatness is critical. Professional users appreciate the consistent thickness tolerance and superior optical properties that eliminate distortion and maintain true color reproduction of underlying materials. The 3m cold laminating film supports both manual and machine application methods, providing flexibility for different workflow requirements and production volumes while maintaining consistent quality standards across all application techniques.