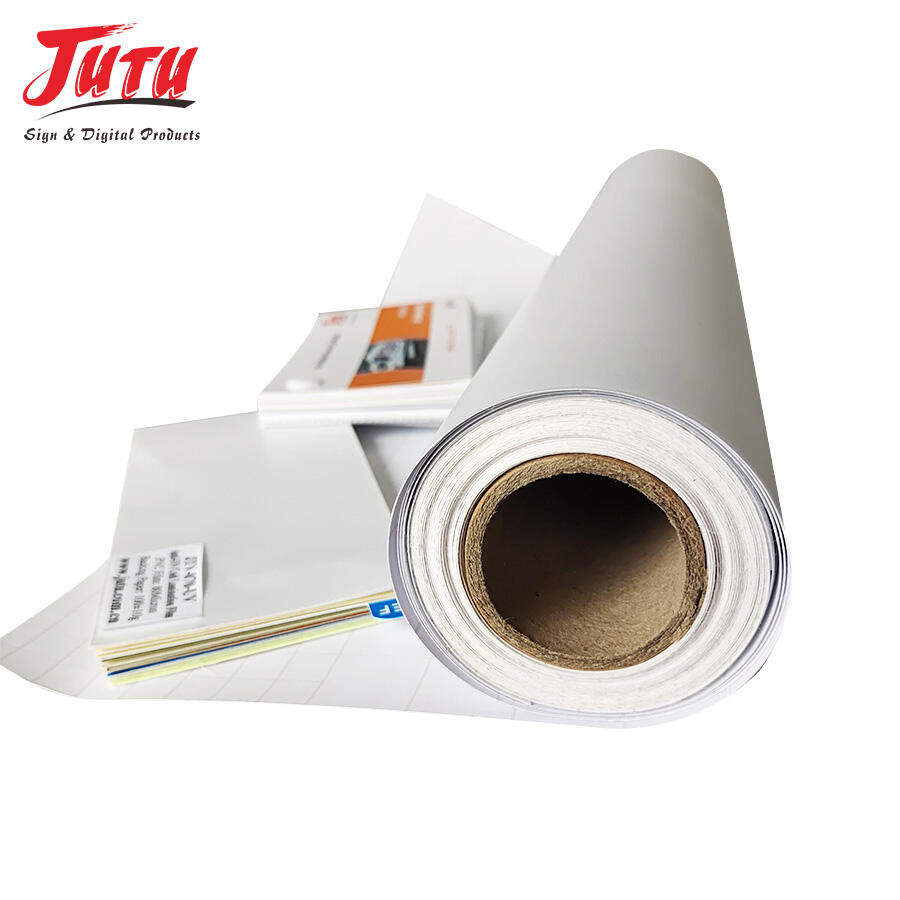

matte cold lamination film

Matte cold lamination film represents a revolutionary advancement in document protection and enhancement technology, offering users a sophisticated solution for preserving and improving the appearance of various printed materials. This specialized protective coating utilizes pressure-sensitive adhesive technology that eliminates the need for heat application during the lamination process. The film creates a smooth, non-reflective surface that reduces glare while maintaining excellent clarity and readability of underlying content. Unlike traditional hot lamination methods, matte cold lamination film operates at room temperature, making it safe for heat-sensitive materials such as photographs, inkjet prints, and thermal-sensitive documents. The film consists of multiple layers, including a polyester base substrate, an adhesive layer, and a protective release liner that ensures proper application. Its matte finish provides a professional, sophisticated appearance that enhances the visual appeal of documents while offering superior protection against moisture, fingerprints, and everyday wear. The technological features of this film include exceptional dimensional stability, ensuring that laminated materials maintain their original size and shape without warping or shrinking over time. The adhesive formulation provides strong bonding without bubbling or edge lifting, creating a permanent seal that withstands various environmental conditions. Applications for matte cold lamination film span across multiple industries and use cases. Educational institutions utilize this technology for protecting teaching materials, student certificates, and reference documents. Photography studios and print shops rely on it for enhancing and preserving high-quality prints, portfolios, and artwork reproductions. Corporate environments benefit from its use in protecting important presentations, marketing materials, and identification cards. The film proves invaluable for outdoor signage applications where weather resistance and glare reduction are essential. Menu lamination in restaurants and hospitality venues represents another significant application area, where the film's resistance to spills and easy cleaning properties provide practical advantages. Medical and laboratory environments utilize matte cold lamination film for protecting charts, protocols, and reference materials that require frequent handling and cleaning.