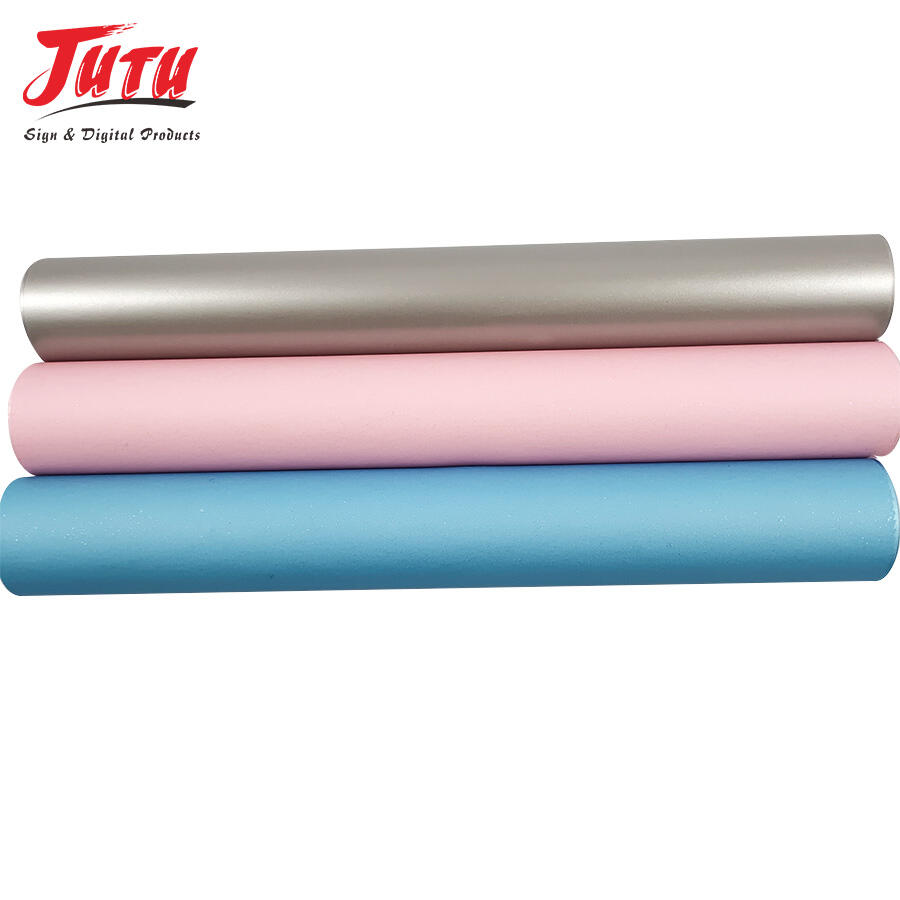

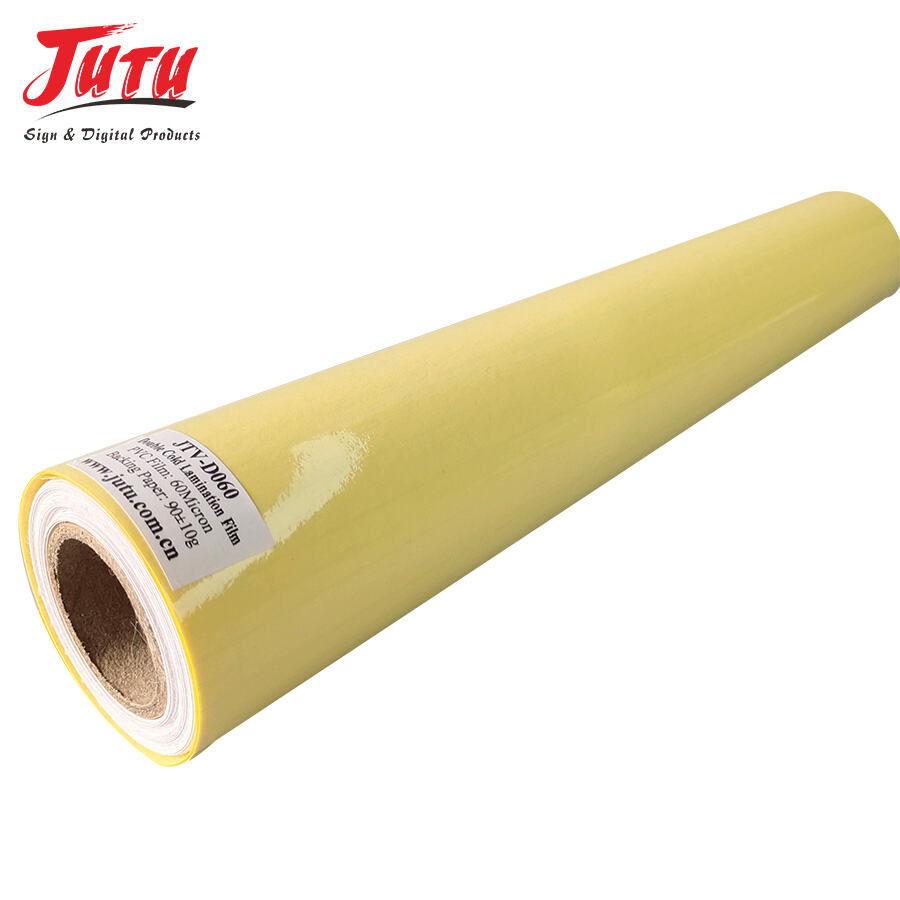

cold lamination film manufacturer

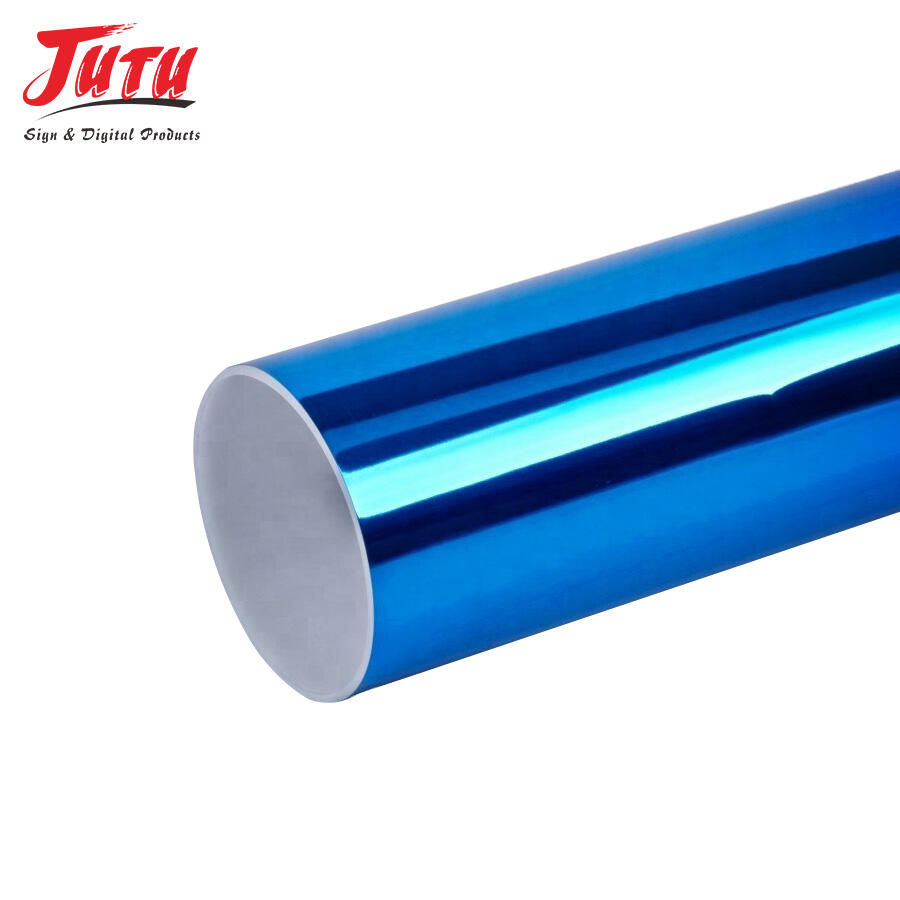

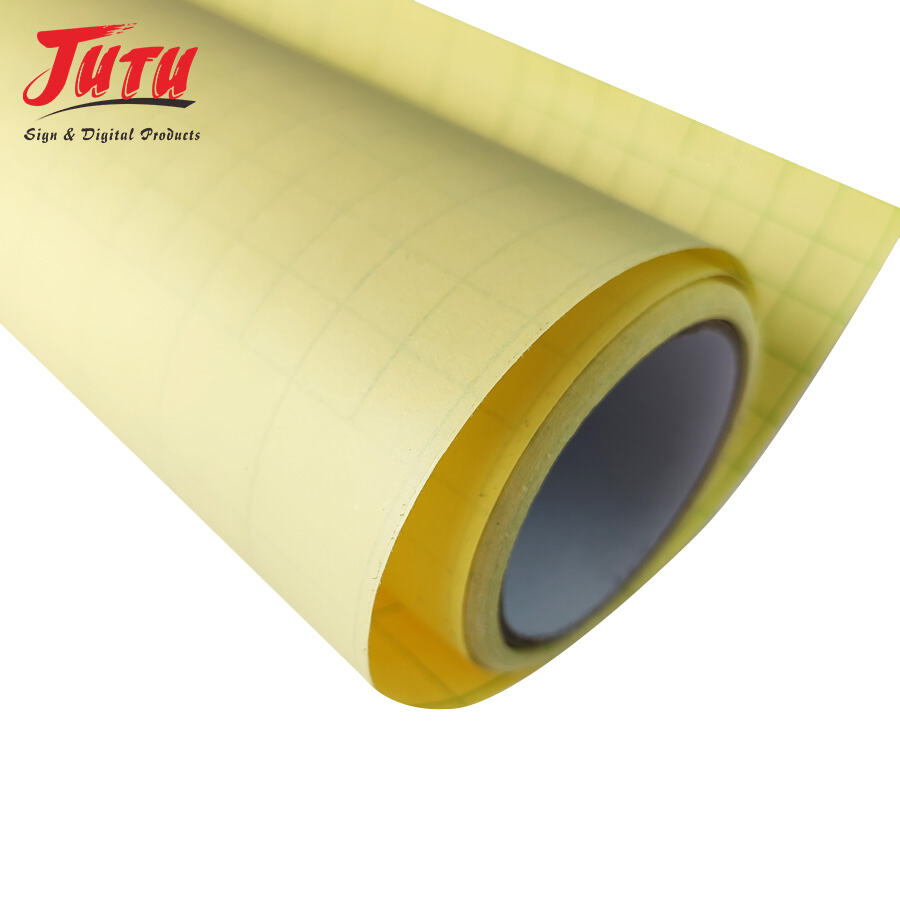

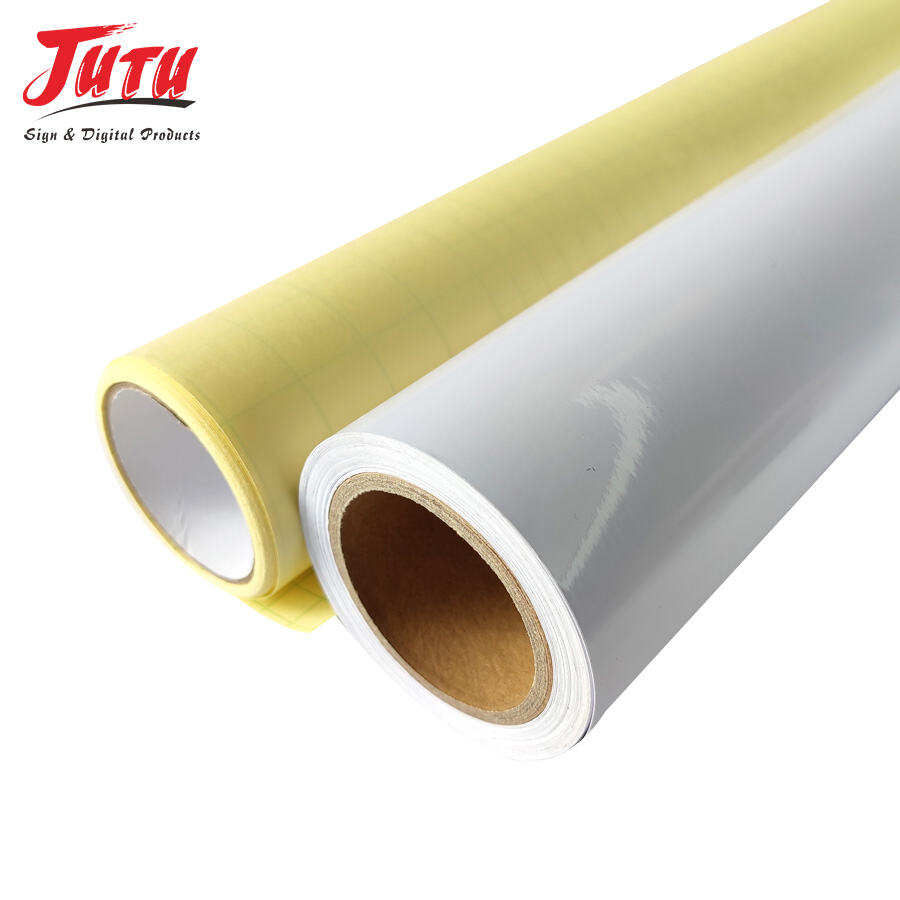

A cold lamination film manufacturer specializes in producing advanced protective films that bond to various substrates without requiring heat activation. These manufacturers utilize sophisticated production processes to create durable, transparent films that preserve and enhance printed materials, photographs, documents, and signage. The primary function of a cold lamination film manufacturer centers on developing films with pressure-sensitive adhesives that create permanent or removable bonds at room temperature. Their manufacturing facilities employ precision coating technologies to ensure consistent adhesive distribution and optimal film clarity. These manufacturers focus on creating products that offer superior optical properties, maintaining the original appearance of laminated items while providing exceptional protection against environmental factors. The technological features of modern cold lamination film manufacturers include multi-layer extrusion capabilities, advanced adhesive formulation laboratories, and quality control systems that monitor thickness uniformity, adhesion strength, and optical clarity throughout production. Many manufacturers incorporate UV-resistant additives and anti-static properties into their films, extending product longevity and performance. Applications for products from cold lamination film manufacturers span numerous industries including commercial printing, photography studios, educational institutions, retail environments, and architectural sectors. Print shops rely on these films to protect posters, banners, and marketing materials, while photographers use them to preserve precious memories and artistic works. Educational facilities utilize cold lamination films for creating durable learning materials, maps, and instructional displays. The retail industry depends on these films for point-of-sale materials, menu boards, and promotional signage that must withstand frequent handling and environmental exposure. Architectural applications include protective films for glass surfaces, decorative panels, and wayfinding systems in commercial buildings and public spaces.