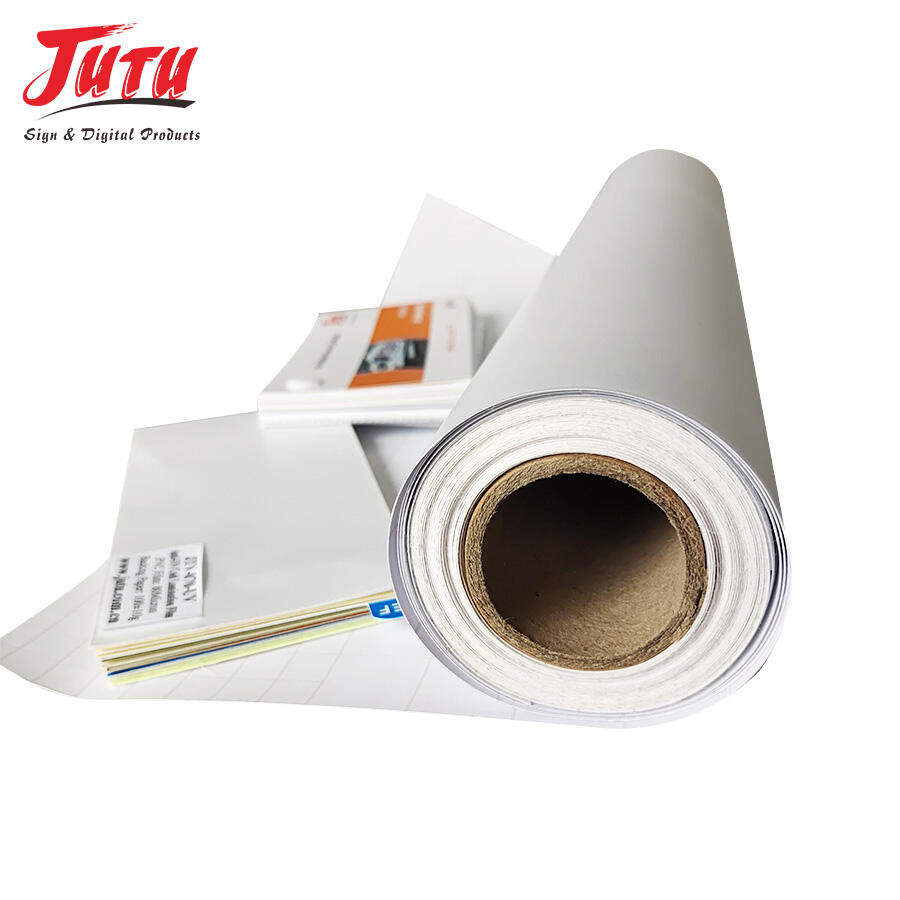

holographic cold lamination film

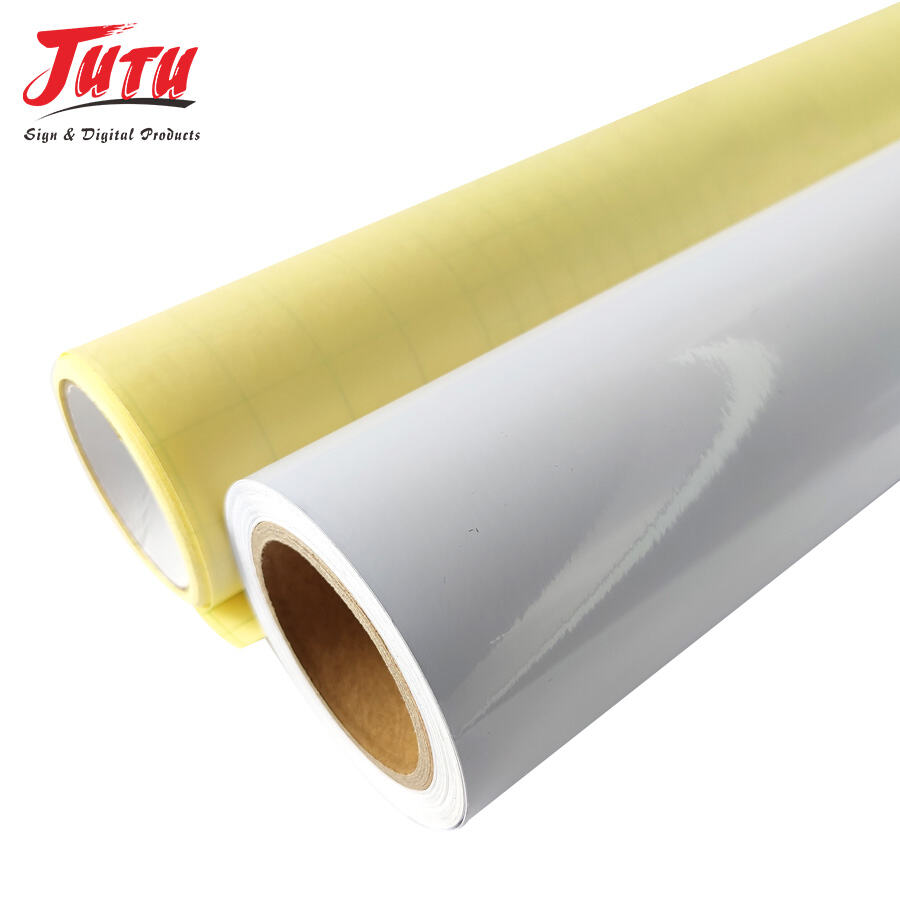

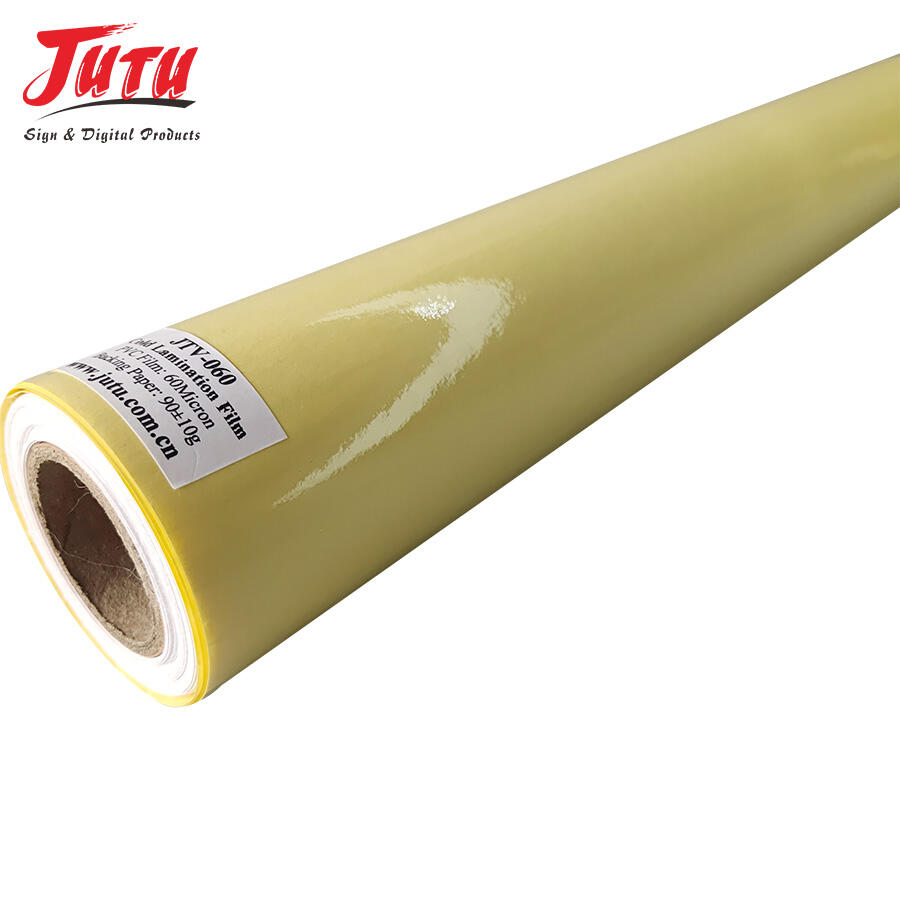

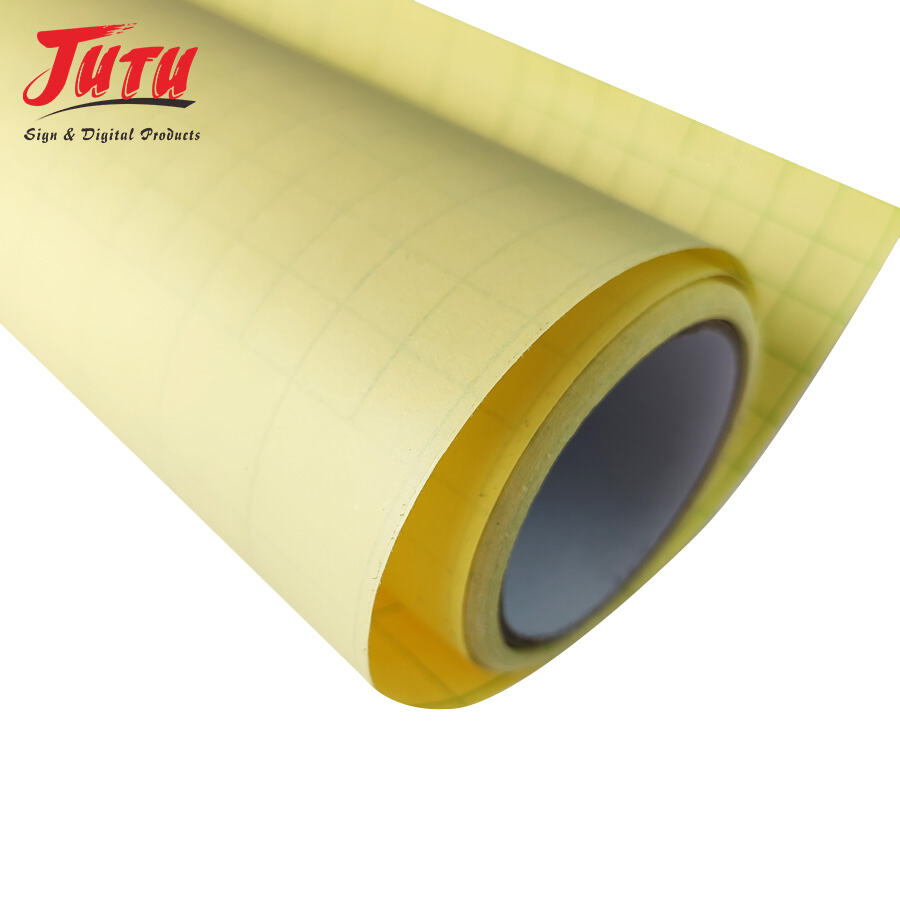

Holographic cold lamination film represents a revolutionary advancement in protective coating technology, combining visual appeal with superior surface protection capabilities. This innovative material features a unique holographic pattern that creates stunning three-dimensional visual effects while providing comprehensive protection for printed materials, documents, and decorative surfaces. Unlike traditional hot lamination processes that require heat application, holographic cold lamination film utilizes pressure-sensitive adhesive technology, making it safer and more energy-efficient for various applications. The film consists of multiple layers including a transparent protective layer, holographic embossed substrate, and high-performance adhesive backing that ensures permanent bonding without bubbling or peeling. The holographic cold lamination film offers exceptional clarity and optical properties, maintaining the original quality of underlying graphics while adding spectacular rainbow-like effects that change appearance based on viewing angles. This technology serves multiple industries including packaging, advertising, security printing, and decorative applications where both protection and visual impact are essential. The film provides excellent resistance against moisture, UV radiation, scratches, and general wear, significantly extending the lifespan of laminated materials. Manufacturing processes involve precise embossing techniques that create microscopic surface patterns responsible for the holographic effects, combined with advanced adhesive formulations that ensure consistent performance across different substrates. The holographic cold lamination film maintains flexibility and durability even under varying temperature conditions, making it suitable for both indoor and outdoor applications. Its versatility extends to compatibility with various printing methods including digital, offset, and screen printing, allowing seamless integration into existing production workflows without requiring specialized equipment modifications.