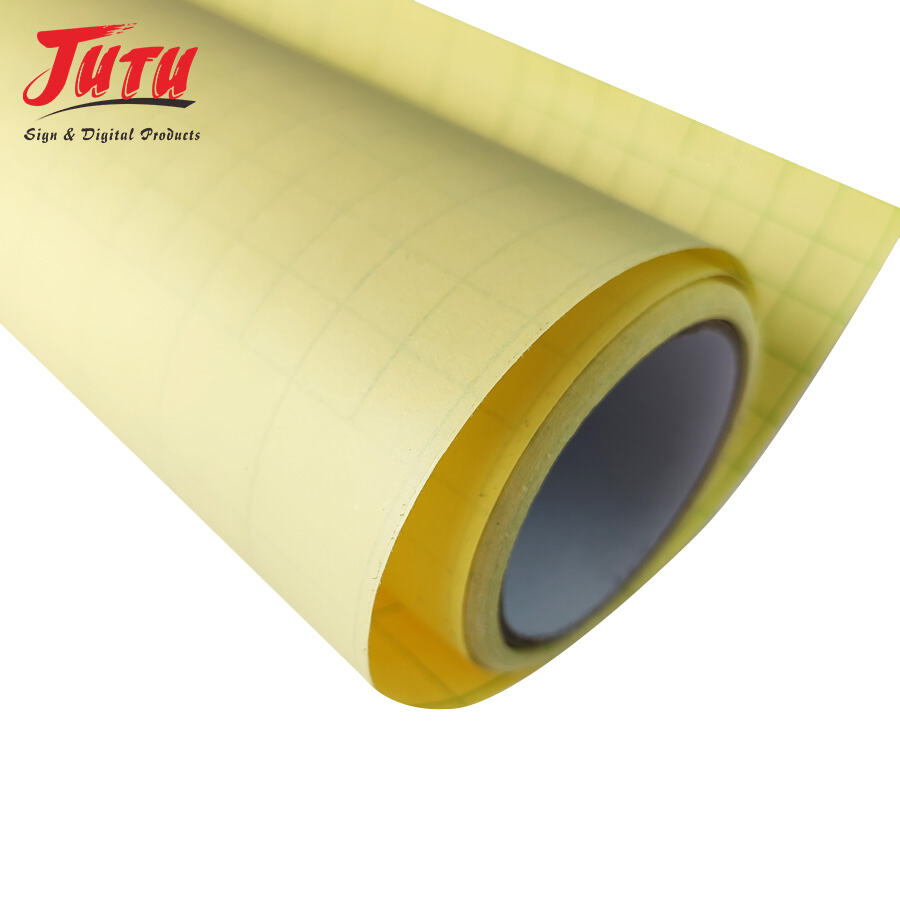

cold lamination film

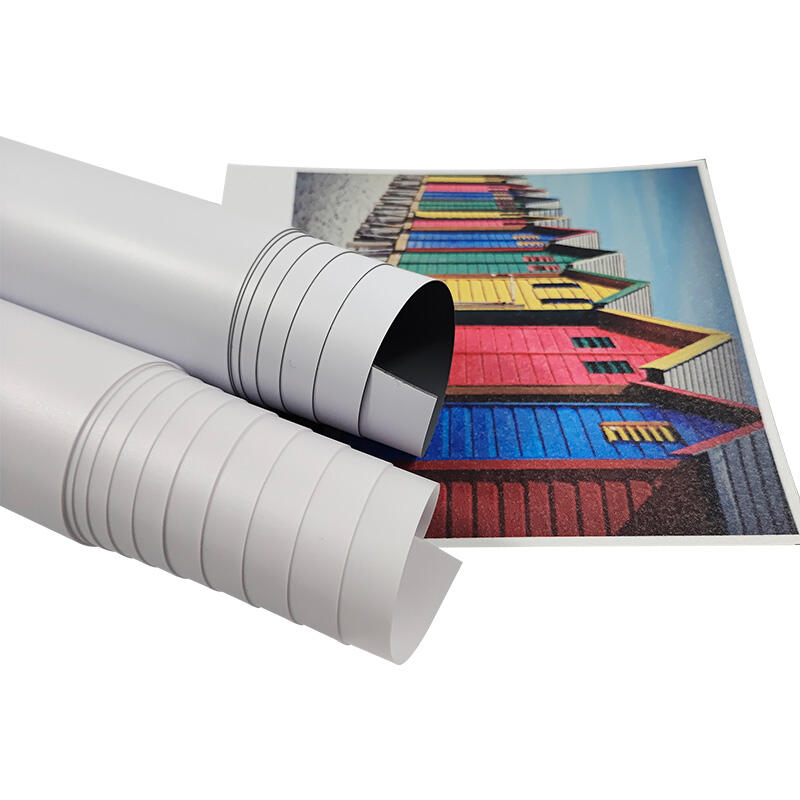

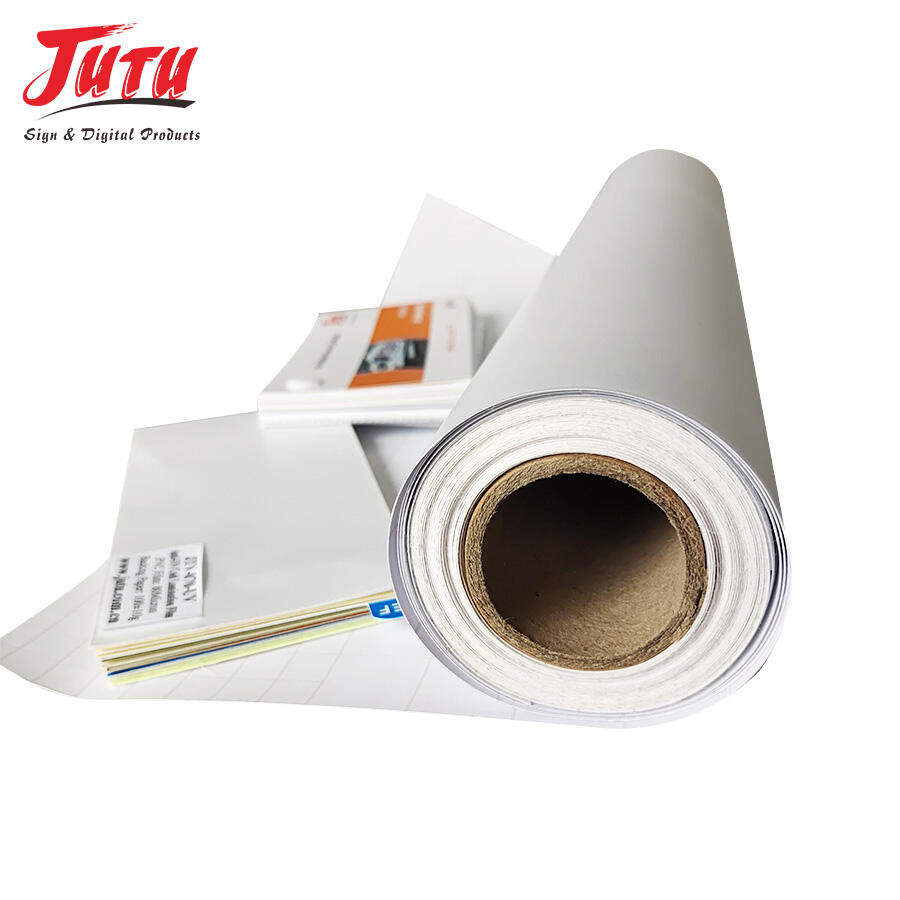

Cold lamination film represents a revolutionary advancement in document protection and enhancement technology, offering users an efficient solution for preserving important materials without the need for heat application. This innovative protective coating system utilizes pressure-sensitive adhesive technology to create durable, crystal-clear barriers that safeguard documents, photographs, signage, and various printed materials from environmental damage, moisture, UV rays, and everyday wear. The cold lamination film process eliminates traditional thermal requirements, making it ideal for heat-sensitive substrates that might warp, discolor, or deteriorate under conventional hot lamination procedures. The film consists of multiple specialized layers, including a protective carrier sheet, pressure-activated adhesive layer, and optionally anti-glare or anti-static treatments depending on specific application requirements. Modern cold lamination film formulations incorporate advanced polymer technologies that ensure exceptional clarity, superior adhesion properties, and long-term durability without compromising the original appearance of protected materials. The application process involves removing the protective backing and applying controlled pressure to activate the adhesive bond, creating an immediate protective seal that resists peeling, bubbling, or delamination. This versatile protection solution serves numerous industries including education, healthcare, retail, hospitality, and corporate environments where document preservation, signage protection, and material enhancement are essential. The cold lamination film technology supports various thickness options, surface finishes including matte and gloss variations, and specialized formulations designed for outdoor applications, food contact surfaces, and archival document preservation. Professional-grade cold lamination film systems deliver consistent results across different substrate types, from standard paper and cardstock to synthetic materials, photographs, and digital prints, ensuring reliable protection regardless of the underlying material composition.