Exceptional Versatility Across Multiple Industries

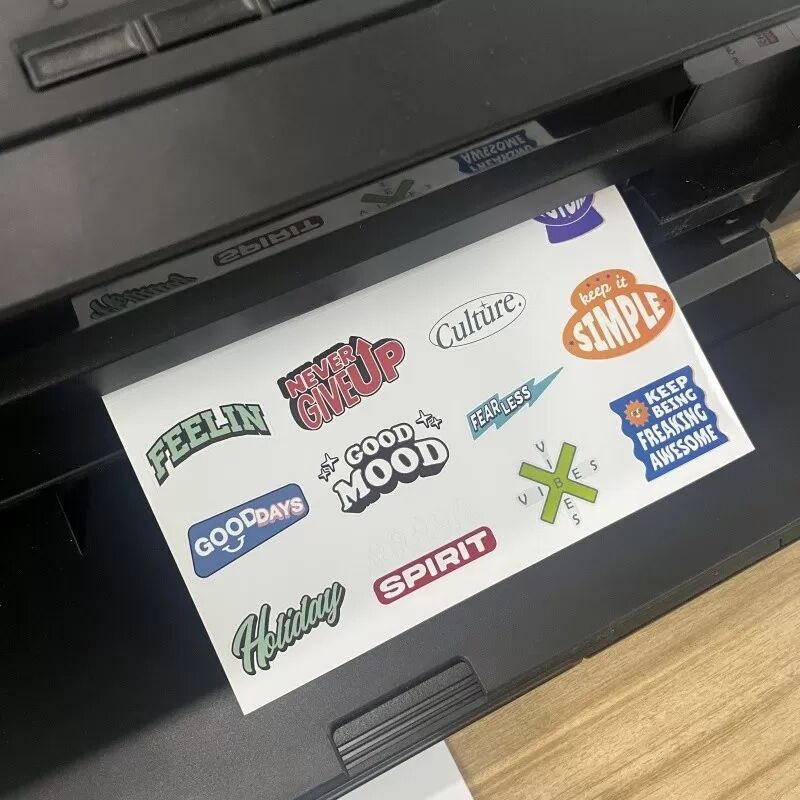

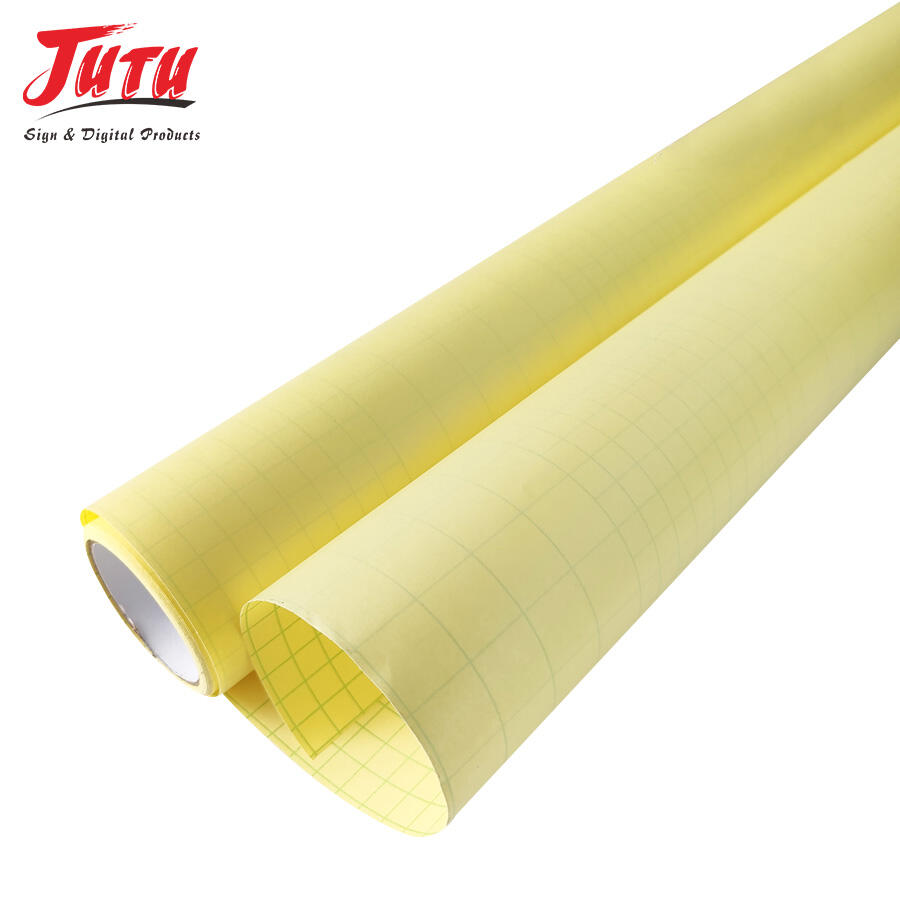

Cold lamination films demonstrate unparalleled versatility by serving diverse industries and applications with consistent excellence, making them indispensable for businesses ranging from commercial printing to educational institutions. The printing industry benefits tremendously from cold lamination films' compatibility with all major printing technologies, including digital inkjet, laser printing, offset lithography, and screen printing processes. These films protect valuable prints, photographs, and artwork from fading, moisture damage, and physical wear while maintaining optical clarity and color vibrancy. Educational environments utilize cold lamination films for creating durable teaching materials, protecting important documents, and preserving student artwork for extended display periods. The signage industry relies heavily on cold lamination films for outdoor applications, where UV protection and weather resistance are crucial for maintaining professional appearance and legibility over time. Retail businesses employ these films for point-of-purchase displays, product packaging enhancement, and promotional materials that require frequent handling and environmental exposure. Healthcare facilities use cold lamination films to protect patient information, medical charts, and instructional materials that must withstand frequent cleaning and sanitization procedures. Cold lamination films excel in food service applications where moisture resistance and easy cleaning are essential for menu boards, safety signage, and promotional displays. The technology adapts seamlessly to specialty applications such as museum artifact preservation, where UV protection and chemical stability are paramount for long-term conservation efforts. Industrial environments benefit from cold lamination films' chemical resistance properties, protecting safety labels, equipment identification tags, and procedural instructions from exposure to harsh chemicals and extreme conditions. Marine and outdoor recreation industries depend on cold lamination films for weather-resistant charts, maps, and instructional materials that must perform reliably in challenging environmental conditions. The automotive industry uses these films for protecting diagnostic charts, service manuals, and promotional materials in service areas exposed to oils, solvents, and temperature fluctuations.