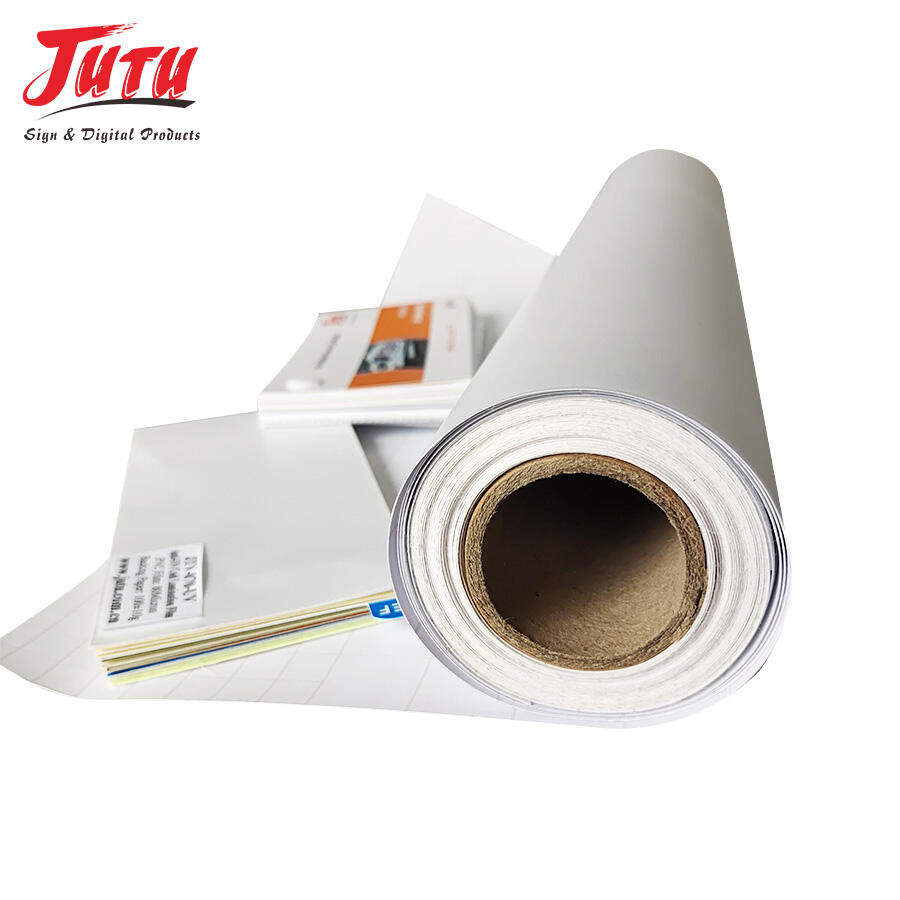

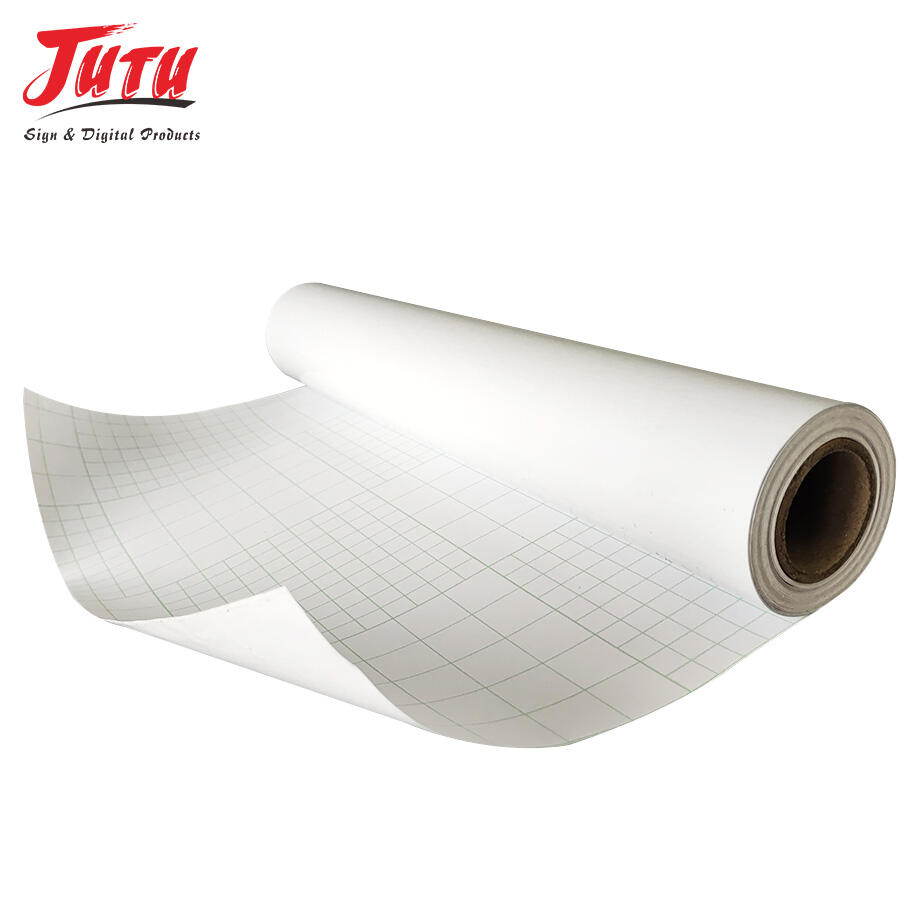

monomeric cold lamination film

Monomeric cold lamination film represents a revolutionary advancement in protective coating technology, offering exceptional durability and versatility for various commercial and industrial applications. This specialized film material consists of a single polymer layer structure that provides superior adhesion properties while maintaining cost-effectiveness and ease of application. The monomeric cold lamination film utilizes advanced adhesive technology that activates at room temperature, eliminating the need for heat-based application processes that can damage sensitive substrates. The primary function of monomeric cold lamination film centers on protecting printed materials, graphics, and surfaces from environmental factors including UV radiation, moisture, abrasion, and chemical exposure. Its technological features include excellent optical clarity, maintaining vibrant colors and sharp image quality while providing robust protection. The film demonstrates remarkable conformability, allowing it to adhere smoothly to curved surfaces and complex geometries without creating air bubbles or wrinkles. Application versatility makes monomeric cold lamination film suitable for outdoor signage, vehicle graphics, architectural elements, and retail displays. The film's pressure-sensitive adhesive system ensures reliable bonding to various substrates including vinyl, paper, metal, and plastic surfaces. Temperature resistance capabilities enable the film to perform consistently across diverse climate conditions, maintaining adhesive strength and optical properties. The manufacturing process incorporates quality control measures that ensure uniform thickness distribution and consistent adhesive coating, resulting in predictable performance characteristics. Monomeric cold lamination film offers excellent printability compatibility, working seamlessly with digital printing technologies including eco-solvent, latex, and UV-curable inks. The film structure provides dimensional stability, preventing shrinkage or expansion that could compromise the integrity of applied graphics. Environmental considerations include recyclability options and compliance with industry standards for sustainable manufacturing practices. Installation efficiency benefits from the cold application process, reducing labor time and equipment requirements compared to thermal lamination alternatives.