Versatile Application Compatibility

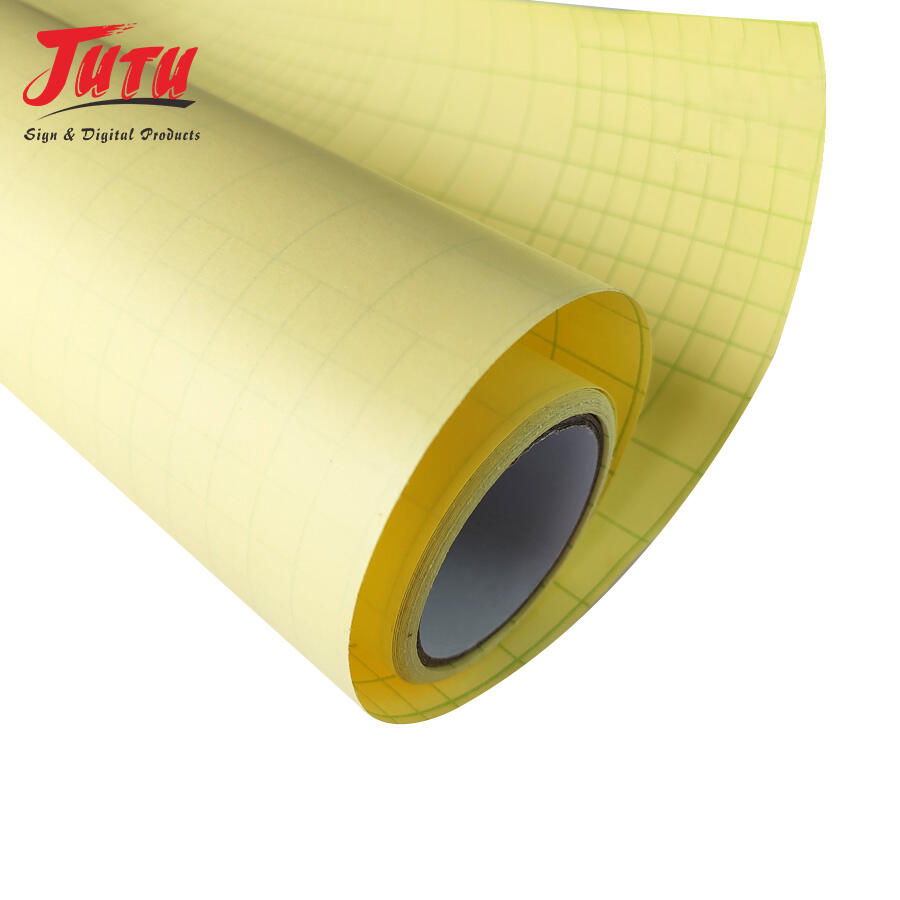

Cold lamination film roll demonstrates exceptional versatility across diverse industries and applications, making it an indispensable solution for businesses requiring flexible, reliable lamination capabilities. The broad material compatibility of cold lamination film roll extends to numerous substrates including paper, cardstock, vinyl, fabric, metal foils, and synthetic materials, eliminating the need for multiple specialized lamination systems and simplifying inventory management. Digital printing compatibility represents a crucial advantage, as cold lamination film roll works seamlessly with all major printing technologies including inkjet, laser, thermal transfer, and screen printing without causing ink migration, color shifting, or substrate distortion. The scalability of cold lamination film roll applications ranges from small desktop units handling business cards and photographs to large format industrial systems processing architectural drawings, outdoor banners, and vehicle graphics. Thickness accommodation capabilities allow cold lamination film roll systems to handle materials ranging from thin papers to thick mounting boards without adjustment complications or quality compromises. Surface texture compatibility extends cold lamination film roll applications to smooth and textured surfaces, glossy and matte finishes, and even slightly irregular substrates that would challenge conventional lamination methods. Environmental adaptability ensures cold lamination film roll maintains performance standards across varying humidity levels, ambient temperatures, and atmospheric conditions commonly encountered in different geographic regions and seasonal variations. Industry-specific formulations of cold lamination film roll address specialized requirements such as food-safe applications, pharmaceutical labeling, automotive components, and marine environments where standard lamination films might fail. Finish options within cold lamination film roll product lines include gloss, matte, and specialty textures, allowing customization of final appearance to match specific aesthetic or functional requirements. Processing speed flexibility accommodates both high-volume production environments and precision applications requiring careful handling, making cold lamination film roll suitable for commercial print shops, in-house graphics departments, and specialized manufacturing facilities. Archive-quality variants of cold lamination film roll meet preservation standards for important documents, photographs, and historical materials, ensuring long-term protection without compromising access or legibility for future generations.