3d cold lamination film

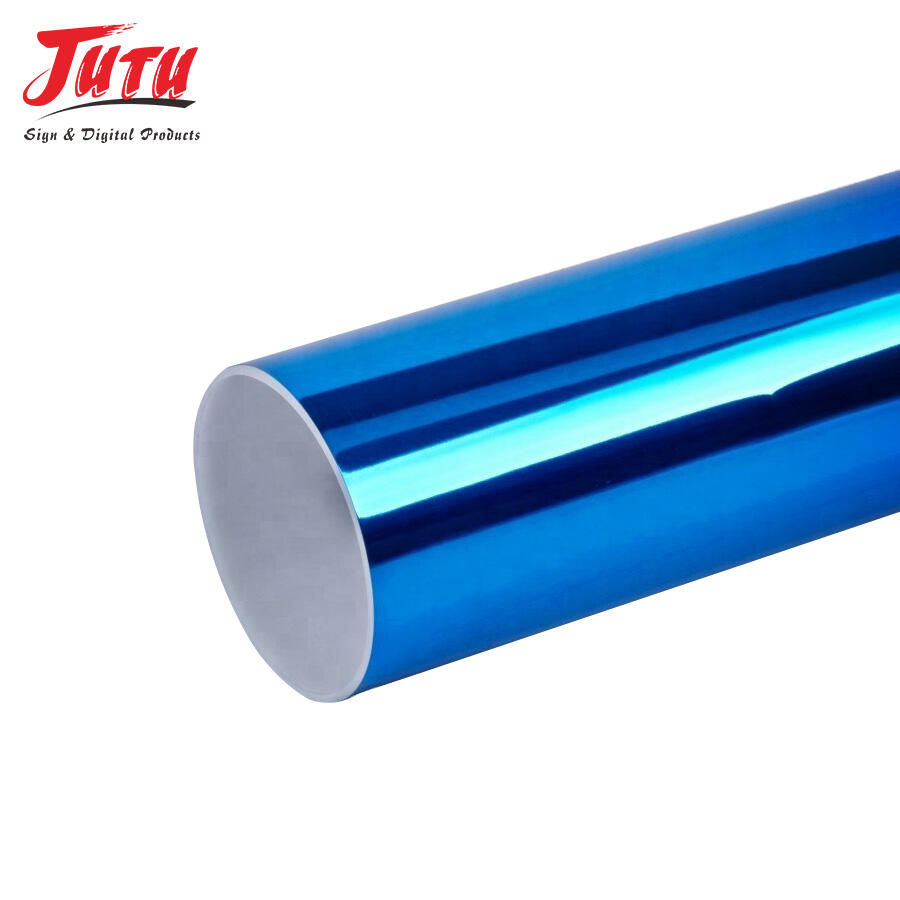

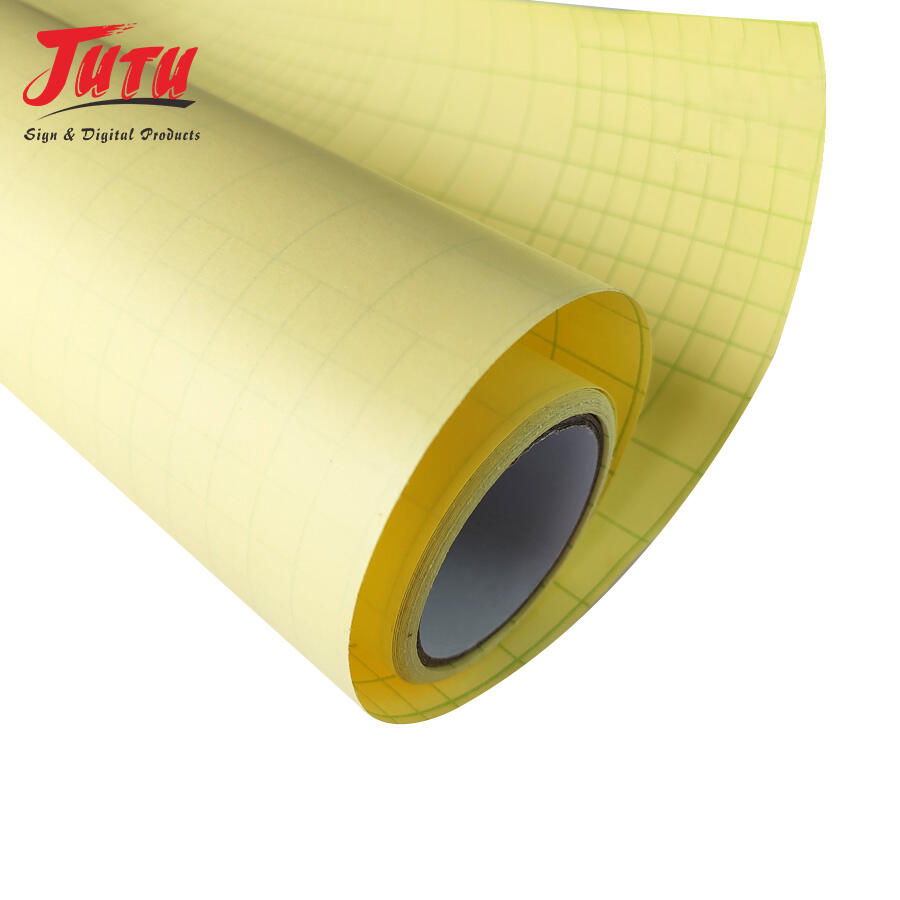

3D cold lamination film represents a revolutionary advancement in protective and decorative coating technology, offering superior surface enhancement without the need for heat application. This innovative material utilizes advanced adhesive formulations that activate at room temperature, making it an ideal solution for temperature-sensitive substrates and environments where traditional hot lamination processes are impractical. The 3D cold lamination film consists of multiple layers, including a clear protective top layer, an adhesive middle layer, and a release liner that ensures easy application and precise positioning. The film's three-dimensional texture capability allows it to conform to curved surfaces and complex geometries, providing comprehensive coverage that maintains visual clarity while delivering exceptional protection. Modern 3D cold lamination film incorporates cutting-edge polymer technology that ensures long-lasting durability, UV resistance, and chemical stability. The application process requires no specialized heating equipment, reducing energy consumption and operational costs while maintaining consistent quality results. This film technology serves multiple industries, from automotive and electronics to signage and architectural applications. The material's versatility extends to various substrate compatibility, including plastics, metals, glass, and composite materials. Advanced formulations of 3D cold lamination film offer customizable properties such as anti-glare surfaces, scratch resistance, and enhanced optical clarity. The manufacturing process ensures uniform thickness distribution and superior adhesive bonding strength, eliminating common issues like bubbling or edge lifting. Quality control measures integrated into production guarantee consistent performance characteristics across different batches. The 3D cold lamination film technology continues evolving with environmental considerations, featuring eco-friendly formulations that meet stringent regulatory standards while maintaining superior performance metrics.