Superior Protection Technology

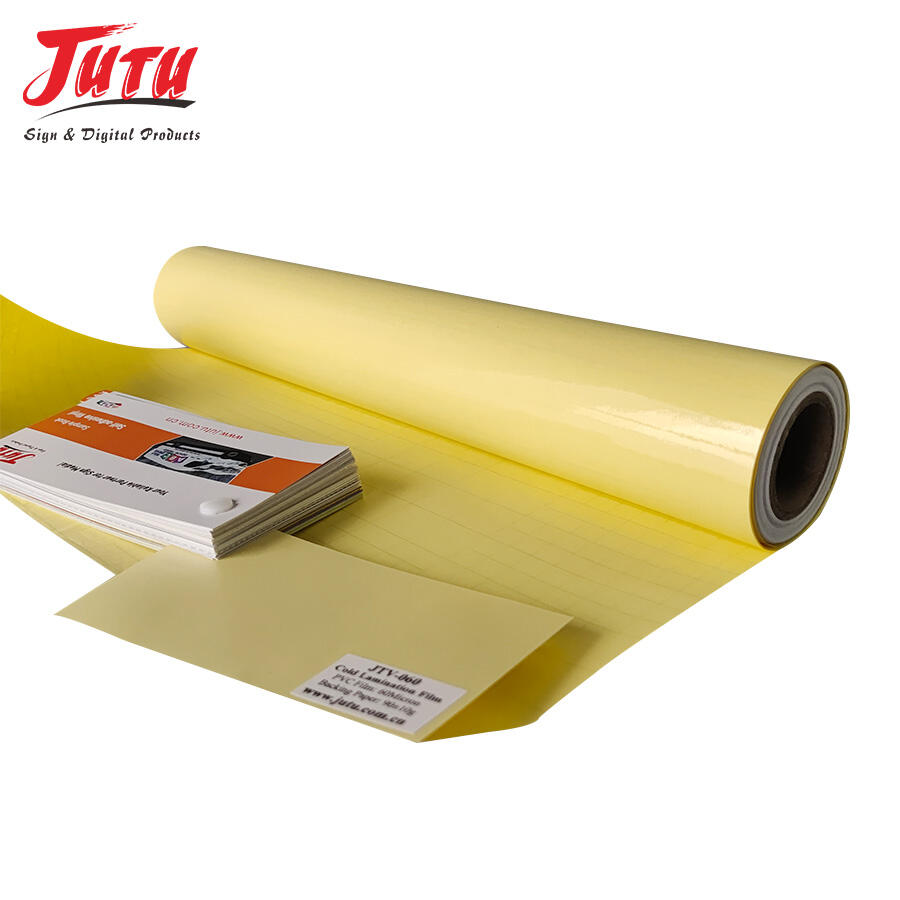

The advanced protection capabilities of glossy cold laminating film stem from its sophisticated multi-layer construction designed to shield documents from environmental hazards while maintaining optimal visual quality. This protective barrier system incorporates UV-blocking compounds that prevent harmful radiation from degrading printed inks and substrate materials, ensuring color fidelity remains intact for decades rather than months. The chemical-resistant topcoat repels moisture, oils, and common cleaning agents, making protected documents suitable for frequent handling in demanding environments. Laboratory testing demonstrates remarkable resistance to temperature fluctuations, preventing expansion and contraction that could compromise adhesive bonds or cause surface distortion. The glossy surface layer acts as a sacrificial barrier, absorbing minor impacts and scratches that would otherwise damage underlying documents permanently. This protection extends beyond physical threats to include biological hazards, as the sealed surface prevents bacterial growth and mold formation that typically occur in humid conditions. The barrier properties effectively block oxygen transmission, significantly slowing oxidation processes that cause paper yellowing and brittleness over time. Static electricity resistance prevents dust accumulation and maintains document cleanliness without requiring frequent maintenance. The protective qualities prove especially valuable for archival applications where document preservation spans generations, making glossy cold laminating film an essential tool for libraries, museums, and historical societies. Fire-retardant additives incorporated into the film structure provide additional safety benefits, slowing combustion rates and reducing flame spread in emergency situations. The comprehensive protection offered by this technology ensures that important documents, certificates, identification materials, and artistic works maintain their original appearance and structural integrity regardless of storage conditions or handling frequency.