cold laminating top glossy

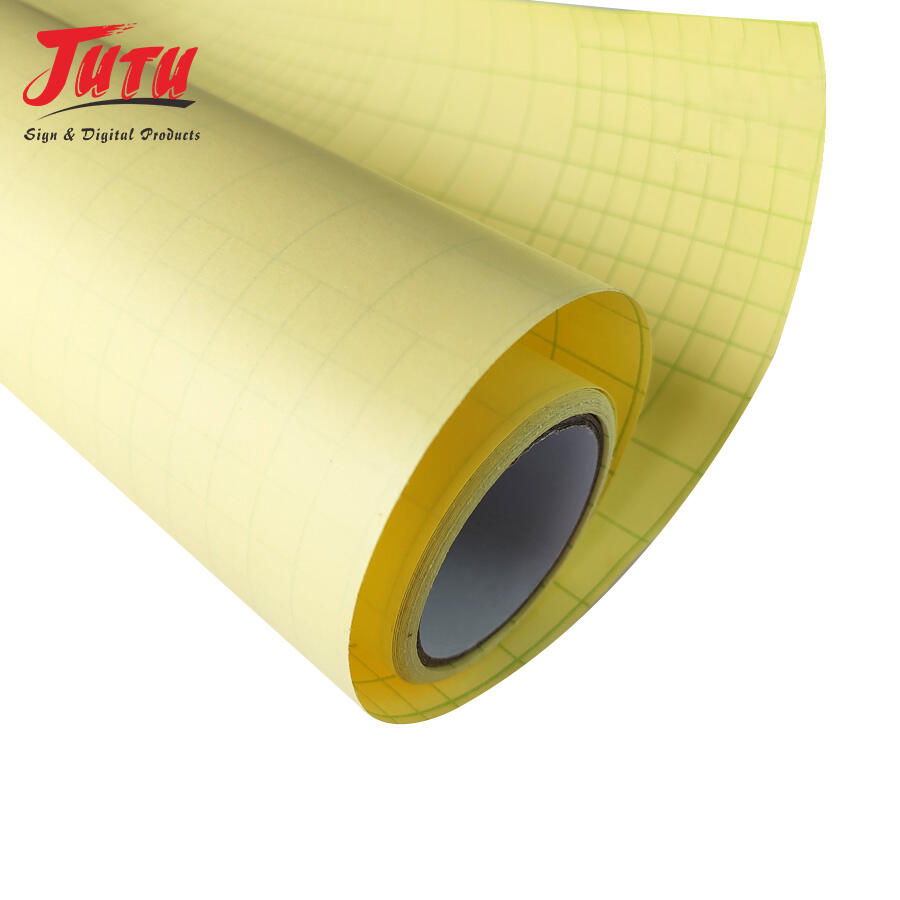

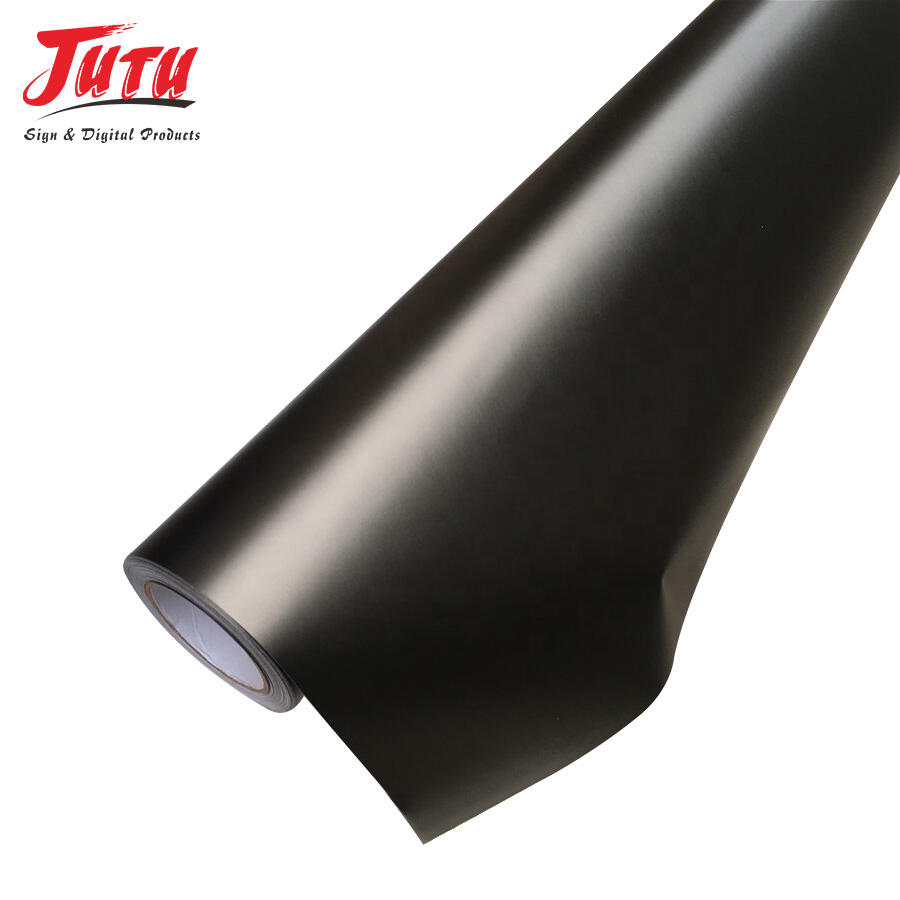

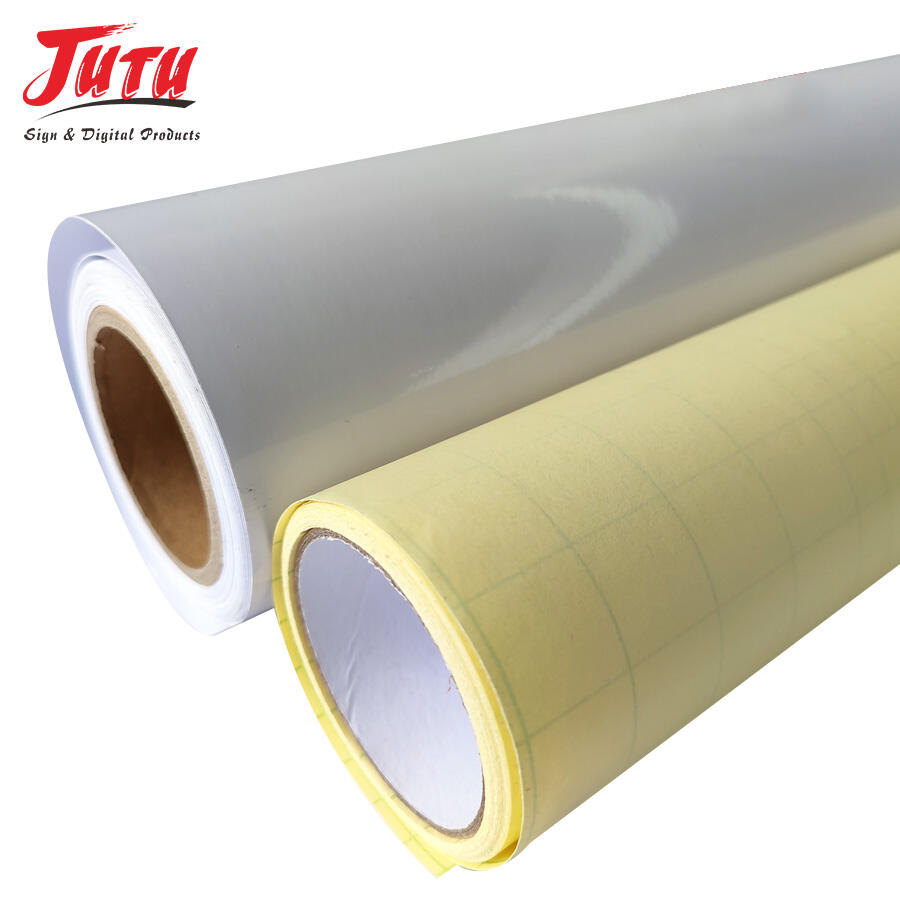

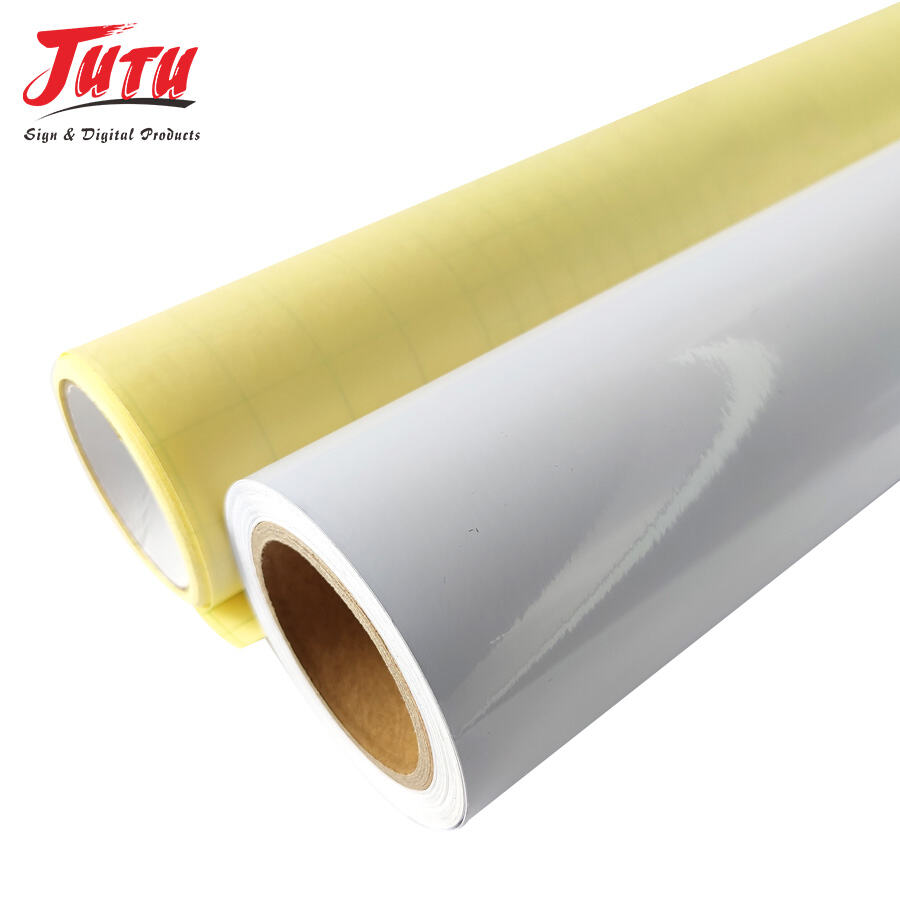

Cold laminating top glossy represents a cutting-edge surface protection technology that transforms ordinary materials into premium-quality finished products. This innovative laminating solution utilizes pressure-sensitive adhesive systems that bond permanently to substrates without requiring heat activation, making it an ideal choice for temperature-sensitive materials and high-volume production environments. The cold laminating top glossy film features a crystal-clear, high-gloss surface that enhances visual appeal while providing exceptional durability and protection against environmental factors. The technology employs advanced polymer formulations that deliver superior optical clarity, ensuring that underlying graphics, text, and images remain vibrant and sharp. The adhesive backing creates a secure bond with various substrates including paper, cardboard, vinyl, and synthetic materials, establishing a protective barrier that resists moisture, UV radiation, scratches, and general wear. Manufacturing processes incorporate precision coating techniques that guarantee uniform thickness and consistent adhesive distribution across the entire film surface. The cold laminating top glossy system operates effectively at room temperature, eliminating energy costs associated with heated laminating equipment while reducing processing time and increasing productivity. Quality control measures ensure that each roll meets stringent standards for clarity, adhesion strength, and surface smoothness. The film structure consists of multiple layers, including a protective release liner, pressure-sensitive adhesive layer, and the glossy topcoat that delivers the desired aesthetic and functional properties. Installation procedures are straightforward, requiring only appropriate pressure application to achieve complete adhesion. The cold laminating top glossy solution accommodates various thickness options to match specific application requirements, from lightweight document protection to heavy-duty signage applications. Storage stability remains excellent under normal conditions, maintaining adhesive properties and film integrity for extended periods without degradation or performance loss.