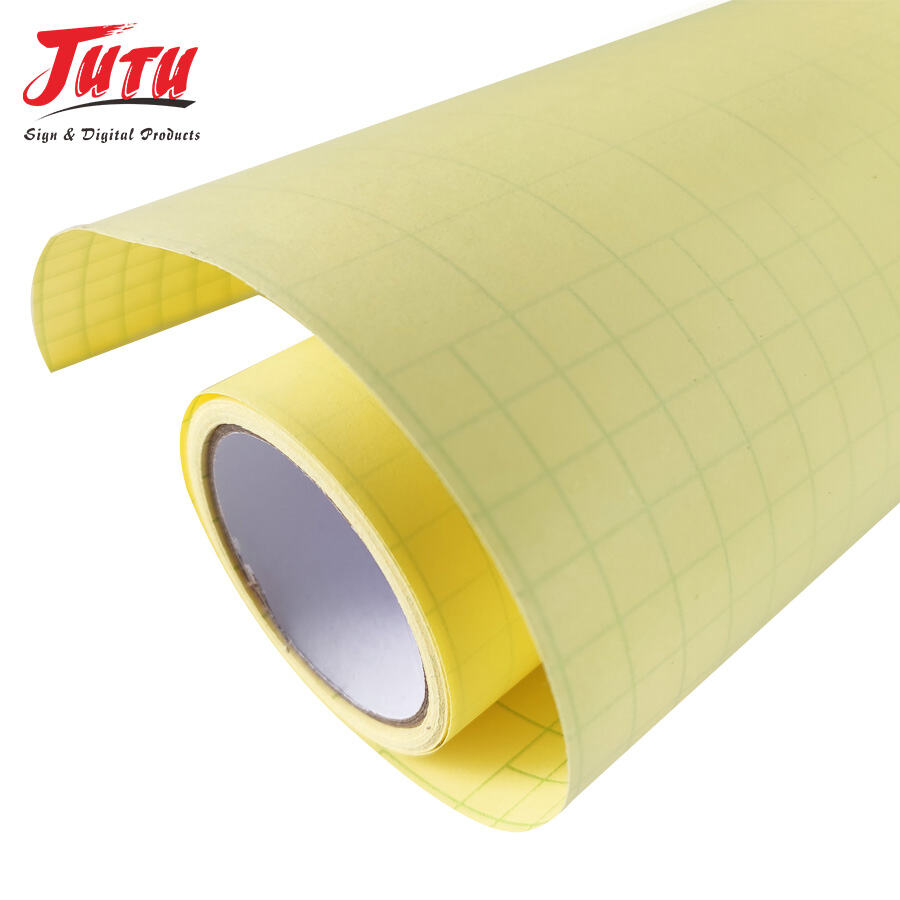

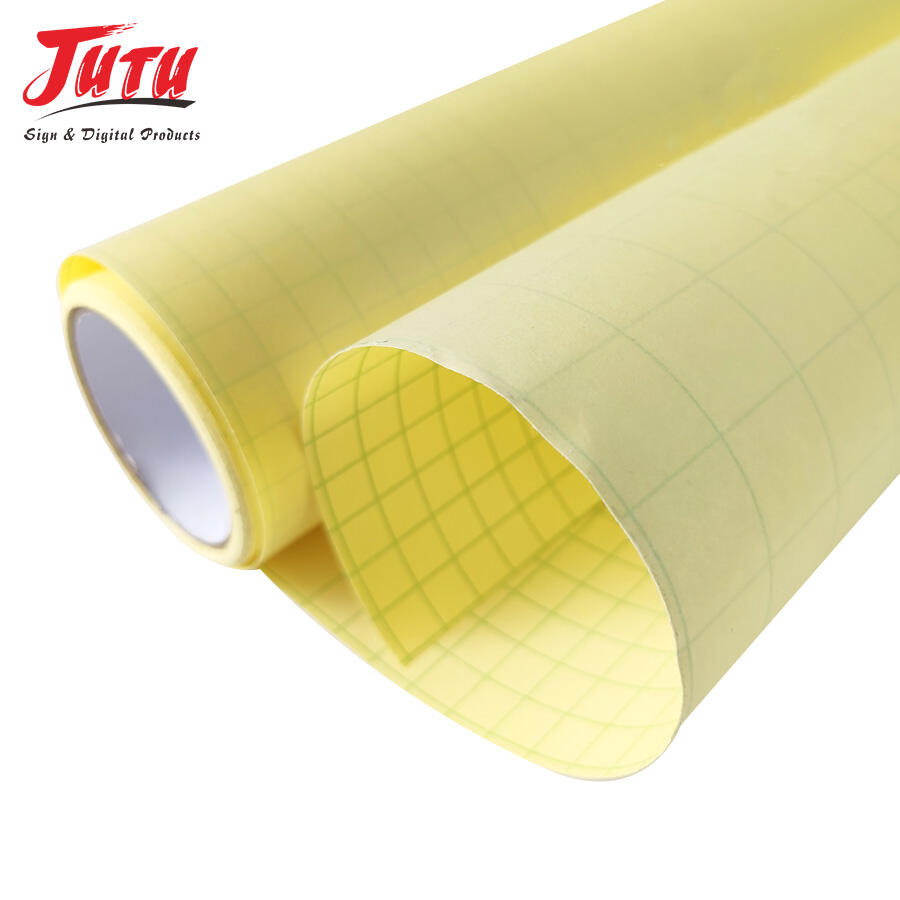

self adhesive cold lamination film

Self adhesive cold lamination film represents a revolutionary approach to document protection and enhancement that eliminates the need for heat-based lamination processes. This innovative material features a pressure-sensitive adhesive backing that bonds instantly to paper documents, photographs, signs, and various printed materials without requiring specialized heating equipment or professional lamination machines. The self adhesive cold lamination film consists of multiple layers including a clear protective face film, an adhesive layer, and a removable liner that ensures easy application and professional results every time. The technological foundation of self adhesive cold lamination film centers on advanced polymer chemistry that creates a permanent yet repositionable bond during initial placement. This unique characteristic allows users to adjust positioning before final adhesion occurs, preventing costly mistakes and material waste. The film's optical clarity maintains the original appearance of printed materials while providing superior protection against moisture, dirt, fingerprints, and general wear. Manufacturing processes involve precision coating techniques that ensure uniform adhesive distribution and consistent thickness throughout each roll or sheet. Quality control measures guarantee that self adhesive cold lamination film meets strict industry standards for clarity, adhesion strength, and durability. The material's UV-resistant properties prevent yellowing and degradation over time, making it ideal for long-term document preservation. Applications for self adhesive cold lamination film span numerous industries and use cases. Educational institutions utilize this material to protect frequently handled teaching materials, student ID cards, and classroom displays. Retail environments benefit from enhanced product labels, promotional materials, and point-of-sale displays that withstand constant handling. Office environments rely on self adhesive cold lamination film for protecting important documents, creating durable reference materials, and enhancing presentation quality. Photography professionals and hobbyists appreciate the film's ability to preserve precious memories while maintaining image quality and color accuracy.