digital vinyl printing

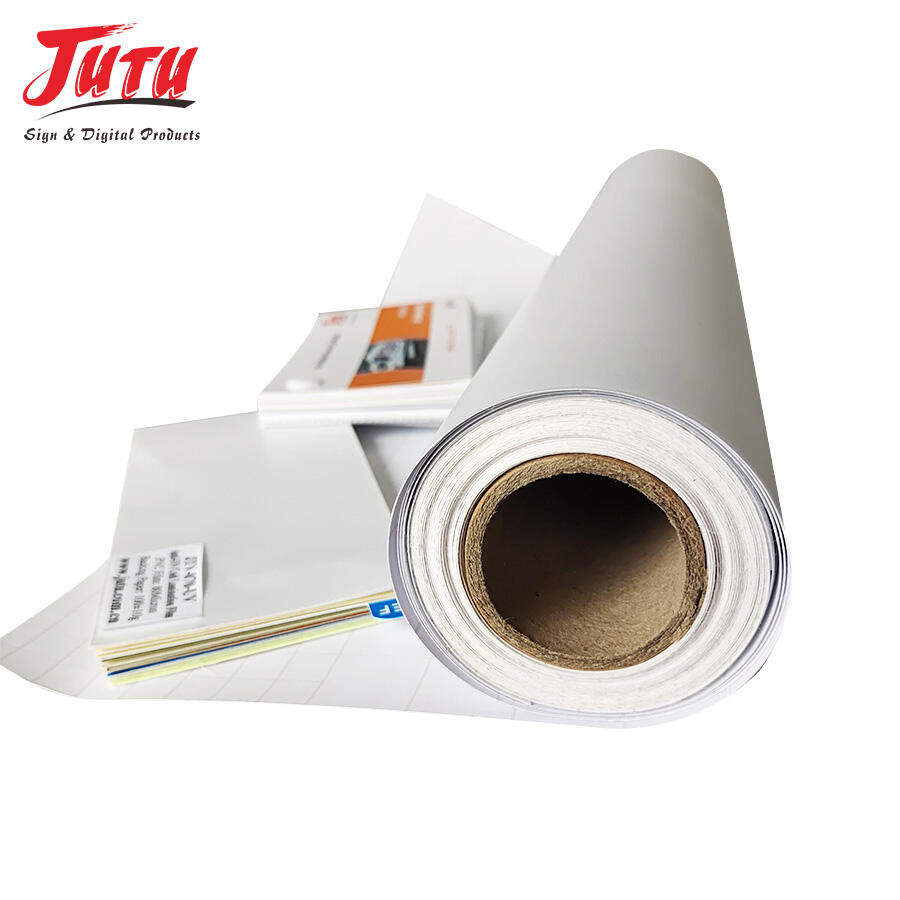

Digital vinyl printing represents a revolutionary advancement in modern printing technology, transforming how businesses and individuals create high-quality graphics for various applications. This cutting-edge process combines digital printing capabilities with vinyl materials to produce durable, vibrant, and versatile output suitable for countless commercial and personal uses. Digital vinyl printing utilizes specialized inkjet printers equipped with eco-solvent, latex, or UV-curable inks to create precise images directly onto vinyl substrates. The technology employs advanced print heads that deliver microscopic droplets of ink with exceptional accuracy, ensuring sharp details and smooth color gradients. Modern digital vinyl printing systems feature variable dot technology, allowing for optimal ink placement and superior image quality across different vinyl types. The process begins with digital file preparation, where artwork is processed through sophisticated RIP software that manages color profiles, print settings, and material specifications. This digital workflow eliminates traditional film separations and plate-making processes, streamlining production significantly. Digital vinyl printing accommodates various vinyl types, including calendered, cast, reflective, and specialty films. Each material offers unique characteristics suited for specific applications, from short-term promotional graphics to long-term architectural installations. The printing process maintains consistent quality across runs, whether producing single pieces or large quantities. Temperature and humidity controls ensure optimal printing conditions, while automated media handling systems maintain precise registration throughout production. Color management systems integrated into digital vinyl printing workflows guarantee accurate color reproduction and consistency across different jobs and reprints. The technology supports both solvent-based and eco-friendly ink formulations, allowing businesses to choose environmentally conscious options without compromising quality. Digital vinyl printing serves diverse industries including automotive, architecture, retail, healthcare, education, and entertainment. Applications range from vehicle wraps and building graphics to point-of-purchase displays and safety signage, demonstrating the versatility of this printing method.