Exceptional Versatility and Application Flexibility

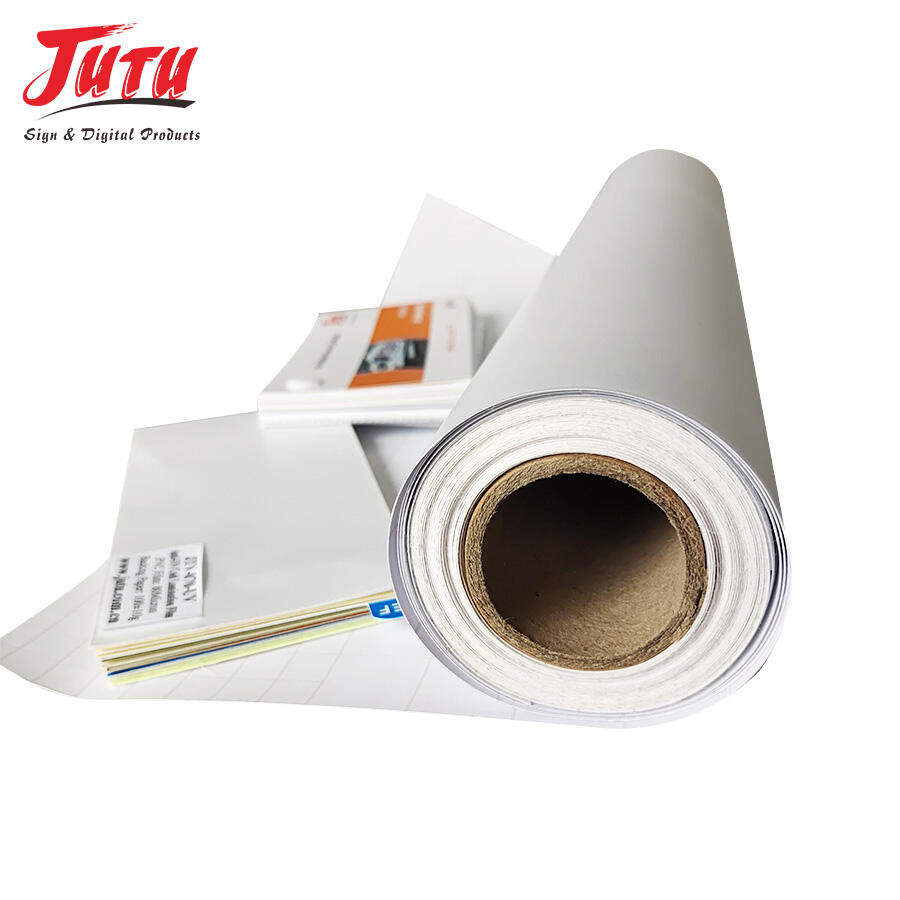

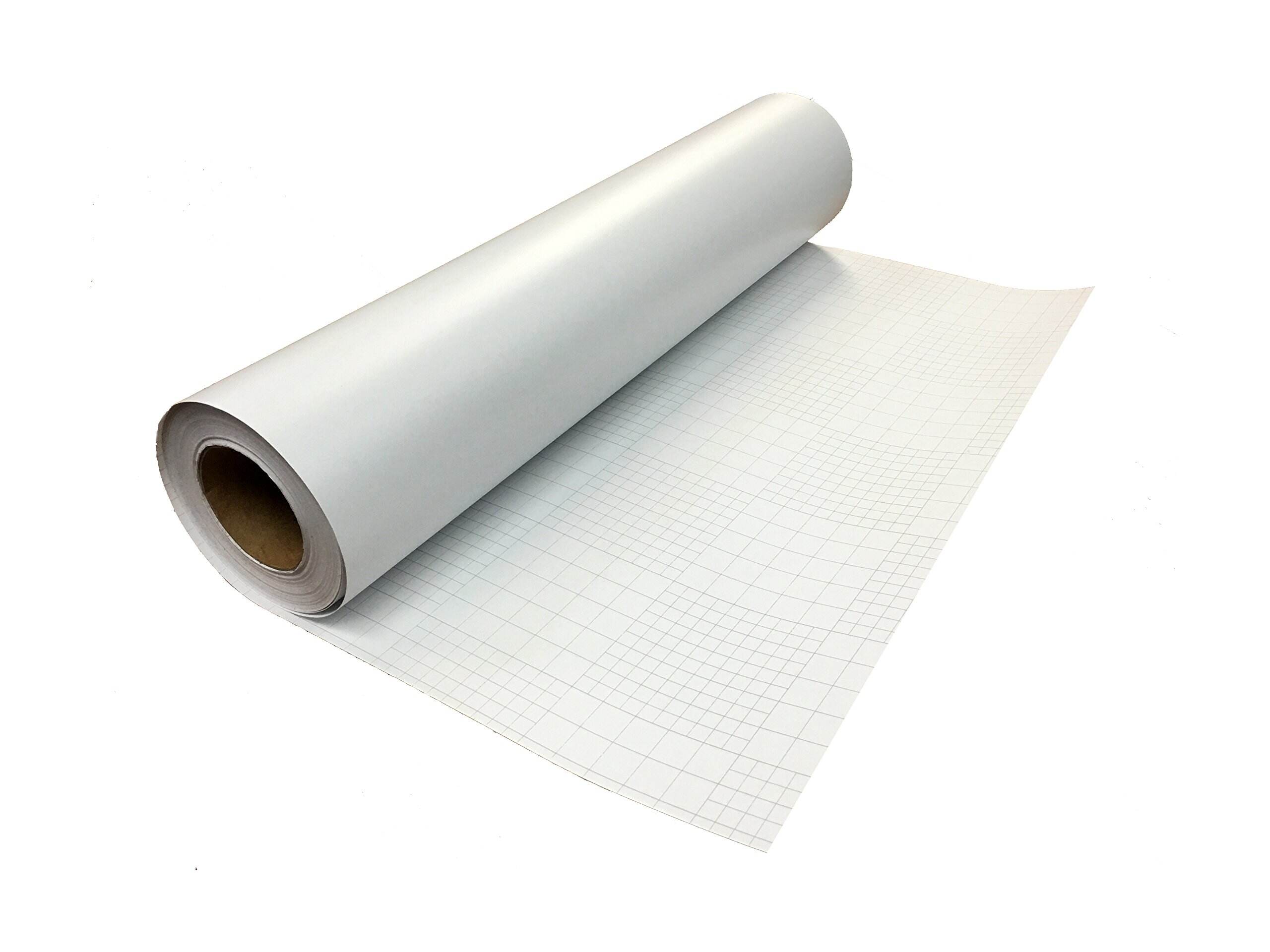

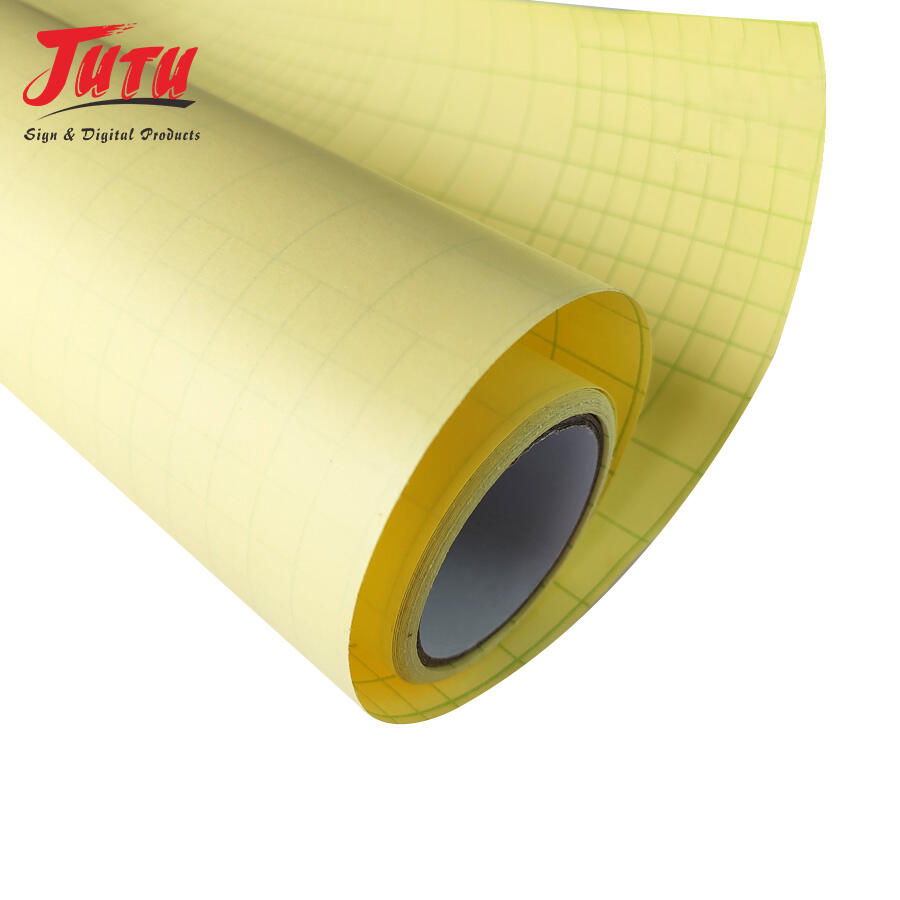

The versatility of glitter cold lamination film extends across an impressive range of materials, applications, and industries, making it a truly universal solution for protection and enhancement needs. This flexibility stems from its carefully engineered adhesive system that bonds effectively to diverse substrates including various paper grades, photographic papers, synthetic materials, and specialty substrates without requiring surface preparation or primer applications. The film accommodates materials of different thicknesses, from thin tissue papers to heavy cardstock, maintaining consistent adhesion and appearance quality across the entire range. Temperature sensitivity is eliminated through the cold application process, making it safe for thermal-sensitive materials such as digital prints, photographs processed with heat-sensitive chemicals, and documents printed with temperature-reactive inks. The application process adapts to different production environments, from small craft operations to large-scale commercial printing facilities, without requiring specialized equipment beyond basic laminating tools. Roll formats enable continuous processing for high-volume applications, while sheet formats provide convenience for smaller projects and custom sizing requirements. The film's conformability allows it to follow surface contours and textures, making it effective for materials with embossed elements, textured surfaces, or dimensional features that would challenge rigid protection systems. Color coordination options enable matching or contrasting with existing design elements, providing creative flexibility that enhances rather than competes with original artwork or messaging. The transparency level maintains readability while adding protective and decorative benefits, ensuring the enhanced materials continue to serve their intended communication purposes. Processing compatibility extends to various finishing operations including cutting, perforating, folding, and binding, allowing laminated materials to integrate seamlessly into existing workflows. Storage and handling characteristics remain favorable after lamination, with materials maintaining their original filing and organizational properties. The film's stability across different environmental conditions ensures consistent performance whether materials are used indoors, outdoors, or in specialized environments with controlled atmospheres. This exceptional versatility eliminates the need for multiple protection systems and reduces inventory complexity while providing comprehensive solutions for diverse application requirements. The adaptability to different user skill levels makes it accessible to both professional operators and occasional users who need reliable results without extensive training or experience.